Preparation method of double-enzyme glucose sensor based on graphene

A glucose sensor and graphene technology, which can be used in instruments, scientific instruments, measuring devices, etc., can solve problems such as interference signals, and achieve the effects of good biocompatibility, simple and easy preparation method, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

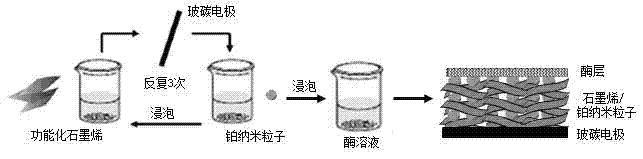

[0023] (1) Preparation of functionalized graphene: 10 mg of ionic liquid [BMIM]PF 6 Add to 0.5 mg / mL graphite oxide aqueous solution and sonicate for one hour to obtain a uniformly dispersed mixture. Then KOH (10 mg) was added and ultrasonicated for 30 minutes to obtain a transparent and uniform solution. At 60°C, reflux for 24 hours to obtain functionalized graphene. The obtained product was centrifuged, washed with ethanol and water until neutral, and dried in vacuum at 60°C.

[0024] (2) Preparation of Pt nanoparticles: 1wt% H 2 PtCl 6 Aqueous solution (1ml) was added to 100ml of water and heated to boiling point. Add 3ml of 1wt% sodium citrate aqueous solution quickly again, and keep the boiling point temperature for 1 hour.

[0025] (3) Preparation of dual-enzyme glucose sensor:

[0026] a. Pretreatment of glassy carbon electrodes: firstly polish the glassy carbon electrodes (φ=3mm) with metallographic sandpaper, and then use 1.0μm, 0.3μm and 0.05μm Al 2 o 3 The s...

Embodiment 2

[0030] (1) Preparation of functionalized graphene: 10 mg of ionic liquid [BMIM]BF 4 Add to 0.5 mg / mL graphite oxide aqueous solution and sonicate for one hour to obtain a uniformly dispersed mixture. Then KOH (10 mg) was added and ultrasonicated for 30 minutes to obtain a transparent and uniform solution. At 80°C, reflux reaction for 48 hours to obtain functionalized graphene, the obtained product was centrifuged, washed with ethanol and water until neutral, and dried in vacuum at 60°C.

[0031] (2) Preparation of Pt nanoparticles: 1wt% H 2 PtCl 6 Aqueous solution (1ml) was added to 100ml water and heated to boiling point. Add 3ml of 1wt% sodium citrate aqueous solution quickly again, and keep the boiling point temperature for 1 hour.

[0032] (3) Preparation of dual-enzyme glucose sensor:

[0033]a. Pretreatment of the glassy carbon electrode: First, the glassy carbon electrode (φ=3mm) is polished with metallographic sandpaper, and then polished to a mirror surface with...

Embodiment 3

[0036] (1) Preparation of functionalized graphene: 10 mg of ionic liquid 1-octyl-3-methylimidazolium bromide was added to 0.5 mg / mL graphite oxide aqueous solution and sonicated for one hour to obtain a uniformly dispersed mixture. Then KOH (10 mg) was added and ultrasonicated for 30 minutes to obtain a transparent and uniform solution. At 70°C, reflux reaction for 48 hours to obtain functionalized graphene, the obtained product was centrifuged, washed with ethanol and water until neutral, and dried in vacuum at 60°C.

[0037] (2) Preparation of Pt nanoparticles: 1 wt % H 2 PtCl 6 Aqueous solution (1ml) was added to 100ml of water and heated to boiling point. Add 3 ml of 1 wt % sodium citrate aqueous solution quickly and keep the boiling point temperature for 3 hours.

[0038] (3) Preparation of dual-enzyme glucose sensor:

[0039] a. Pretreatment of glassy carbon electrodes: firstly polish the glassy carbon electrodes (φ=3mm) with metallographic sandpaper, and then use 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com