Preparation method of powdered drag reducing agent for crude oil transportation

A drag reducer, powder technology, applied in mechanical equipment, gas/liquid distribution and storage, pipeline systems, etc., can solve the problems of high processing cost, intolerant of shear, easy to coagulate and glue, and achieve low production cost , Improve performance and consume less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

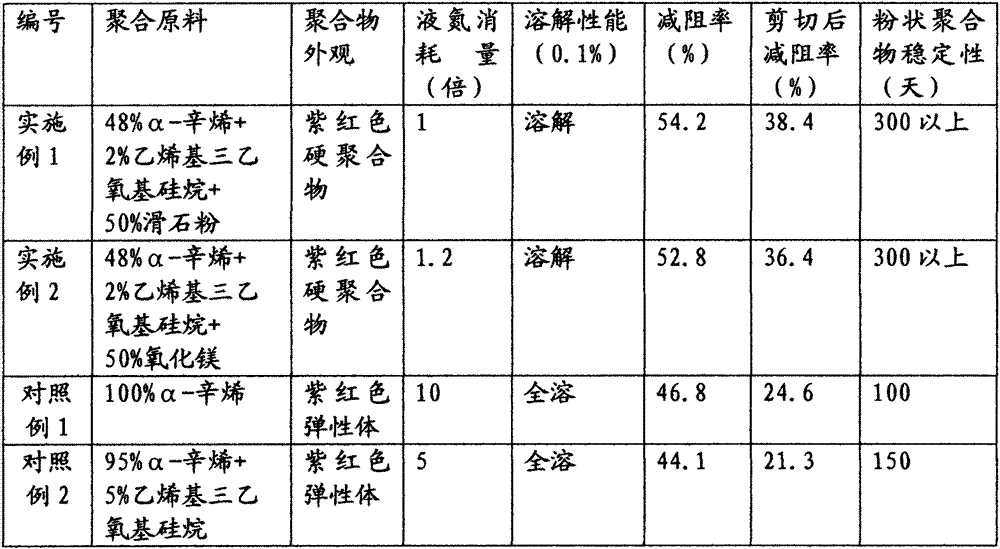

Embodiment 1

[0031] 10.0 g of polymer grade TiCl 3 Add 100ml of freshly distilled hexane solvent to make a main catalyst suspension; add 50ml of diethylaluminum chloride to 150ml of freshly distilled hexane solvent to make a cocatalyst solution.

[0032]Add a total of 500g of 48% by weight α-octene and 2% vinyltriethoxysilane in the polymerization bottle as the polymerization raw material, then add 500g of talcum powder after burning treatment, mix well, and freeze in the freezer to below -5°C. Take the titanium trichloride catalyst and the diethylaluminum monochloride co-catalyst with a syringe, make them mix and activate for 30 seconds, add them into the polymerization bottle, and shake well. The weight ratio of the catalyst added is α-olefin:titanium trichloride:diethylaluminum chloride=1500:1:3. When the mixture is pre-polymerized until the viscosity of the reaction solution reaches the point where the catalyst and the powder no longer sink, it is left to react at -10°C-15°C for 24 h...

Embodiment 2

[0034] Add a total of 500g of 48% by weight α-octene and 2% vinyltriethoxysilane in the polymerization bottle as the polymerization raw material, then add 500g of magnesium oxide through burning treatment, mix well, and do the same according to Example 1 Experiments were carried out under the process conditions, and the experimental evaluation results of drag-reducing polymers are shown in Table 1. Low-temperature crushing of drag-reducing polymer consumes about 1.2 times the weight of liquid nitrogen refrigerant, 10×10 in 0# diesel -6 The drag reduction rate under the concentration is 52.8%, and the drag reduction rate after shearing is 36.4%. The powder drag reducer is stable for more than 300 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com