Photocuring nano hybrid material, and synthesis method and application thereof

A technology of nano-hybrid materials and light-curing coatings, applied in the directions of polyether coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of dispersion and agglomeration, affecting process performance, and preparing light-curing nano-hybrid materials, etc. Achieve good solubility and dispersibility, excellent photocurability, and improve curing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

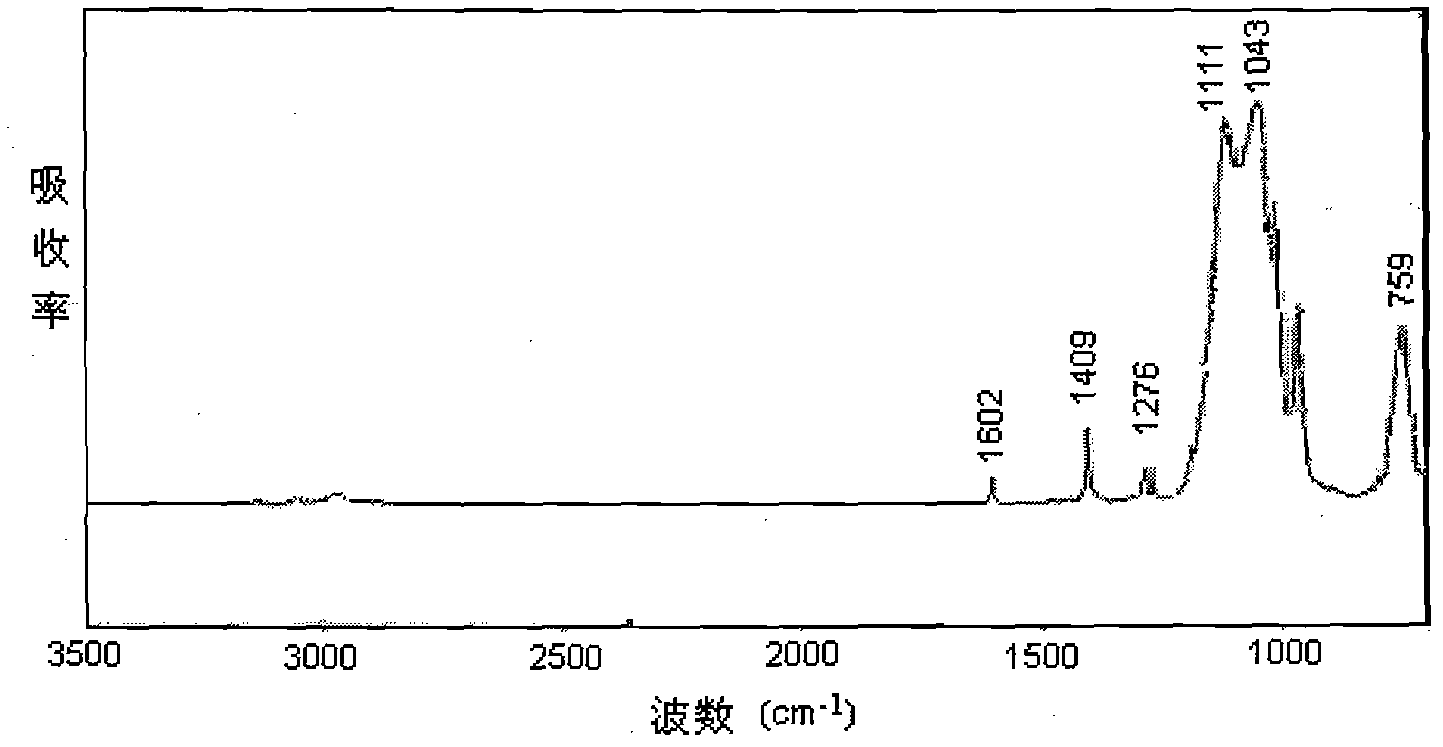

[0045] In another aspect, the present invention provides a method for preparing the above-mentioned photocurable nano-hybrid material with photocurable reactive groups, the method comprising: under nitrogen atmosphere, in the presence of a catalyst, in an organic solvent, at 20-80°C Under the temperature of 100°C, the siloxane with photocurable reactive groups is reacted with deionized water, the resulting hydrolyzate is polycondensed, and the solvent and other small molecules in the reaction system are removed under reduced pressure to obtain a photocurable reactive group. Curing nano-hybrid materials, wherein the siloxanes with photocurable reactive groups are selected from vinylsiloxanes, and (meth)acryloxysilanes, preferably gamma-methacryloxypropyltrimethyl Oxysilane.

[0046] In a preferred embodiment of the method for preparing a photocurable nano-hybrid material with a photocurable reactive group according to the present invention, the siloxane with a photocurable reac...

Embodiment 1

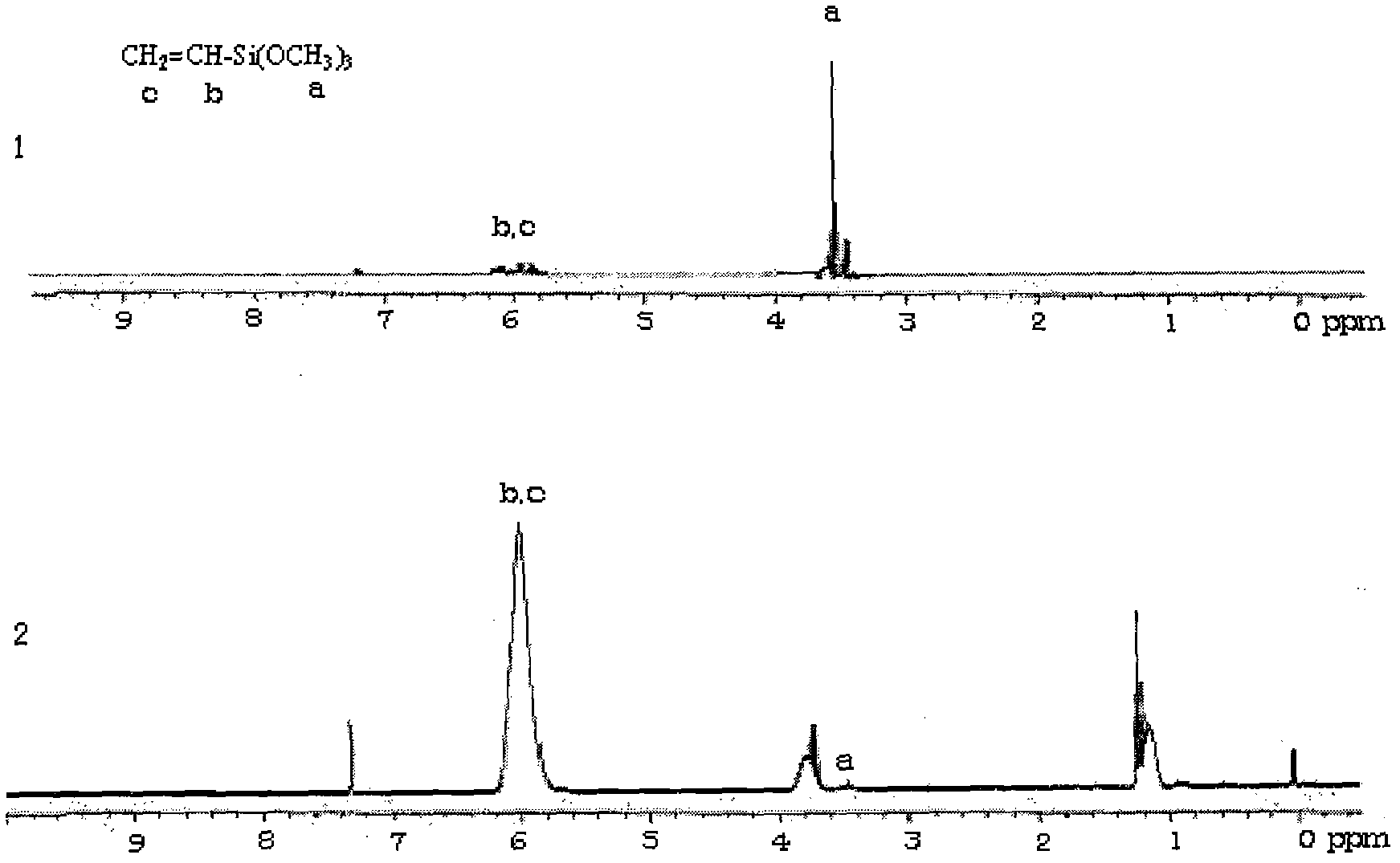

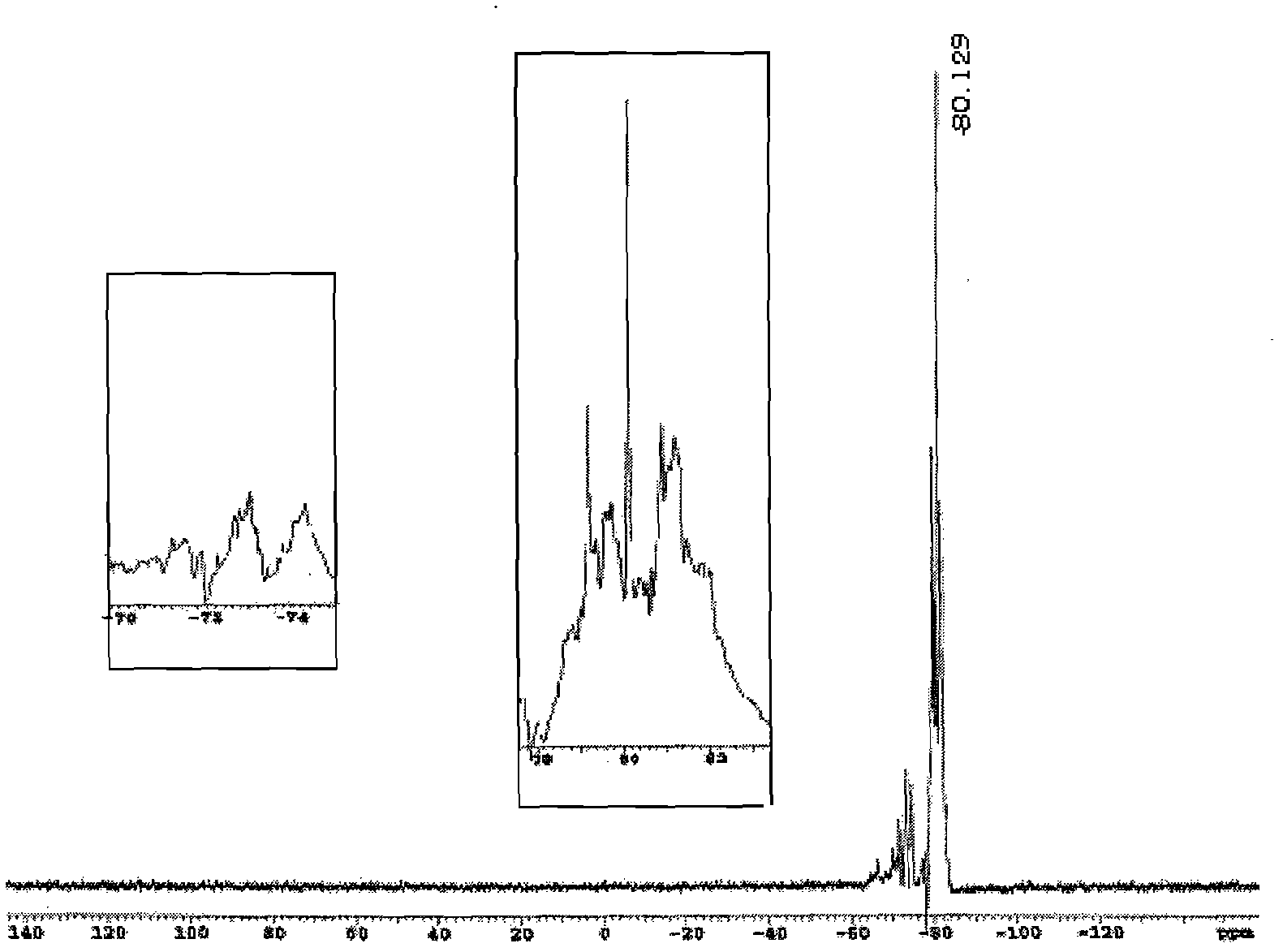

[0062] Example 1 Synthesis of photocurable nano-hybrid materials with photocurable reactive groups

[0063] Add 1.4 moles of ethanol solution, 0.05 moles of deionized water, and 0.01 moles of hydrochloric acid to 0.2 moles of vinylsiloxane, and react at 65°C. After 48 hours of reaction, remove the solvent and other small molecules under reduced pressure to obtain the product .

Embodiment 2

[0064] Example 2 Synthesis of photocurable nano-hybrid materials with photocurable reactive groups

[0065] Add 10 moles of ethanol solution, 0.5 moles of deionized water, and 0.01 moles of sulfuric acid to 1 mole of vinylsiloxane, and react at 40°C. After 10 hours of reaction, remove the solvent and other small molecules under reduced pressure to obtain the product .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com