Zinc powder-free water-based primer

A water-based primer and zinc powder technology, used in anti-corrosion coatings, coatings, etc., can solve the problems of high rust removal requirements for substrates, strict labor protection requirements, and high prices, so as to solve the problem of secondary rust removal and solve Health hazards and the effect of preventing hot zinc disease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

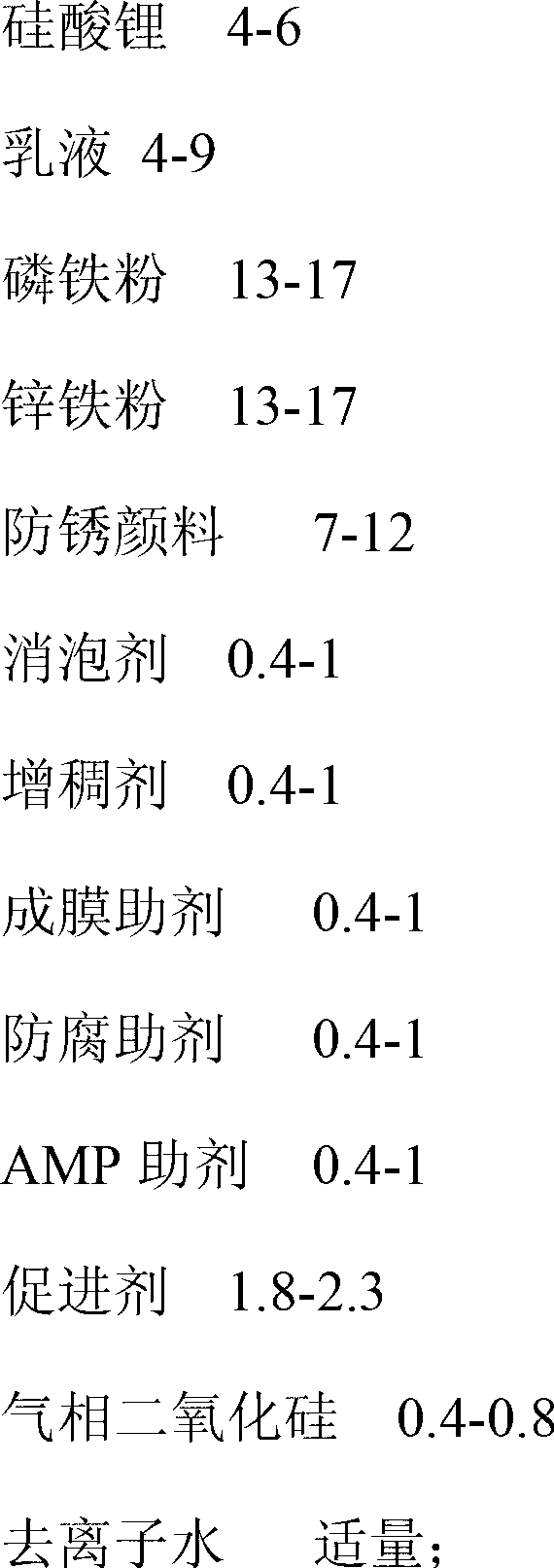

[0041] A kind of zinc-powder-free water-based primer comprises the following components in parts by weight:

[0042]

[0043]

[0044] Wherein, the addition amount of described water is that the paint-4 cup viscosity that is added to water-based primer is 50.

[0045] The preparation method procedure of the water-based primer includes: dispersing→stirring→paint mixing→inspection→filtering→packaging, and the construction method of the water-based primer is: directly painting the water-based primer.

Embodiment 2

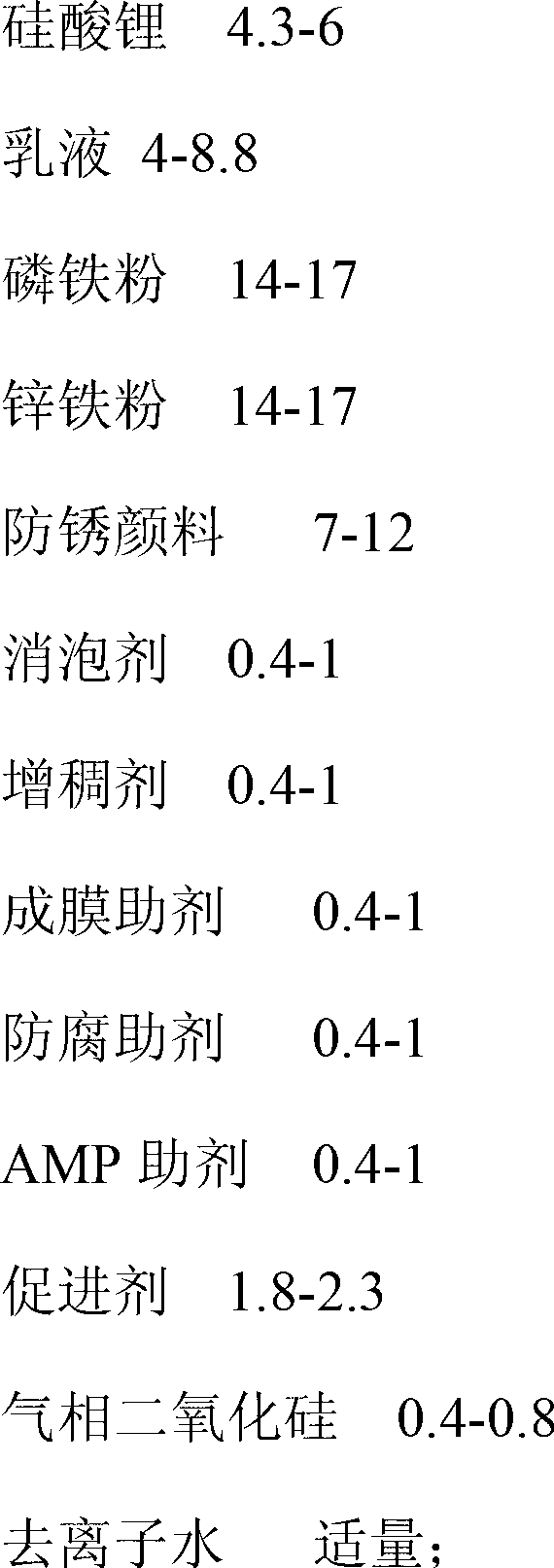

[0047] A kind of zinc-powder-free water-based primer comprises the following components in parts by weight:

[0048]

[0049] Wherein, the addition amount of described water is that the coating-4 cup viscosity that is added to water-based primer is 110.

[0050] The preparation method procedure of the water-based primer includes: dispersing→stirring→paint mixing→inspection→filtering→packaging, and the construction method of the water-based primer is: directly painting the water-based primer.

Embodiment 3

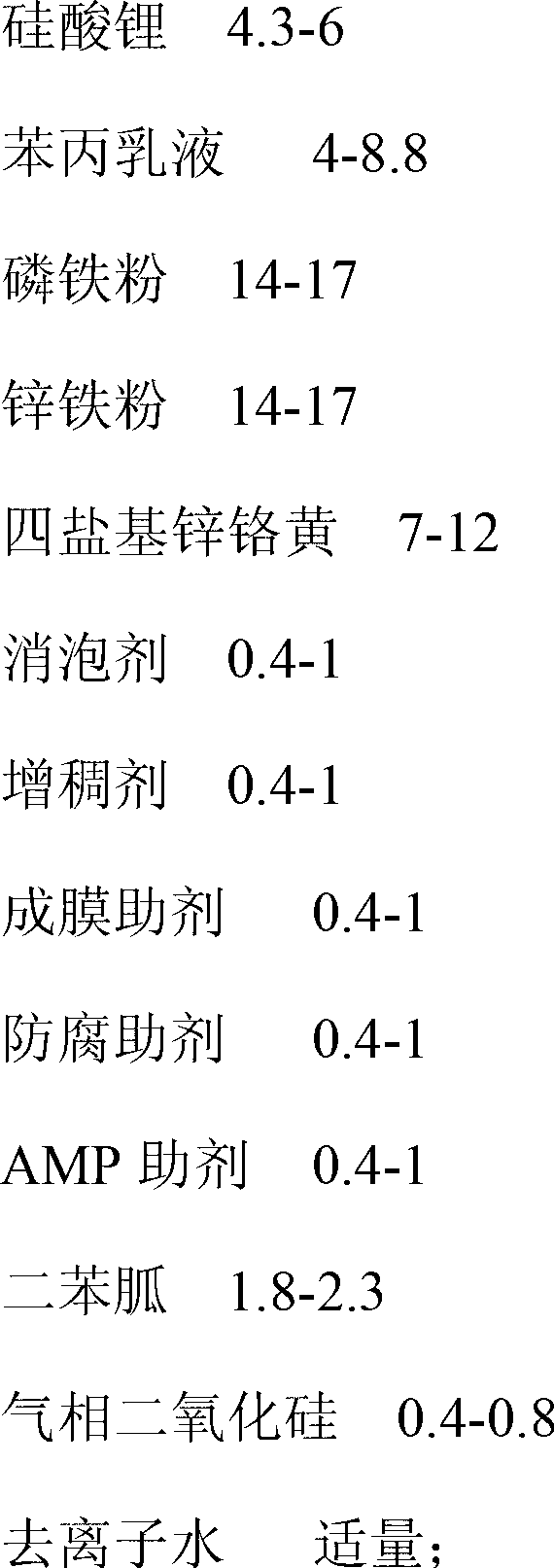

[0052] A kind of zinc-powder-free water-based primer comprises the following components in parts by weight:

[0053]

[0054] Wherein, the addition amount of described water is that the paint-4 cup viscosity that is added to water-based primer is 70.

[0055] The preparation method procedure of the water-based primer includes: dispersing→stirring→paint mixing→inspection→filtering→packaging, and the construction method of the water-based primer is: directly painting the water-based primer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com