A kind of technology of iron trichloride treatment lead matte

A technology of ferric chloride and lead matte, which is applied in the direction of improving process efficiency and the like, can solve the problems of high requirements on corrosion-resistant conditions of equipment materials, aggravating environmental burdens, increasing production costs, etc., and is beneficial to environmental protection and leaching time. The effect of short, short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The chemical composition of lead matte in a factory is as follows:

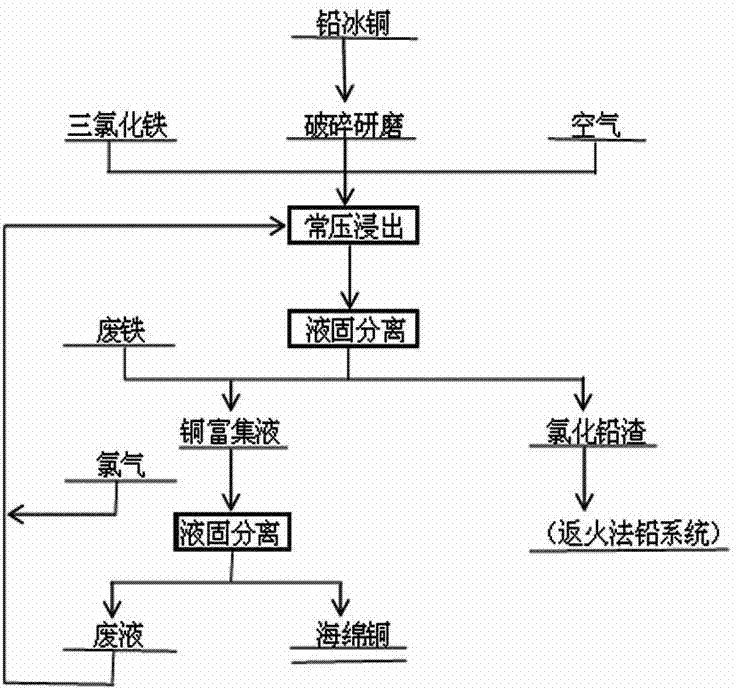

[0046] Pb: 7.83%, Cu: 29.38%, Fe: 36.22%, S: 20.07%, SiO 2 : 3.81%, CaO: 1.14%, Ag: 0.0993%, Zn: 1.11%, Te: 0.11%, Se: 0.21%. Implementation methods such as figure 1 As shown, after grinding the lead matte through an 80-mesh sieve, add the prepared FeCl 3 The leaching solution is fed into the air, the stirring speed is 300r / min, and the leaching is carried out under normal pressure. The leaching conditions are: using FeCl 3 Solution leaching, FeCl 3 The concentration is 300g / L, the liquid-solid ratio is 5:1, the temperature is 89°C, air is continuously fed in, the stirring speed is 300r / min, and the reaction time is 4 hours. The recovery rate of copper is 84.39%.

Embodiment 2

[0048]The chemical composition of lead matte in a factory is as follows:

[0049] Pb: 7.83%, Cu: 29.38%, Fe: 22.60%, S: 19.85%, SiO 2 : 3.02%, CaO: 1.54%, Ag: 0.1022%, Te: 0.19%, Se: 0.31%. Implementation methods such as figure 1 As shown, after grinding the lead matte block material, add the prepared FeCl 3 Leaching liquid, and feed into air, stirring speed is 500r / min, normal pressure leaching, the operation of leaching copper is exactly the same as embodiment 1, and its leaching condition is: adopt FeCl 3 Solution leaching, FeCl 3 The concentration is 350g / L, the liquid-solid ratio is 5:1, the temperature is 95°C, air is continuously introduced, the stirring speed is 350r / min, and the reaction time is 8 hours. The recovery rate of copper is 88.07%.

Embodiment 3

[0051] The chemical composition of lead matte in a factory is as follows:

[0052] Pb: 7.67%, Cu: 29.72%, Fe: 19.53%, S: 20.08%, SiO 2 : 4.52%, CaO: 0.97%, Ag: 0.0633%, Te: 0.17%, Se: 0.26%. Implementation methods such as figure 1 As shown, after grinding the lead matte block material, add the prepared FeCl 3 Leach solution, and feed into air, stirring speed is 300r / min, normal pressure leaching, the operation of leaching copper is exactly the same as embodiment 1, and its leaching condition is: adopt FeCl 3 Solution leaching, FeCl 3 The concentration is 400g / L, the liquid-solid ratio is 5:1, the temperature is 95°C, air is continuously fed in, the stirring speed is 300r / min, and the reaction time is 7.5 hours. The recovery rate of copper is 92.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com