Preparation method of high-purity zinc phosphide

A zinc phosphide, high-purity technology, applied in phosphide and other directions, can solve the problems of high investment cost, products can not meet high-purity requirements, and low yield of vacuum thermal decomposition method, and achieve the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1, a kind of preparation method of high-purity zinc phosphide, comprises the steps:

[0042] 1) Quartz tube pretreatment:

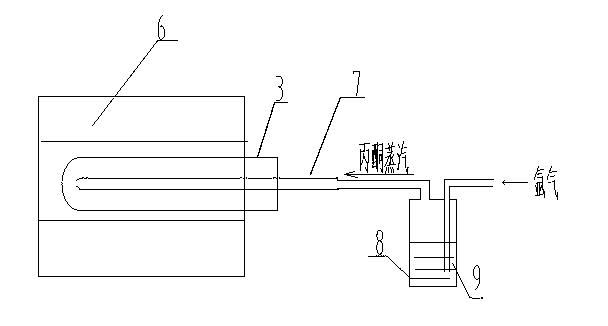

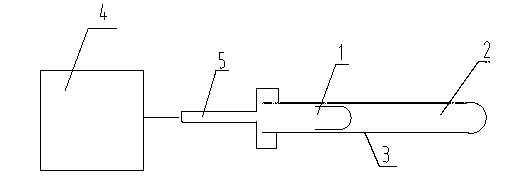

[0043] To clean the quartz tube, first wash it with alkaline water, wash it with high-purity water until it is neutral, then soak it in aqua regia for 24 hours, and then wash it with high-purity water until it is neutral. Before loading, pre-coat a layer of carbon film on the inner wall of the quartz tube; pre-coat carbon The film method is to use high-purity argon to transport acetone vapor into the quartz tube at a constant temperature of 900 ° C, and the acetone is cracked to coat the quartz tube with a carbon film. The length of the quartz tube is 60 cm, the diameter is 40 mm, and the thickness of the tube wall is 3 mm.

[0044] 2) Ingredients:

[0045] 21) Raw material preparation: Pick a red phosphorus block with a diameter of 5-7mm and a purity of 6N into a ground glass bottle, and fill the bottle with argon gas with a purity of 5N as a pr...

Embodiment 2

[0055] 1, a kind of preparation method of high-purity zinc phosphide, comprises the steps:

[0056] 1) Quartz tube pretreatment:

[0057] To clean the quartz tube, first wash it with alkaline water, wash it with high-purity water until it is neutral, then soak it in aqua regia for 24 hours, and then wash it with high-purity water until it is neutral. Before loading, pre-coat a layer of carbon film on the inner wall of the quartz tube; pre-coat carbon The film method is to use high-purity argon to transport acetone vapor into the quartz tube at a constant temperature of 1100 ° C, and the acetone is cracked to coat the quartz tube with a carbon film. The length of the quartz tube is 60 cm, the diameter is 40 mm, and the thickness of the tube wall is 3 mm.

[0058] 2) Ingredients:

[0059] 21) Raw material preparation: Pick a red phosphorus block with a diameter of 8-10mm and a purity of 6N into a ground glass bottle, and fill the bottle with argon with a purity of 5N as a prot...

Embodiment 3

[0068] 1, a kind of preparation method of high-purity zinc phosphide, comprises the steps:

[0069] 1) Quartz tube pretreatment:

[0070] To clean the quartz tube, first wash it with alkaline water, wash it with high-purity water until it is neutral, then soak it in aqua regia for 24 hours, and then wash it with high-purity water until it is neutral. Before loading, pre-coat a layer of carbon film on the inner wall of the quartz tube; pre-coat carbon The film method is to use high-purity argon to transport acetone vapor into the quartz tube at a constant temperature of 1000 ° C, and the acetone is cracked to coat the quartz tube with a carbon film. The length of the quartz tube is 60 cm, the diameter is 40 mm, and the thickness of the tube wall is 3 mm.

[0071] 2) Ingredients:

[0072] 21) Raw material preparation: Pick a red phosphorus block with a diameter of not more than 7mm and a purity of 6N into a ground glass bottle, and fill the bottle with argon with a purity of 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com