Carbon nanotube paper and making method thereof

A technology of carbon nanotube paper and carbon nanotubes, which is applied in the direction of nanocarbon, nanotechnology, nanotechnology, etc., can solve the problems of restricting the wide application of carbon nanotube paper, destroying the structure and shape of carbon nanotubes, and reducing the performance of carbon nanotube paper and other issues, to achieve the effect of easy implementation, enhanced electrical conductivity performance, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

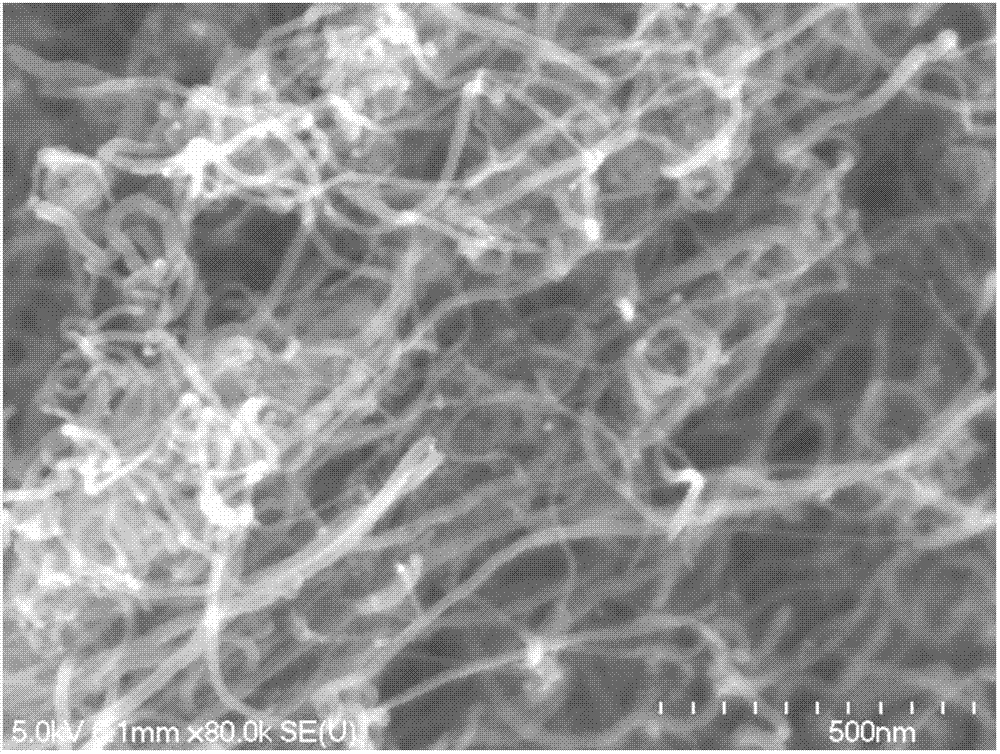

[0027] Take by weighing 1g multi-walled carbon nanotubes, pour into 1000ml TritonX-100 (polyethylene glycol octyl phenyl ether) containing 20% (weight), molecular formula is (C 2 h 4 O) n C 14 h 22 O) In the aqueous solution of the active agent, use ultrasonic vibration and stir for 1 hour to disperse the carbon nanotubes uniformly to form a carbon nanotube suspension. The uniformly dispersed carbon nanotube suspension is filtered through a magnetic filter to obtain a filter cake with certain impurities. Wash the filter cake with ethanol solution (alcohol containing water) to remove the active agent remaining on the surface of the filter cake, and obtain a filter cake without impurities. Finally, the impurity-free filter cake is passed into an oven filled with argon, and continuously heated at 200°C for 5 hours to obtain carbon nanotubes that do not contain impurities, the structure and shape of carbon nanotubes are not damaged, and the carbon nanotubes are evenly arrang...

Embodiment 2

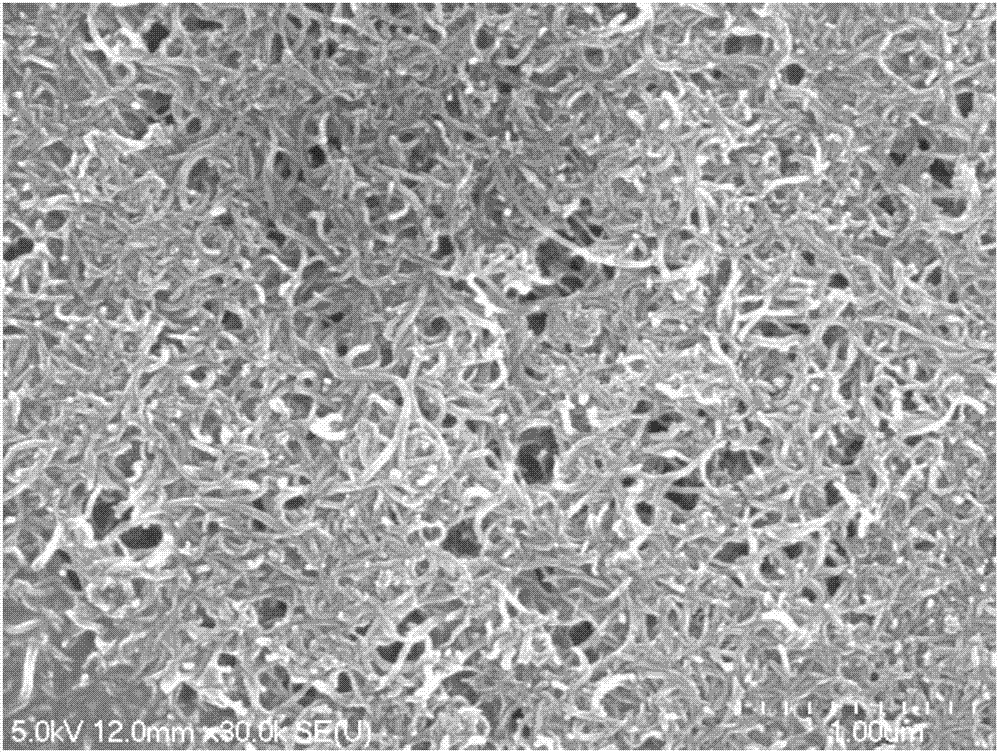

[0030] Weigh 0.1g of single-walled carbon nanotubes and pour into 1000ml of cetyltrimethylammonium bromide containing 30% (weight) (structural formula is C 16 h 33 (CH 3 ) 3 NBr) in an aqueous solution of the active agent, using ultrasonic vibration and stirring for 2 hours to disperse the carbon nanotubes uniformly to form a carbon nanotube suspension. The uniformly dispersed carbon nanotube suspension is filtered through a magnetic filter to obtain a filter cake with certain impurities. Wash the filter cake with isopropanol (molecular formula (CH 3 ) 2 CHOH) aqueous solution to remove the active agent remaining on the surface of the filter cake to obtain a filter cake without impurities. Finally, the impurity-free filter cake is passed into an oven filled with argon, and continuously heated at 200°C for 5 hours, so as to obtain carbon nanotubes without impurities, with the structure and shape of carbon nanotubes undamaged and uniformly arranged. nanotube paper.

[003...

Embodiment 3

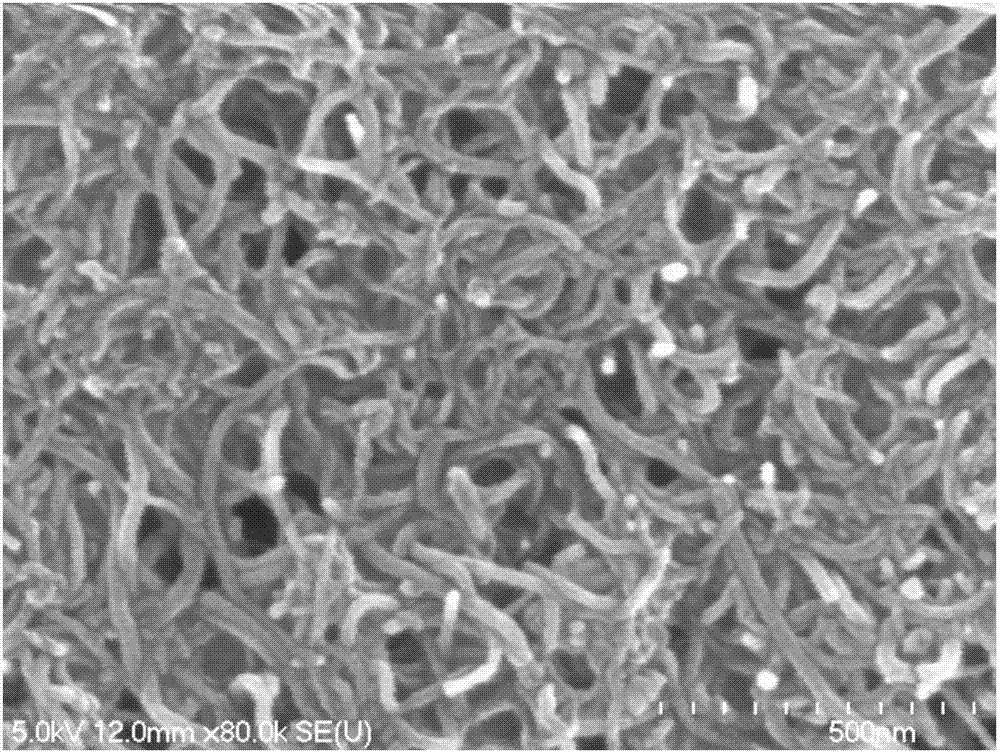

[0033] Weigh 0.5g of multi-walled carbon nanotubes and pour into 1000ml of Tween-80 (polyoxyethylene sorbitan monooleate, molecular formula C) containing 40% (weight). 12 h 10 ClNO 3 ) in the active agent aqueous solution, using ultrasonic vibration and stirring for 3 hours, so that the carbon nanotubes are uniformly dispersed to form a carbon nanotube suspension. The uniformly dispersed carbon nanotube suspension is filtered through a magnetic filter to obtain a filter cake with certain impurities. Filter cake with acetylated acetone (structural formula is CH 3 COCH 2 COCH 3 ) by washing with an aqueous solution to remove the active agent remaining on the surface of the filter cake to obtain a filter cake without impurities. Finally, the impurity-free filter cake is passed into an oven filled with argon, and continuously heated at 400°C for 5 hours, so as to obtain carbon nanotubes that do not contain impurities, the structure and shape of carbon nanotubes are not damage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com