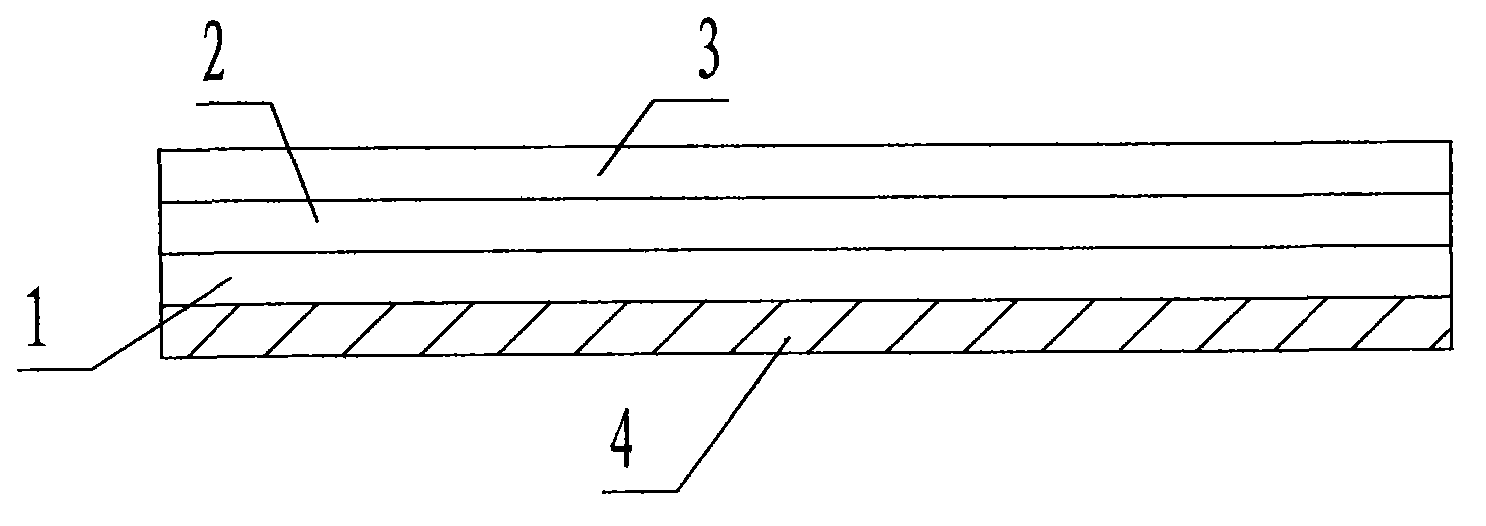

Photovoltaic cell with three layers of antireflective films in composite structures and composite coating method thereof

A technology of anti-reflection film and photovoltaic cell, which is applied in the direction of circuits, electrical components, sustainable manufacturing/processing, etc. It can solve the problems of narrow anti-reflection spectrum bandwidth, difficulty in improving photoelectric conversion efficiency of solar photovoltaic cells, and difficulty in improving photoelectric conversion efficiency. , to achieve the effect of expanding the anti-reflection spectral bandwidth, improving the photoelectric conversion efficiency, and overcoming the narrow anti-reflection spectral bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] conditions, equipment

[0044] Ambient air pressure: one atmosphere;

[0045] Ambient temperature: room temperature;

[0046] Preparation equipment: PECVD deposition furnace;

[0047] Process flow: into the furnace, nitrogen filling, vacuuming, pre-deposition, vacuuming, coating the first layer of film, coating the second layer of film, coating the third layer of film;

[0048] Step 1, into the furnace;

[0049] Insert the silicon wafer 4 after surface texturing, diffusion junction, dephosphorous silicon glass, and plasma etching into the graphite boat, then put the graphite boat together with the silicon wafer 4 into the PECVD deposition furnace, and close the furnace door;

[0050] Step 2, Nitrogen filling;

[0051] Open the nitrogen valve and exhaust valve of the PECVD furnace, feed nitrogen into the PECVD furnace, and replace and remove the air in the PECVD furnace by nitrogen, so that the PECVD furnace is in a nitrogen atmosphere; after that, close the exhaust va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com