Cracking assistant for improving low-carbon olefin concentration

A catalytic cracking aid and concentration technology, used in cracking, catalytic cracking, molecular sieve catalysts, etc., can solve the problem of weakening the conversion capacity of heavy oil, and achieve improved conversion capacity of heavy oil, high conversion activity of heavy oil, good coke and dry gas selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

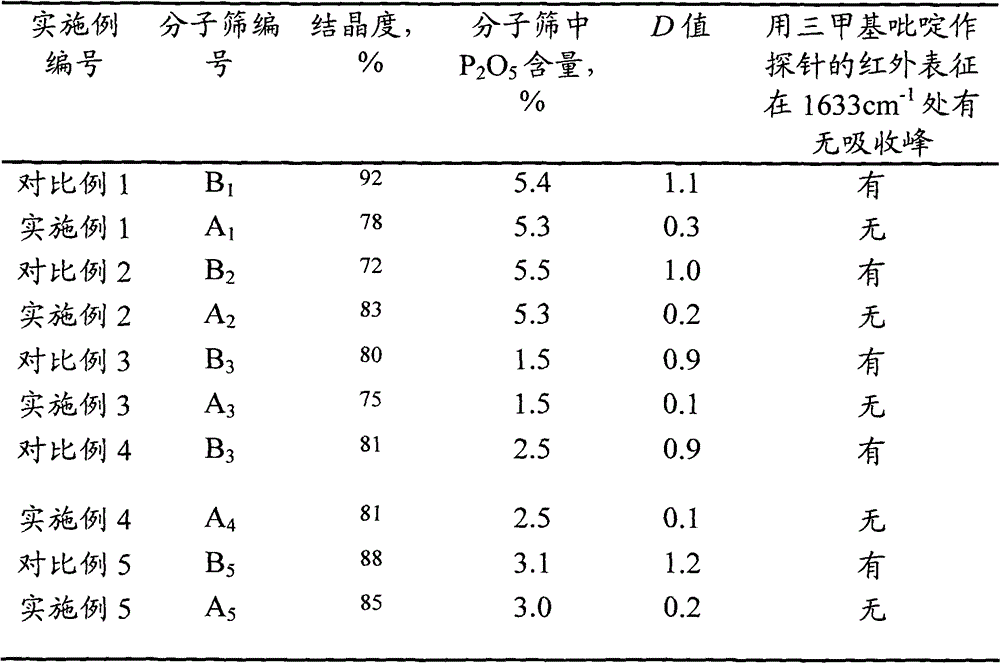

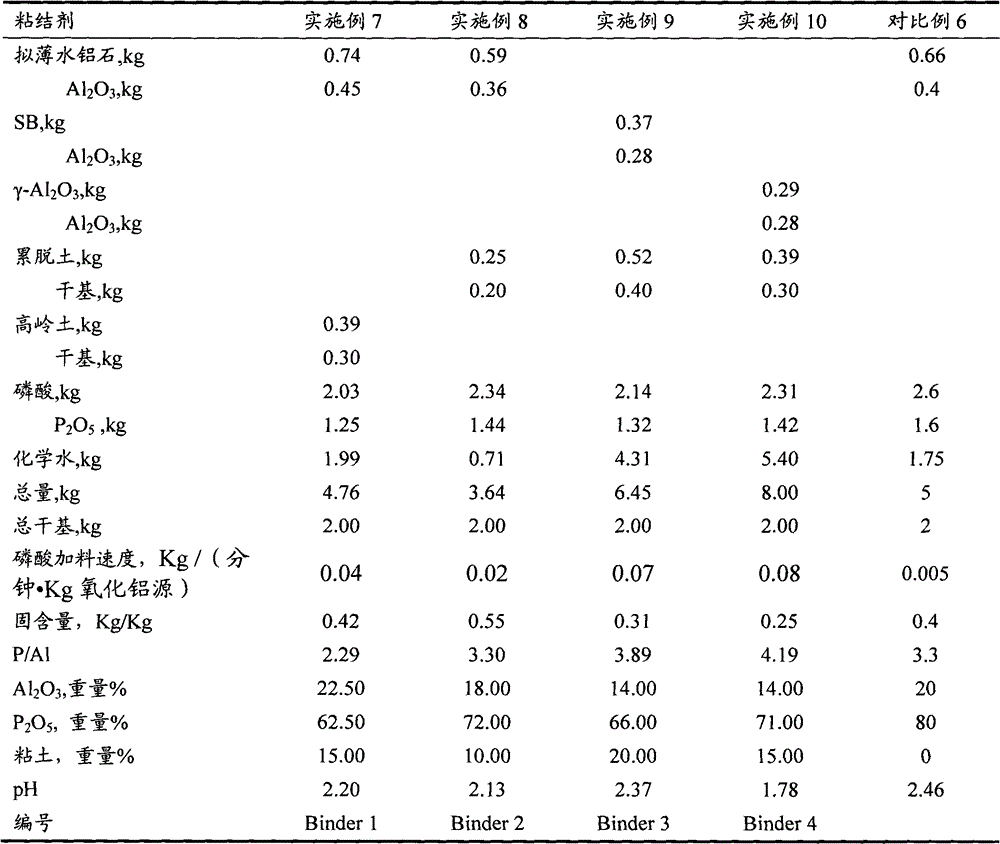

[0032] In the preparation method of the catalytic cracking aid provided by the present invention, the first clay-containing phospho-aluminum inorganic binder, based on its dry basis weight, contains Al 2 O 3 15-40% by weight of aluminum component, as P 2 O 5 45-80% by weight of the phosphorus component and 1-40% by weight of the first clay on a dry basis, with a P / Al weight ratio of 1.0-6.0, a pH of 1.0-3.5, and a binder solid content of 15 ~60% by weight. The preparation method of the first clay-containing phosphorus aluminum compound inorganic binder includes:

[0033] (1) The alumina source, the first clay and water are beaten and dispersed into a slurry with a solid content of 8 to 45% by weight; the alumina source is aluminum hydroxide and / or aluminum oxide that can be peptized by acid. The first clay on dry basis and Al 2 O 3 The calculated weight ratio of the alumina source is 1-40:15-40;

[0034] (2) Under stirring, add concentrated phosphoric acid to the slurry obtained i...

specific Embodiment approach

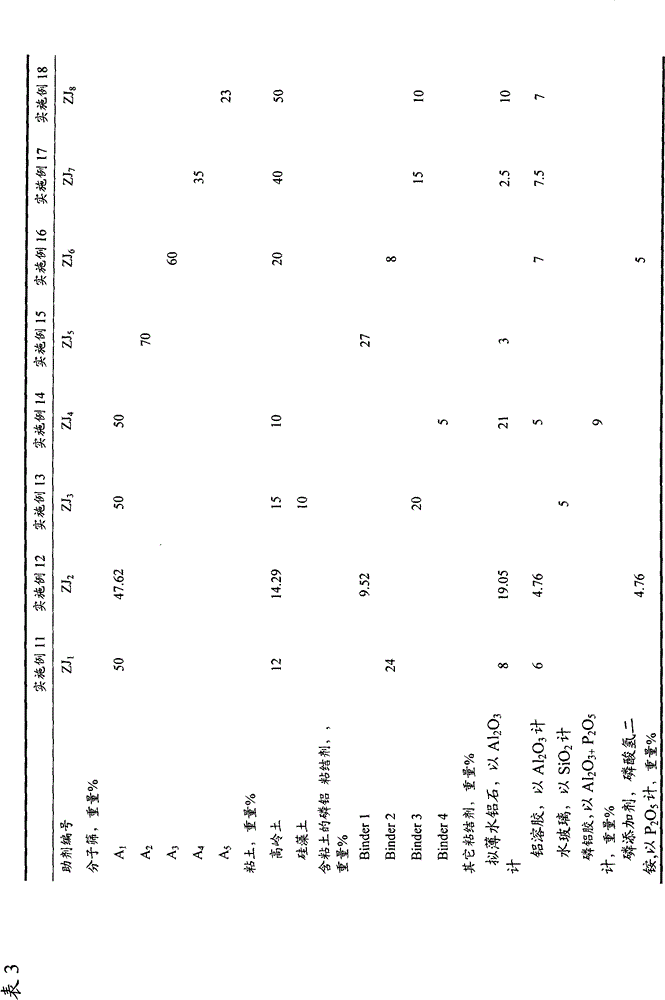

[0045] A specific embodiment of the preparation method provided by the present invention includes:

[0046] (1) According to molecular sieve: ammonium salt: H 2 The weight ratio of O=1:(0.1~1):(5~10), the sodium type molecular sieve with MFI structure is exchanged at room temperature to 100℃ for 0.3~1 hour, then filtered and dried;

[0047] (2) The ammonium-exchanged molecular sieve is impregnated and modified with a phosphorus-containing compound solution and a solution containing a transition metal compound, and then dried and calcined; the calcining temperature is 400-800°C; The metal compound solution impregnating the molecular sieve after the ammonium exchange may be impregnated with a solution containing both a phosphorus compound and a transition metal compound, or may be impregnated with a solution containing a phosphorus compound and a solution containing a transition metal compound respectively; It can be carried out one or more times, preferably, impregnation is carried ...

Embodiment 1

[0061] Put 5kg NH 4 Cl is dissolved in 100kg water, and 10kg (dry basis) crystallized product ZSM-5 molecular sieve (produced by Qilu Branch of Sinopec Catalysts, synthesized by amine method, SiO 2 / Al 2 O 3 =50), after exchange at 90℃ for 0.5h, filter cake to be obtained; remove 0.9kg H 3 PO 4 (Concentration 85% by weight) and 0.81kgFe(NO 3 ) 3 ·9H 2 O was dissolved in 9kg of water, the impregnating solution was mixed with the filter cake, soaked, dried, and roasted at 550°C for 2 hours; 1kg of the above roasted molecular sieve was taken and mixed with 0.536kg of ethyl orthosilicate (Beijing Chemical Reagent Company, Analytical purity, SiO 2 The content is 28% by weight), 0.333kg of tetrapropylammonium bromide (produced by Guangzhou Dayou Fine Chemical Factory, analytically pure, 99%) and 1.2L of water are mixed, and placed in a crystallization kettle with polytetrafluoroethylene lining. After being statically crystallized at 150°C for 20 hours and then cooled to room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com