Method for synthesizing sphere-like nano yttrium and cerium doped zirconia according to ethylene glycol sol-gel method

A glycol-like spherical technology, applied in the field of materials, can solve the problems of limiting the application of zirconia, and achieve the effect of cheap raw materials and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

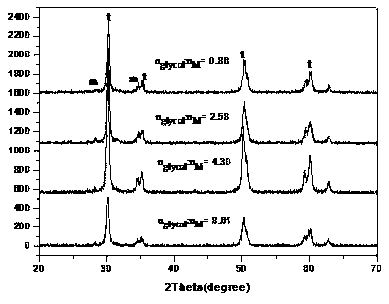

[0019] Add 0.625ml of 1mol / L yttrium nitrate solution, 0.521ml of 0.4mol / L cerous nitrate solution, 6.7848g of zirconium nitrate, 24ml of deionized water, and 1ml of ethylene glycol (the mixture of ethylene glycol and metal ions) into a round bottom flask. The ratio of the amount of substances is 0.86), and the zirconium nitrate is completely dissolved into a transparent solution under magnetic stirring. Place the round-bottomed flask in an oil bath, connect the reflux tube, heat to 130°C, and reflux for 8 hours to form a sol. The obtained sol was transferred to an oven and dried at 110° C. for 12 h to obtain a solid gel. Then placed in a muffle furnace and calcined at 800°C for 3h. A partially stabilized zirconia (PSZ) powder was obtained.

[0020] According to the same method as above, only the amount of ethylene glycol added is different, which are 3ml, 5ml and 10ml respectively, and the corresponding ratios of the amount of ethylene glycol to metal ions are 2.58, 4.30 an...

Embodiment 2

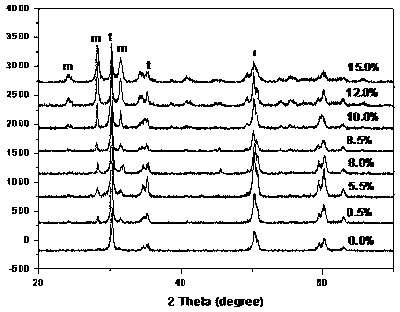

[0022] Add 0.625ml of 1mol / L yttrium nitrate solution, 0.521ml of 0.4mol / L cerous nitrate solution, 6.7848g of zirconium nitrate, 24ml of deionized water, and 1ml of ethylene glycol (the mixture of ethylene glycol and metal ions) into a round bottom flask. The ratio of the amount of substances is 0.86), adding NaCl solid, the ratio of its mass to the mass of NaCl and the total mass of nitrate is 0.5%, and all the zirconium nitrate is dissolved into a transparent solution under magnetic stirring. Place the round-bottomed flask in an oil bath, connect the reflux tube, heat to 130°C, and reflux for 8 hours to form a sol. The obtained sol was transferred to an oven and dried at 110° C. for 12 h to obtain a solid gel. The obtained solid gel was firstly washed with water and ethanol to remove the sodium chloride therein, and then placed in a muffle furnace for calcination at 800° C. for 3 h. A partially stabilized zirconia (PSZ) powder was obtained.

[0023] According to the same ...

Embodiment 3

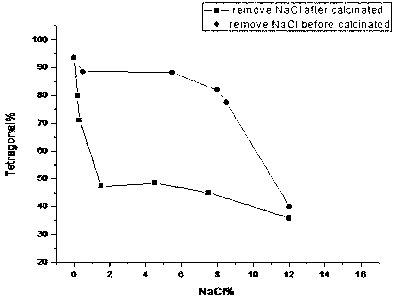

[0025] According to the basic method of Example 2, the added amount of sodium chloride was changed, respectively 0.2%, 0.3%, 1.5%, 4.5%, 7.5%, 12%, and the obtained solid gel was not washed out with water and ethanol. Sodium chloride is directly put into the muffle furnace for calcination. Measure the XRD patterns of the obtained powders respectively, and the relationship diagram between the tetragonal phase content and the amount of sodium chloride added is shown in image 3 , compared with the sample that was calcined after washing off sodium chloride in Example 2, the tetragonal phase content decreased significantly. The SEM image of the synthesized sample is shown in Figure 6, which shows that the addition of sodium chloride can significantly improve the dispersibility and particle sphericity of the synthesized product, but the addition amount should not be too much. When it exceeds 7.5%, the particle agglomeration is serious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com