Carbon dioxide-based poly (carbonic ester-ether) polyurethane and preparation method thereof

A carbon dioxide and carbonate technology, applied in the field of polymers, can solve the problems of limited mechanical properties of materials, weak interaction force, poor mechanical properties such as material strength and toughness, etc., to achieve excellent mechanical properties and improve hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

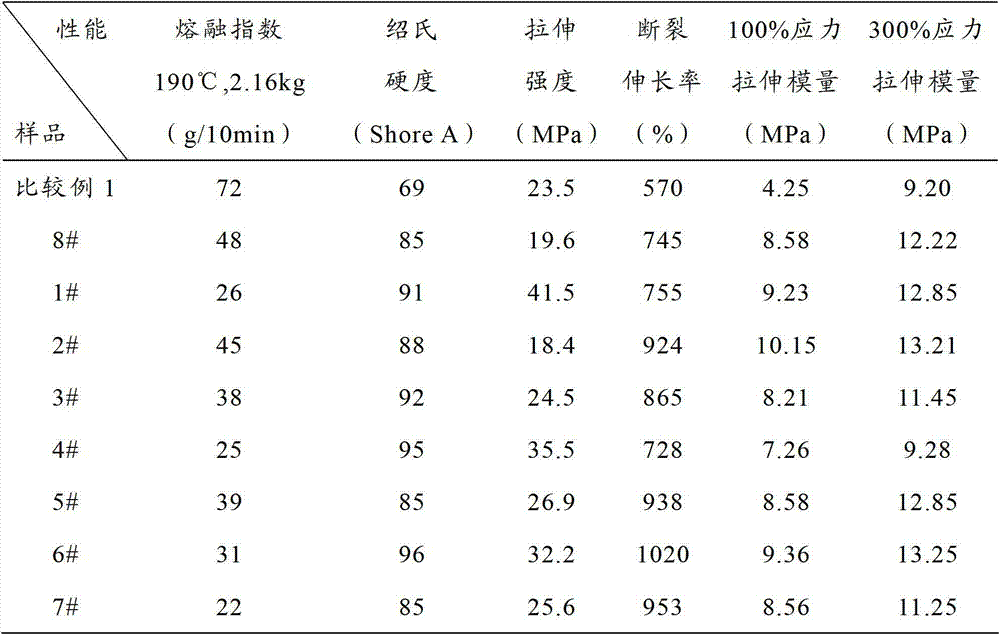

Examples

preparation example Construction

[0061] The present invention also provides a method for preparing carbon dioxide-based poly(carbonate-ether) polyurethane, comprising the following steps:

[0062] heating and melting the first component of 30mol% to 90mol% and the second component of 10mol% to 70mol% to obtain a molten mixture; the first component is carbon dioxide-based poly(carbonate-ether) polyol, the The number average molecular weight of the first component is 500~5000; the second component is polyaromatic dicarboxylic acid-aliphatic glycol ester or polyaromatic dicarboxylic acid-aliphatic dicarboxylic acid- Aliphatic glycol ester, the number average molecular weight of the second component is 500-5000, and the melting point of the second component is less than 160°C;

[0063] The molten mixture is reacted with an isocyanate to obtain a carbon dioxide-based poly(carbonate-ether) polyurethane.

[0064] The present invention combines carbon dioxide-based poly(carbonate-ether) polyol with polyaromatic dica...

Embodiment 1

[0075] 20mL containing 1.38g K 3 Co (CN) 6 K 3 Co (CN) 6 Slowly add deionized aqueous solution to 60mL dissolved in 16.3gZnCl 2 ZnCl 2 In the mixed solution of deionized aqueous solution and 30mL tert-butanol (tert-BuOH), after the dropwise addition is completed, the temperature is 50°C, and the reaction is continued with stirring. After 1 hour of reaction, the reaction mixture is obtained;

[0076] The reaction mixture was centrifuged at a speed of 5000r / min with a centrifuge, and after centrifugation for 30min, the precipitate was collected and then washed with 60mL tert-BuOH aqueous solution (V tert-BuOH / V 水 =1) The precipitate was washed with pulp, centrifuged after washing for 30 minutes, the precipitate was collected again, and then washed with 60 mL of tert-butanolized pulp, and finally vacuum-dried to constant weight at a temperature of 50 ° C to obtain Co-Zn bimetallic Cyanide, spare.

Embodiment 2

[0078] Add 3200g of ethylene oxide, 5g of Co-Zn double metal cyanide prepared in Example 1, and 150mL of fully dried dipropylene glycol to the dry polymerization reactor under the protection of argon. After stirring for 1 hour, add carbon dioxide to the reaction The pressure of the kettle reached 7MPa, and the temperature was raised to 70°C for reaction. After 5 hours of reaction, a reaction mixture was obtained. After precipitation, separation and drying, a copolymer carbon dioxide-based poly(carbonate-ether) polyol was obtained.

[0079] Using gel permeation chromatography (GPC) analysis, the results show that the number average molecular weight of the copolymer is 500; using titration analysis, the results show that the hydroxyl value of the copolymer is 221.4; using proton nuclear magnetic resonance analysis, the analysis results 1 H-NMR: 4.40ppm (2H), 4.28ppm (2H), 3.75ppm (2H), 3.63ppm (2H), the results show that the ether segment content of the copolymer is 20wt%.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com