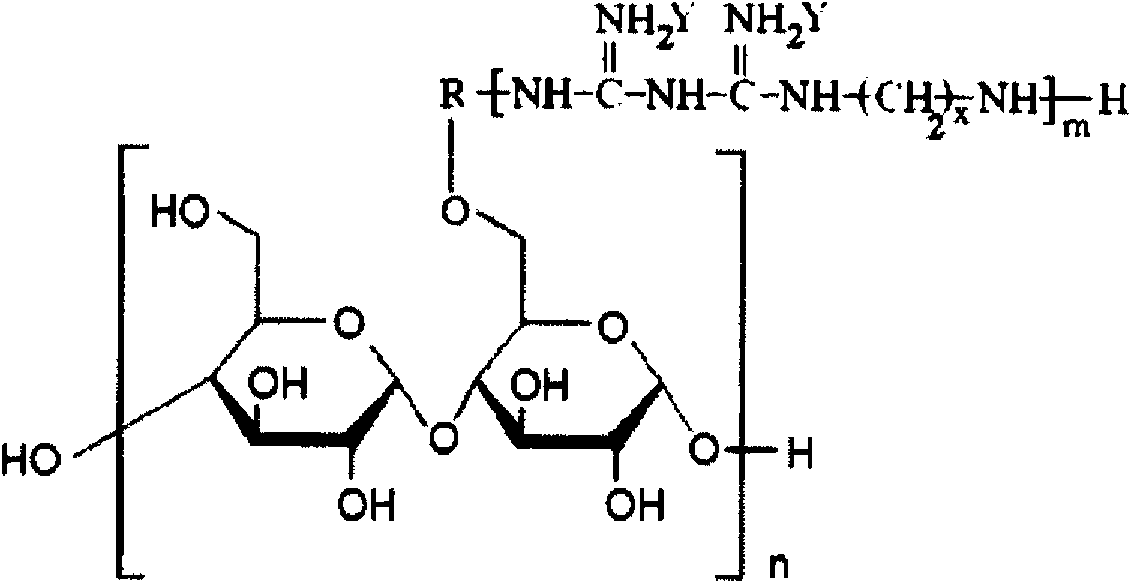

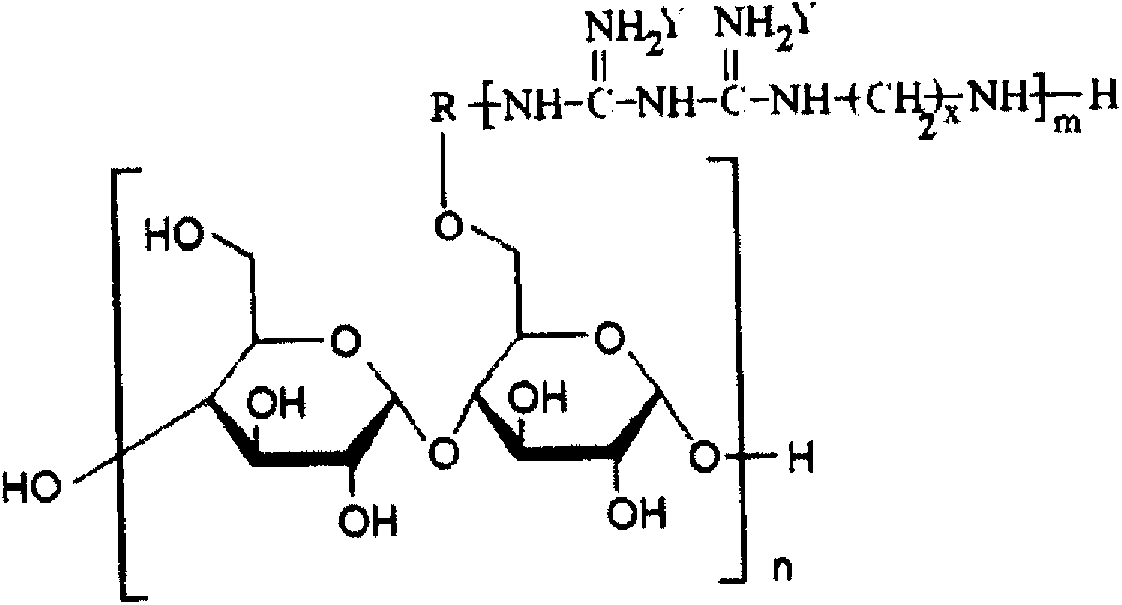

Modified starch for grafting guazatine oligomer as well as preparation method and application of modified starch

A biguanide salt and oligomer technology is applied in the field of starch modification and processing, which can solve the problems of poor compatibility between guanidine salt antibacterial agent and polymer matrix, difficult and durable antibacterial effect, and limited application, and achieve high-efficiency broad-spectrum antibacterial Anti-mildew properties, improved antimicrobial properties, high density effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

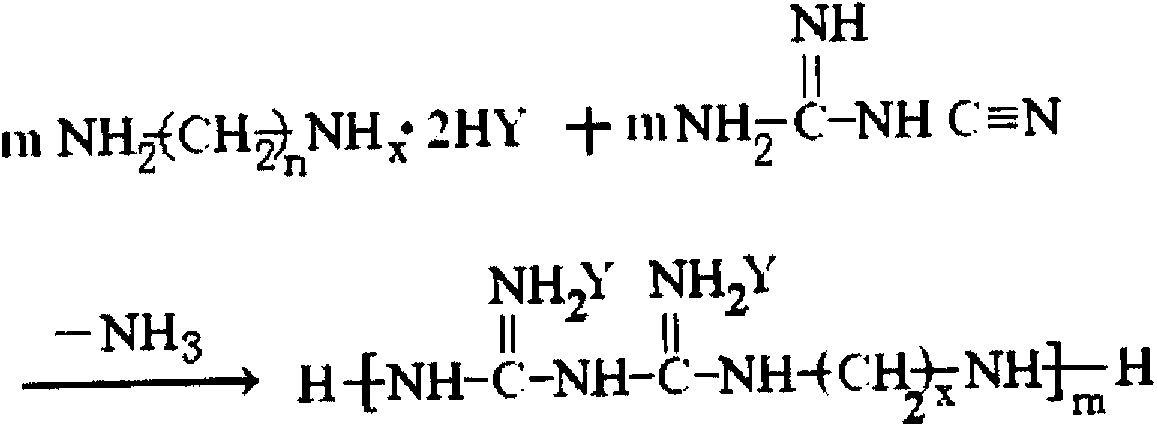

[0037] Preparation of polybutylene diamine carbonate biguanide:

[0038]Take 88g of 1,10-decanediamine, make it into a 40%wt aqueous solution, put it into a 1000ml three-neck bottle, pass in carbon dioxide until the pH value reaches 3, and then distill under reduced pressure to remove water. Under nitrogen protection, add 84g of dicyandiamide, stir and heat up to 90°C, react for 40 minutes, then heat up to 125°C for 6 hours, stop heating; after cooling, biguanide oligomer of butanediamine carbonate is obtained. Its molecular weight is about 800, and the product has high-efficiency antibacterial properties, and its minimum inhibitory concentration is 5.5ppm.

Embodiment 2

[0040] Preparation of polytriethylenetetramine hydrochloride biguanide:

[0041] Take 73g of triethylenetetramine, add it to a 250ml three-necked bottle, add 35.5% hydrochloric acid dropwise to pH = 2, then distill off water under reduced pressure; add 43g of dicyandiamide to the system, stir and raise the temperature under the protection of nitrogen To 110°C, react for 2 hours, then raise the temperature to 180°C, react for 8 hours, stop heating; after cooling, triethylenetetramine hydrochloride biguanide oligomer is obtained. Its molecular weight is about 2500, and the product has high-efficiency antibacterial properties, and its minimum inhibitory concentration is 1.5ppm.

Embodiment 3

[0043] Preparation of polyhexamethylenediamine phosphate biguanide:

[0044] Get 116g of hexamethylenediamine, add it to a 500ml three-necked bottle, add 20% phosphoric acid dropwise to pH=2.5, then distill off the water under reduced pressure; add 85g of dicyandiamide to the system, stir and heat up to React at 150°C for 2 hours, then raise the temperature to 200°C and react for 6 hours, then stop heating; after cooling, hexamethylenediamine phosphate biguanide oligomer is obtained. Its molecular weight is about 1500, and the product has high-efficiency antibacterial properties, and its minimum inhibitory concentration is 9.0ppm.

[0045] Below are the preparation examples of the modified starch of several grafted biguanide oligomers:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com