Fluidized bed low-temperature granulation drying production system

A fluidized bed drying and production system technology, applied in the direction of drying gas arrangement, drying, drying machine, etc., can solve the problems of high operating cost, easy agglomeration, low softening point of powder, etc., and achieve reduction of tail gas emissions , Save energy consumption, reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

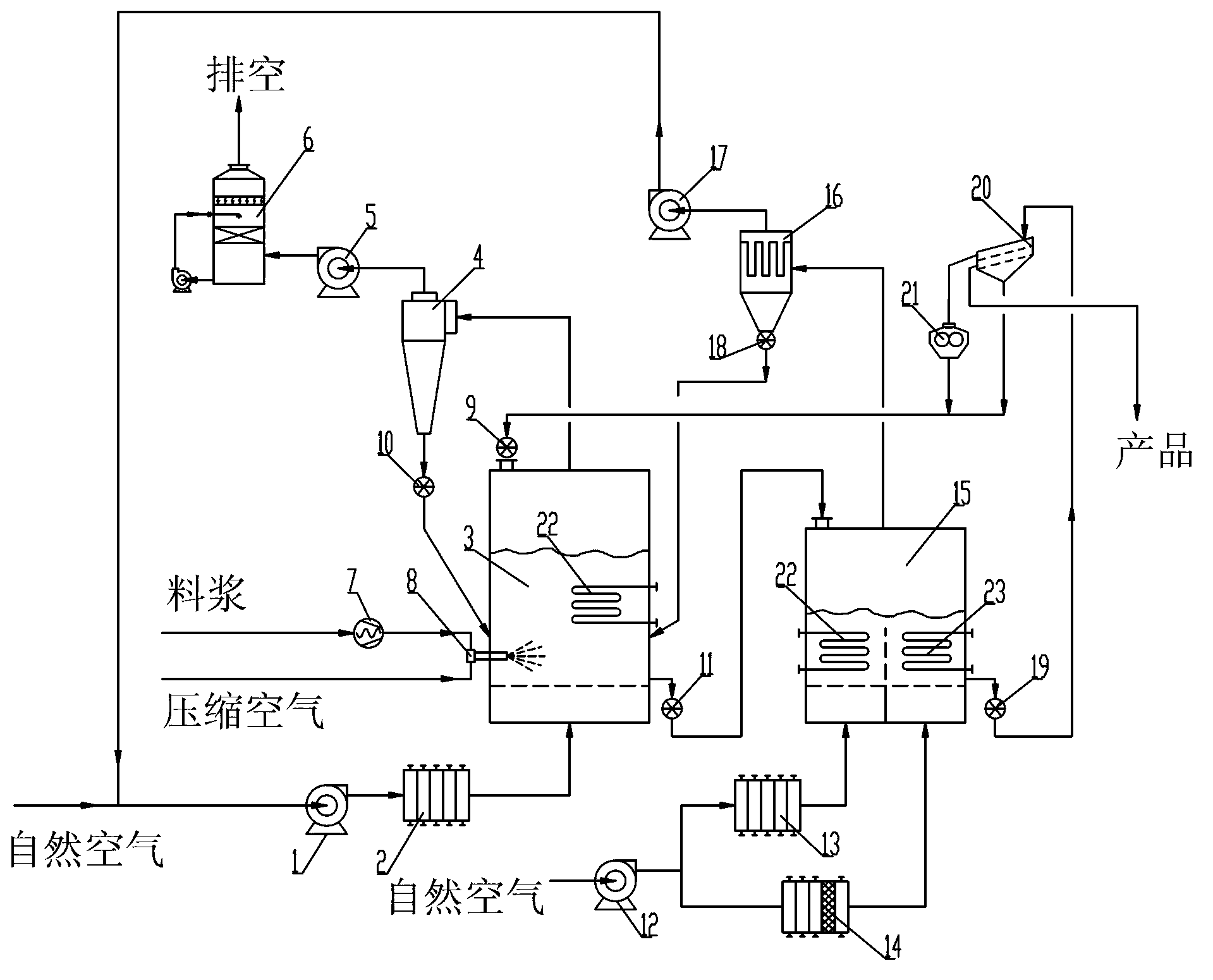

[0025] Refer to the attached figure 1 The fluidized bed low-temperature granulation drying production system of the present invention will be described in detail below.

[0026] The fluidized bed low-temperature granulation drying production system of the present invention comprises a fluidized bed granulator 3, a fluidized bed drying cooler 15, a seed crystal circulation system, a dust recovery system and an air supply and dehumidification system. The first discharge rotary valve 11 of the fluidized bed granulator 3 is connected to the feed port of the fluidized bed drying cooler 15. The fluidized bed granulator 3 is provided with a two-fluid spray gun 8 and a two-fluid spray gun 8 Link to each other with slurry pipeline and compressed air pipeline respectively, described slurry pipeline links to each other with feed pump 7, described seed crystal circulation system includes vibrating screen 20 and crusher 21, described vibrating screen 20 and The crusher 21 is connected, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com