Method for treating erythromycin thiocyanate wastewater

A treatment method and wastewater technology, applied in natural water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of high treatment cost and incomplete treatment of pollutants, and achieve a high degree of automation , good removal effect, good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

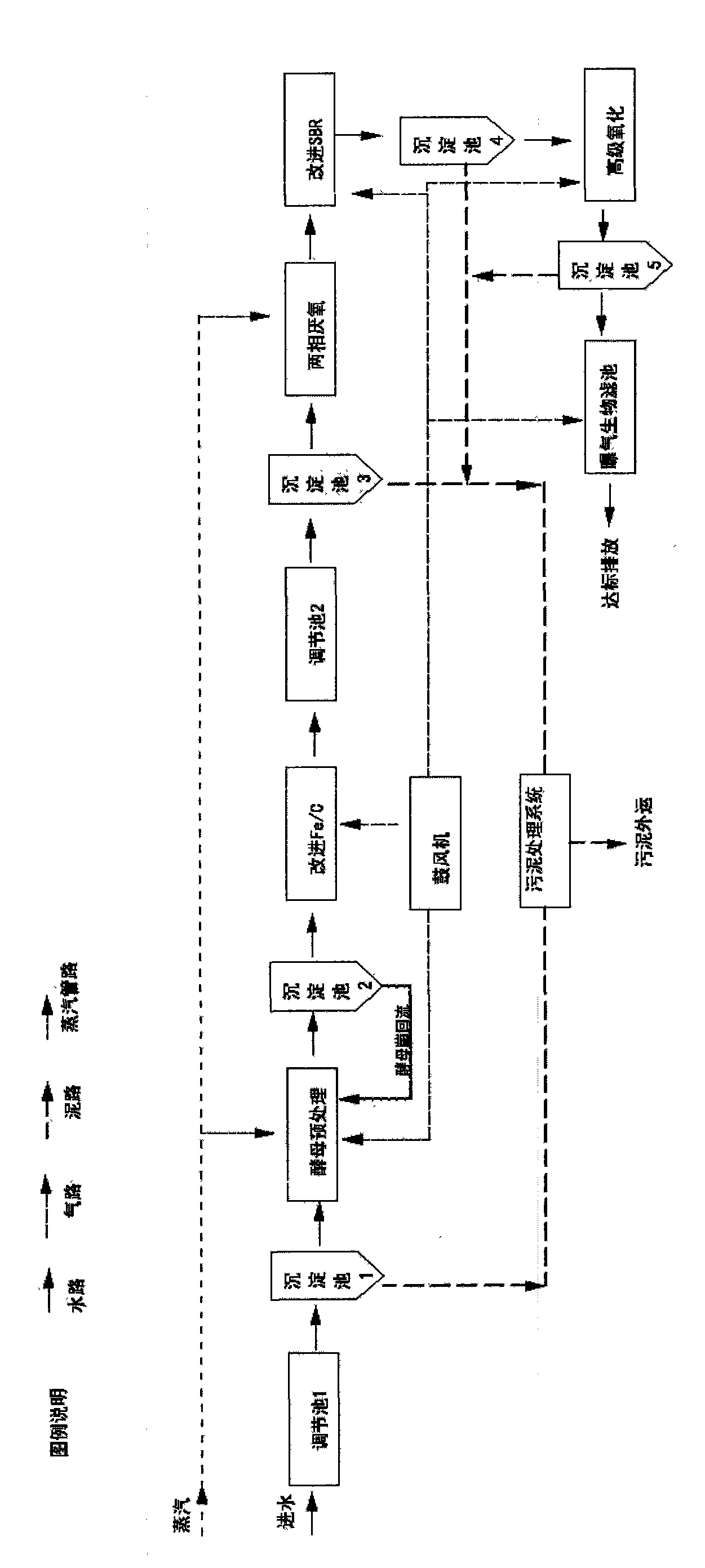

Image

Examples

Embodiment 1

[0029]Embodiment 1 adopts the erythromycin thiocyanate industrial waste water that the waste water treatment method of the present invention handles

[0030] A biopharmaceutical Co., Ltd. produces 1,000 tons of erythromycin thiocyanate annually, and the total amount of sewage generated every day is 6,000 cubic meters. Fermentation process wastewater, extraction process wastewater, salt-forming process wastewater, purification process wastewater, etc. enter the adjustment tank 1 and mix COD and NH 3 -N, SCN - , SO 4 2- They are 40000mg / L, 1000mg / L, 1800mg / L, 800mg / L respectively. Add polyferric sulfate at a ratio of 2‰ to settle for 3 hours. After this step, the COD removal rate is 10-15%, and the precipitate is discharged through the sedimentation tank 1. At the same time, add hydrochloric acid to adjust the pH value of wastewater to about 3; in the yeast treatment system, maintain the temperature at 32°C and add high-efficiency yeast at a ratio of 4‰. After 48 hours of re...

Embodiment 2

[0035] Embodiment 2 adopts wastewater treatment method of the present invention to process erythromycin thiocyanate process wastewater

[0036] A biopharmaceutical Co., Ltd. produces 1,000 tons of erythromycin thiocyanate annually, and the total amount of sewage generated every day is 6,000 cubic meters. Fermentation process wastewater, extraction process wastewater, salt-forming process wastewater, purification process wastewater, etc. enter the adjustment tank 1 and mix COD and NH 3 -N, SCN - , SO 4 2- They are 45000mg / L, 1300mg / L, 2000mg / L, 1000mg / L respectively. Add polyferric sulfate at a ratio of 2.5‰ and settle for 3 hours. After this step, the COD removal rate is 13-17%, and the precipitate is discharged through the sedimentation tank 1. At the same time, hydrochloric acid is added to adjust the pH value of the wastewater to about 3; in the yeast treatment system, the temperature is maintained at 32°C and the high-efficiency yeast is added at a ratio of 3.5‰. After...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com