Method for preparing flexible display module based on PDLC

A flexible display and flexible substrate technology, applied in nonlinear optics, optics, instruments, etc., can solve the problems of restricting the development and lack of printed flexible displays, reduce production costs, improve qualification rates, and achieve mass production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, and the following embodiments are not intended to limit the present invention.

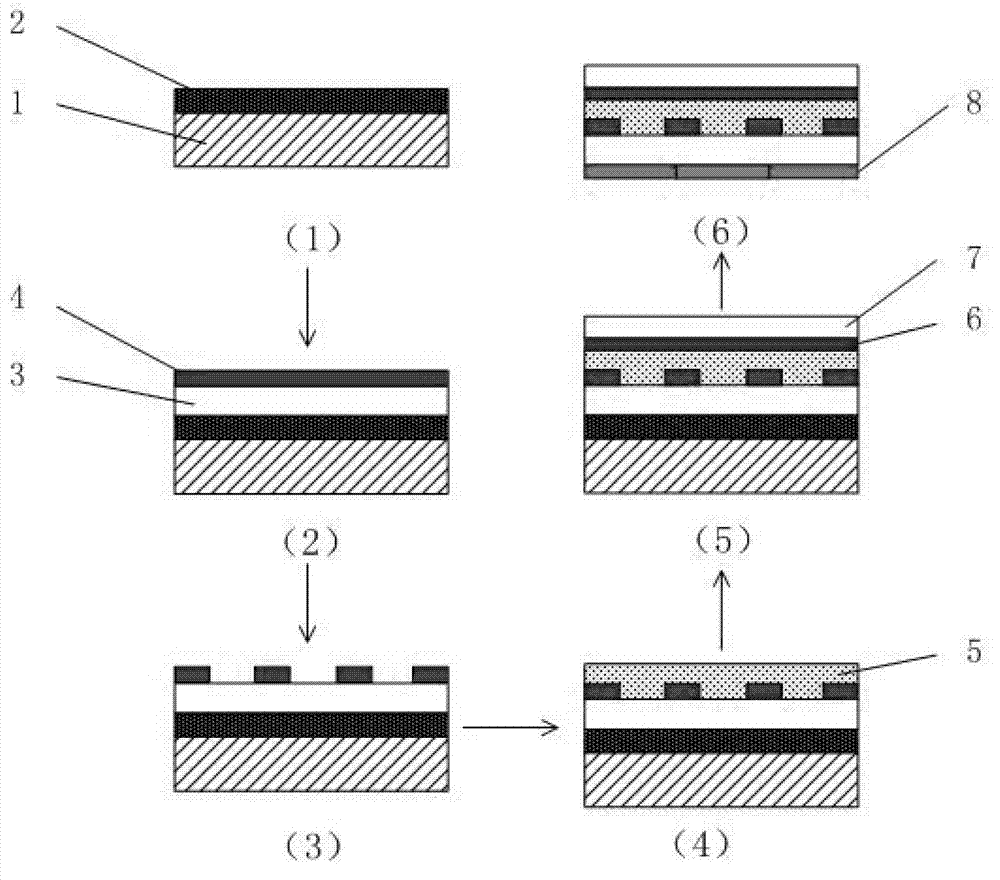

[0022] In this example, refer to figure 1 , a method for preparing a flexible display module based on PDLC, comprising the following steps:

[0023] (1) Select silicon or glass wafers with high flatness and single-sided polishing as the hard substrate 1. The surface roughness of the hard substrate 1 is less than 5 μm, and the hard substrate is cleaned with deionized water, and then baked After drying, coat an adhesive layer 2 on the surface of the hard substrate 1 . First, prepare the hard substrate 1 and the adhesive layer 2. The hard substrate 1 is a single-polished silicon wafer. The hard substrate is ultrasonically cleaned with acetone, ethanol and deionized water, and baked in a vacuum furnace at 180°C. Dry for 3 hours, and then coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com