Extraction method for antioxidant polypeptide in Guangchang nymphaea alba

An antioxidant polypeptide and extraction method technology, applied in the field of antioxidant polypeptide extraction, can solve problems such as complex biosafety purification process, and achieve the effects of strong antioxidant capacity, simple process, and controllable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

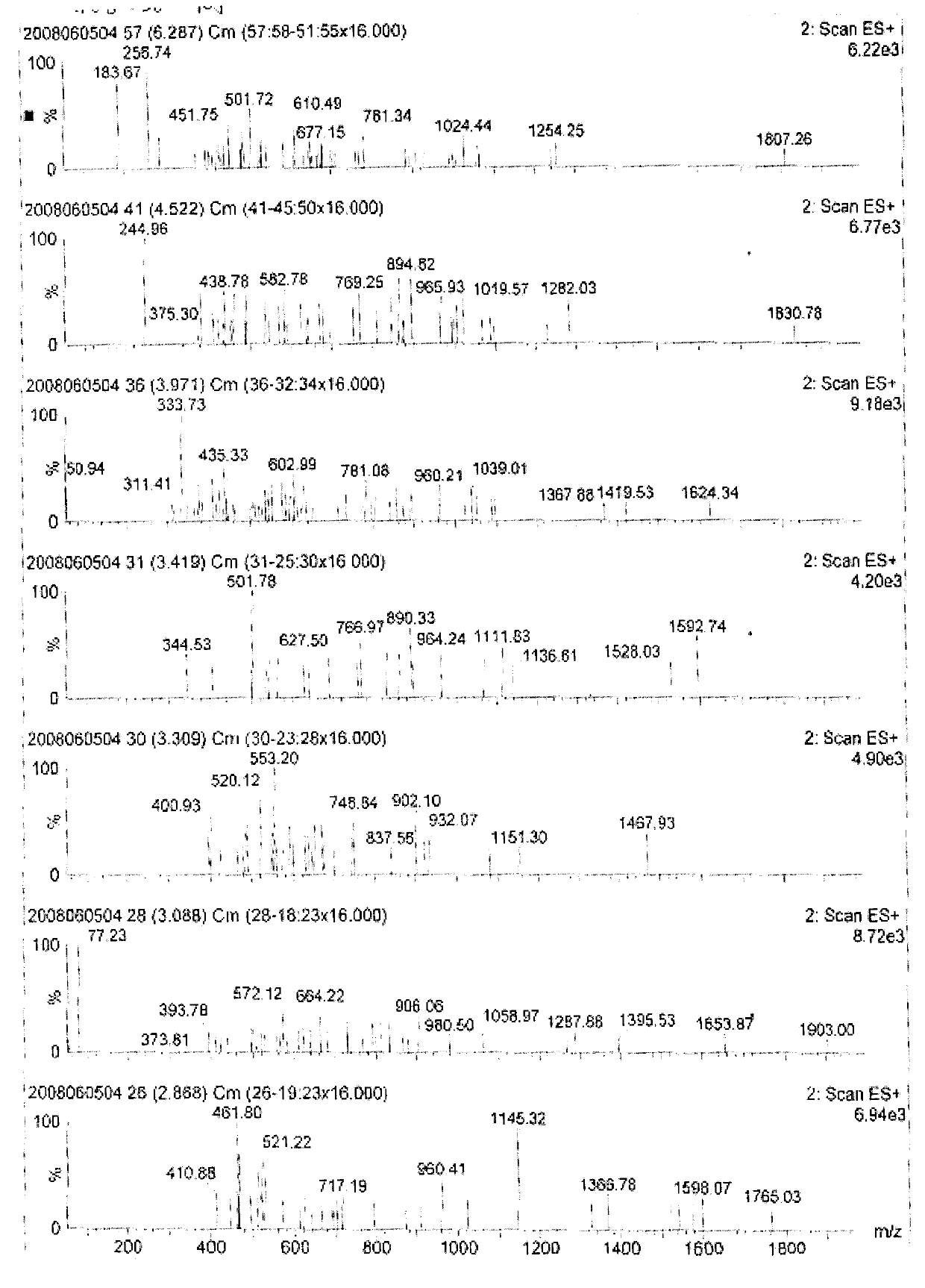

Image

Examples

Embodiment 1

[0015] The protein extraction of Guangchang white lotus adopts the following steps.

[0016] (1) Grind the white lotus into powder with a mixing machine, sieve out about 99% of the fine powder with a single layer of gauze, and sift out about 85% of the fine powder with a double layer of gauze. Put the white lotus powder into water at 60°C, the water contains about 3% hydrogen peroxide, and the ratio of white lotus powder to water is 1:12.

[0017] (2) Add sodium hydroxide aqueous solution, and keep stirring until the pH value is 8-9, let it stand for 30 minutes, remove the oily and milky substances, and separate the solid and liquid to obtain solid and liquid substances.

[0018] (3) Mix and stir the solid and water in step (2) at a ratio of about 5:1, and separate the water according to step (2), mix the water with the liquid in (2), and wash with hydrochloric acid The pH was adjusted to about 4.5, and the protein solids were precipitated. Centrifuge for 15 minutes to obtai...

Embodiment 2

[0021] Weigh 15g of Guangchang white lotus protein and prepare it into an aqueous solution with a substrate concentration of 5%. After dissolving, the solution is quickly heated to 85°C and kept at a constant temperature for 15min. After pretreatment, add phosphate buffer to adjust the pH to 8.5, add trypsin, enzymolysis temperature is 45°C, enzyme dosage is 9% of the substrate concentration, after enzymolysis for 120min, the enzymolysis solution is rapidly heated to 90°C, Keep it for 20min, and carry out the enzyme-inactivating treatment. Then rapidly cool to room temperature, centrifuge at 3000r / min for 20min, and take the supernatant. At this time, the degree of hydrolysis of white lotus protein is 37.25%. According to the ratio of 100 grams: 100ml, trypsin hydrolyzate was added to the wet macroporous adsorption resin DA201-C, kept on a constant temperature shaker at 25°C for 180min, the rotation speed was 150r / min, and eluted with 75% ethanol solution for 120min, collected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com