Technology for recovering metallic copper from high-lead copper matte

A technology of metal copper and copper matte, applied in the direction of photography technology, photography auxiliary technology, process efficiency improvement, etc., to achieve the effect of strong process adaptability, high recovery rate and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

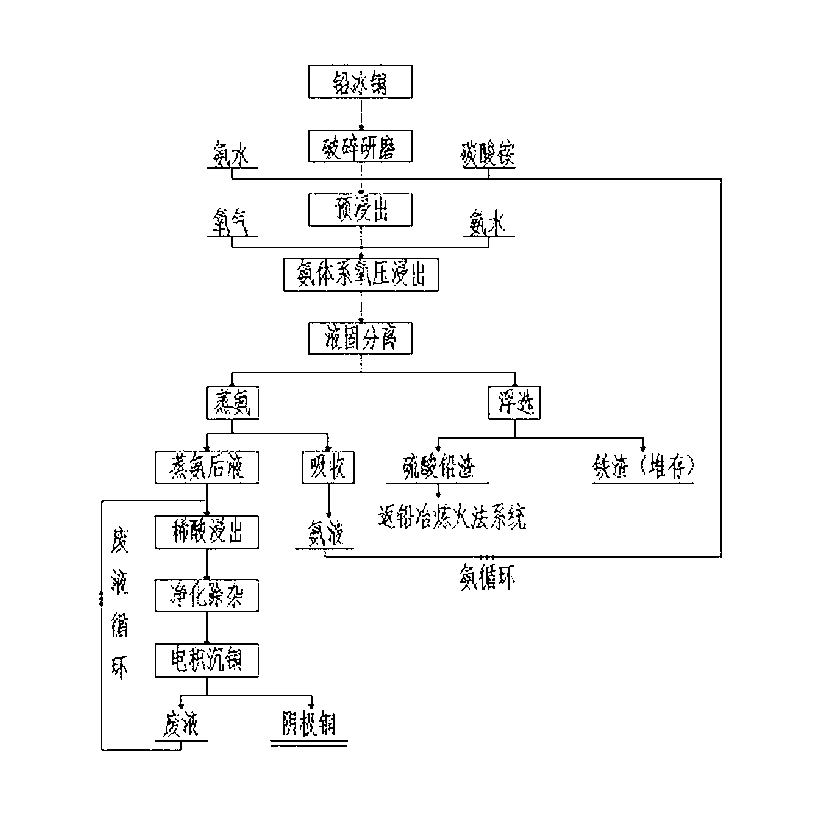

Image

Examples

Embodiment 1

[0033] The chemical composition of high lead copper matte in a factory is as follows, Pb: 15.64%, Cu: 34.38%, Fe: 17.51%, S: 11.54%, SiO 2 : 0.43%, CaO: 0.54%, Ag: 0.0122%, Au: 0.0064%, Se: 0.081%, Te: 0.015%.

[0034] Its specific process steps are as follows:

[0035] ① Crushing and grinding

[0036] The high-lead copper matte recovered from the pyrometallurgical lead smelting system is usually in the form of large blocks with different particle sizes after cooling. In order to ensure a high metal leaching rate, crushing or vibration grinding must be carried out. Usually, the jaw crusher is used for processing and sent to the ball mill to control the particle size of the block material below 100 mesh, and take 200 grams of the underscreen;

[0037] ②Ammonia-ammonium carbonate system pressure oxidation leaching

[0038] The high-lead copper matte is directly fed, and the ammonium carbonate solution is used to complete the pulping operation in the autoclave; a certain amou...

Embodiment 2

[0055] The chemical composition of high lead copper matte in a factory is as follows, Pb: 7.86%, Cu: 29.51%, Fe: 32.55%, S: 20.09%, SiO 2 : 1.57%, CaO: 0.88%, Ag: 0.0092%, Au: 0.0064%, Se: 0.053%, Te: 0.026%. Process this material by vibrating mill, sieve 100 mesh, get 200 grams of sieve. Prepare ammonia water-ammonium carbonate leaching solution 1400mL, NH 3 : NH 4 + =3:1, stirring and pre-leaching for 2 hours at room temperature. After the reaction, the pulp is sent to the autoclave, and 200mL of 30% ammonia water is added, and after the temperature is raised to a certain value, oxygen is introduced to oxidize and leaching copper. Its operating conditions: temperature 210°C, oxygen partial pressure 0.4MPa, total pressure 2.5MPa, liquid-solid ratio 8:1, stirring and leaching reaction for 2.5 hours. The copper leaching rate reached 99.65%, the lead leaching rate was 0.14%, and the iron leaching rate was 4.26%. After the liquid-solid separation, the copper ammonia solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com