Preparation method of cationic polyacrylamide water-in-water emulsion

A technology of polyacrylamide and water-in-water emulsion, which is applied in the field of water-soluble polymer synthesis, can solve the problems of slow adsorption rate of dispersant, low positive charge density, poor stabilization effect, etc., and achieves good fluidity and low positive charge density. , the effect of reducing the positive charge density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

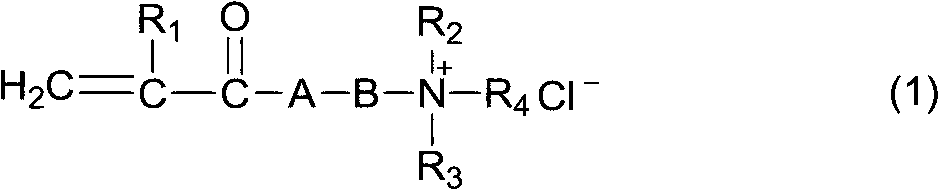

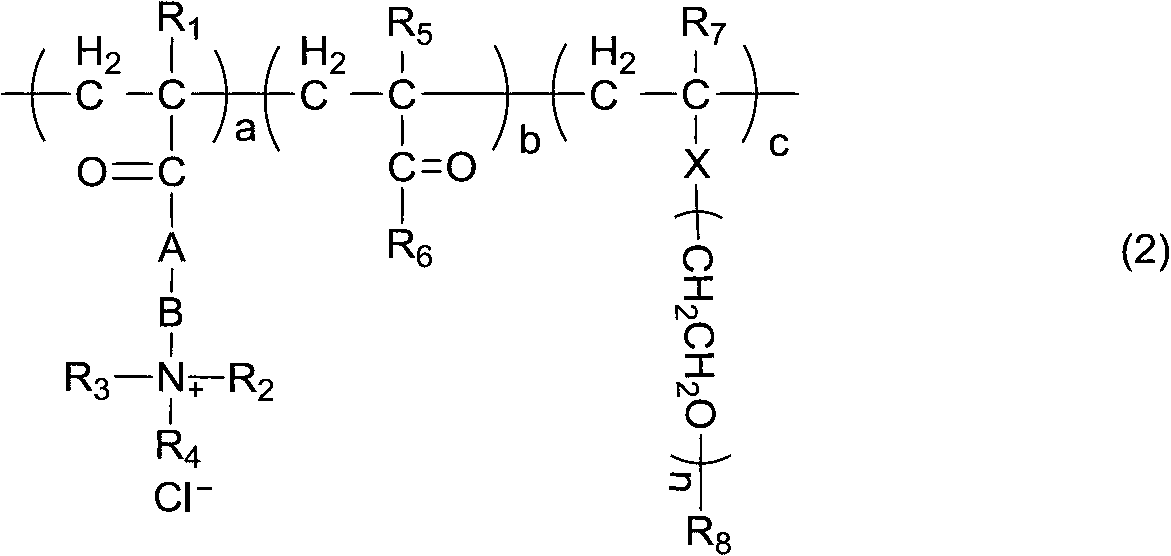

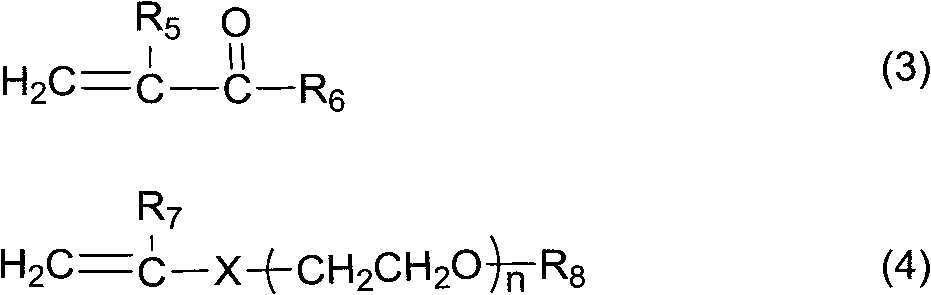

Method used

Image

Examples

Embodiment 1

[0052] Dispersant Synthesis Example 1 (Synthesis of Dispersant D-1)

[0053] In a glass reactor equipped with a thermometer, a stirrer, a dropping funnel, a nitrogen inlet tube and a reflux condenser, add 18.2 g (F-1), 0.15 g of hydrogen peroxide, and 100 ml of deionized water, and blow with nitrogen while stirring. Sweep the reaction vessel, raise the temperature to 45°C, then mix 9.68 grams of (B-1) and 7.2 grams of (E-1) and 80 ml of water to make a mixed monomer aqueous solution, drop it into the reactor, and the dropping time is 2 Hours, and at the same time dropwise add 20 grams of 1% ascorbic acid solution, the dropping time is 2 hours, after the dropping is completed, keep warm for 3 hours and cool to room temperature to obtain dispersant D-1, and then use the above-mentioned aqueous gel permeation chromatography (GPC) Measurement was carried out, and the measurement result showed that its molecular weight was 17,000.

[0054] Dispersant Synthesis Example 2-4 (Synthes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com