Antibacterial biological activity stent and preparation method thereof

A biologically active and antibacterial biological technology, applied in the field of medical biomaterials, can solve the problems of antibacterial and biological activity and single function, and achieve the effect of improving mechanical properties and promoting vascularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

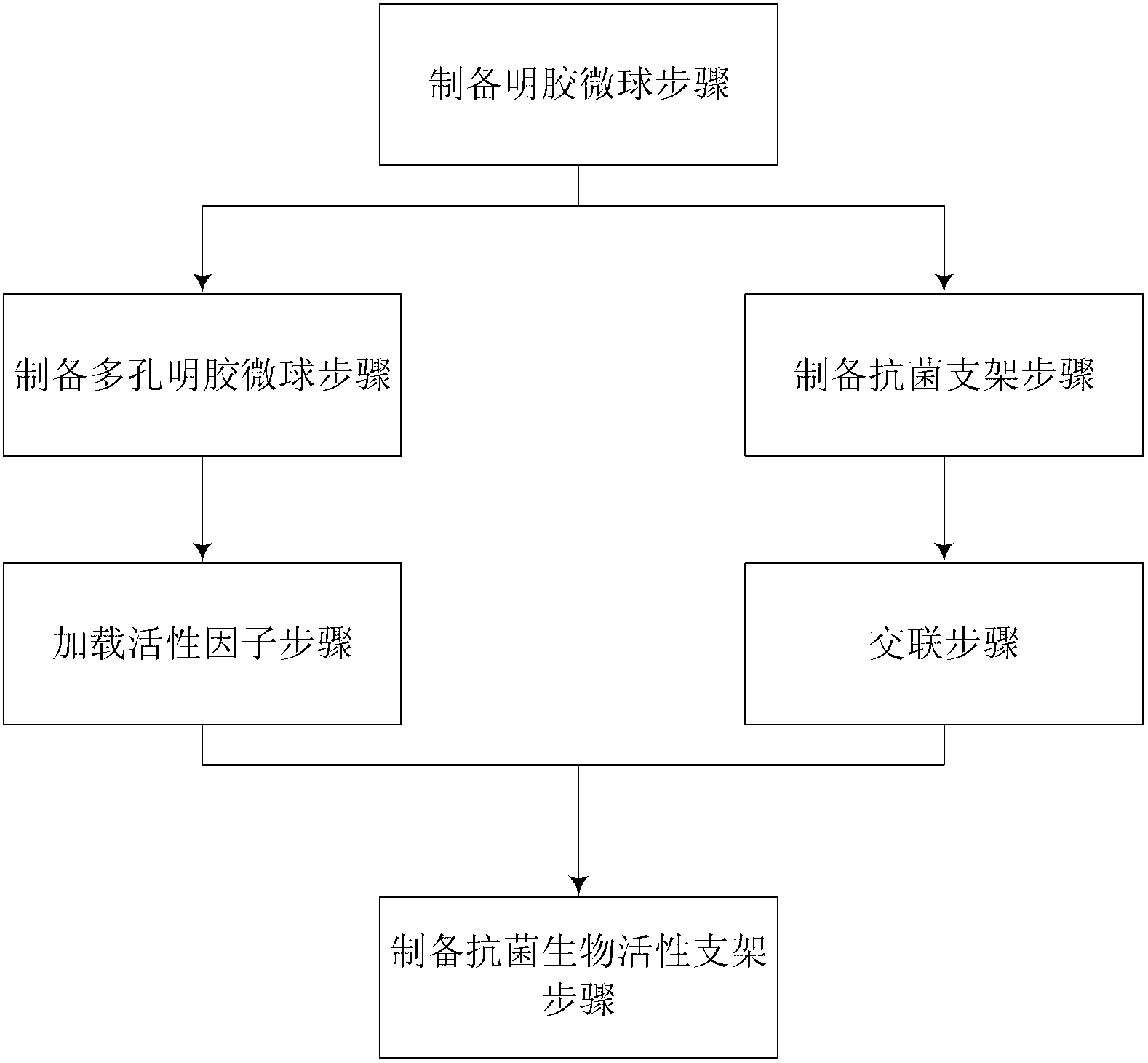

[0026] On the other hand, the present invention also provides a method for preparing the above-mentioned antibacterial bioactive scaffold, comprising the following steps:

[0027] The step of preparing gelatin microspheres is to prepare solid gelatin microspheres;

[0028] The step of preparing porous gelatin microspheres is to make the solid gelatin microspheres into porous gelatin microspheres;

[0029] In the active factor loading step, the active factor aqueous solution with a concentration of 0.01-150ug / ul is added dropwise to the porous gelatin microspheres. The amount of the active factor aqueous solution is preferably added dropwise to 20ul of the active factor aqueous solution per 2mg of porous gelatin microspheres, and the dropwise After the addition is completed, let it stand at room temperature, so that the active factor solution is fully impregnated on the dry microspheres, and the gelatin microspheres loaded with the active factor are obtained;

[0030] In the s...

Embodiment 1

[0039] 1. Preparation of gelatin microspheres

[0040] Take two parts of gelatin, add eight parts of distilled water to prepare gelatin with a concentration of 20% by mass, and dissolve it in a constant temperature water bath at 42°C for 1 hour. At the same time, take 300ml soybean oil and put it in a water bath at 42°C. Drop the gelatin solution into the oil at rp / min, stir for 10 minutes to form a water / oil emulsion, then gradually lower the temperature of the mixed emulsion from 42°C to 0°C, keep the temperature for 15 minutes every time the temperature drops by 10°C, and then add 200ml of acetone at 4°C , adjust the speed to 600rp / min, continue to stir for 1h, wash with acetone and collect by centrifugation at 3200rp / min, and finally soak in 1,4-ethylene oxide for 2 days, change the solvent three times a day, wash with deionized water, and then Freeze-dry for 2 days, and finally use a sieve to screen the gelatin microspheres with a particle size of 80-400 μm.

[0041] 2. ...

Embodiment 2

[0052] 1. Preparation of gelatin microspheres

[0053] Take four parts of gelatin, add six parts of distilled water to prepare a gelatin solution with a mass percentage of 40%, dissolve it in a constant temperature water bath at 50°C for 1 hour, and at the same time take 300ml of silicone oil in a water bath at 50°C. Drop the gelatin solution into the oil at a speed of 1 / min, stir for 10 minutes to form a water / oil emulsion, then gradually lower the temperature of the mixed emulsion from 50°C to 0°C, keep the temperature for 15 minutes every time the temperature drops by 10°C, then add 200ml of acetone at 4°C, Adjust the speed to 600rp / min, continue stirring for 1h, wash with acetone and collect by centrifugation at 3200rp / min, and finally soak in 1,4-ethylene oxide for 2 days, change the solvent three times a day; wash with deionized water, and then freeze Dry for 2 days, and finally use a sieve to screen the gelatin microspheres with a particle size of 80-400 μm.

[0054] 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com