Device and method for processing waste water with high COD concentration through catalytic wet oxidation

A catalytic wet oxidation, high-concentration technology, applied in the direction of oxidized water/sewage treatment, etc., can solve the problem of harsh catalytic wet oxidation reaction conditions, and achieve good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Catalytic wet oxidation technology is used to treat high-concentration COD wastewater. The COD value of wastewater is 17000mg / L, the reaction temperature is 150°C, the oxygen partial pressure is 1Mpa, and the volume ratio of gas-liquid raw materials is 15:1 in the standard state. Ferric sulfate is used as the condition. Catalyst, with Fe 3+ Calculate its catalyst dosage to be 0.006mol / L.

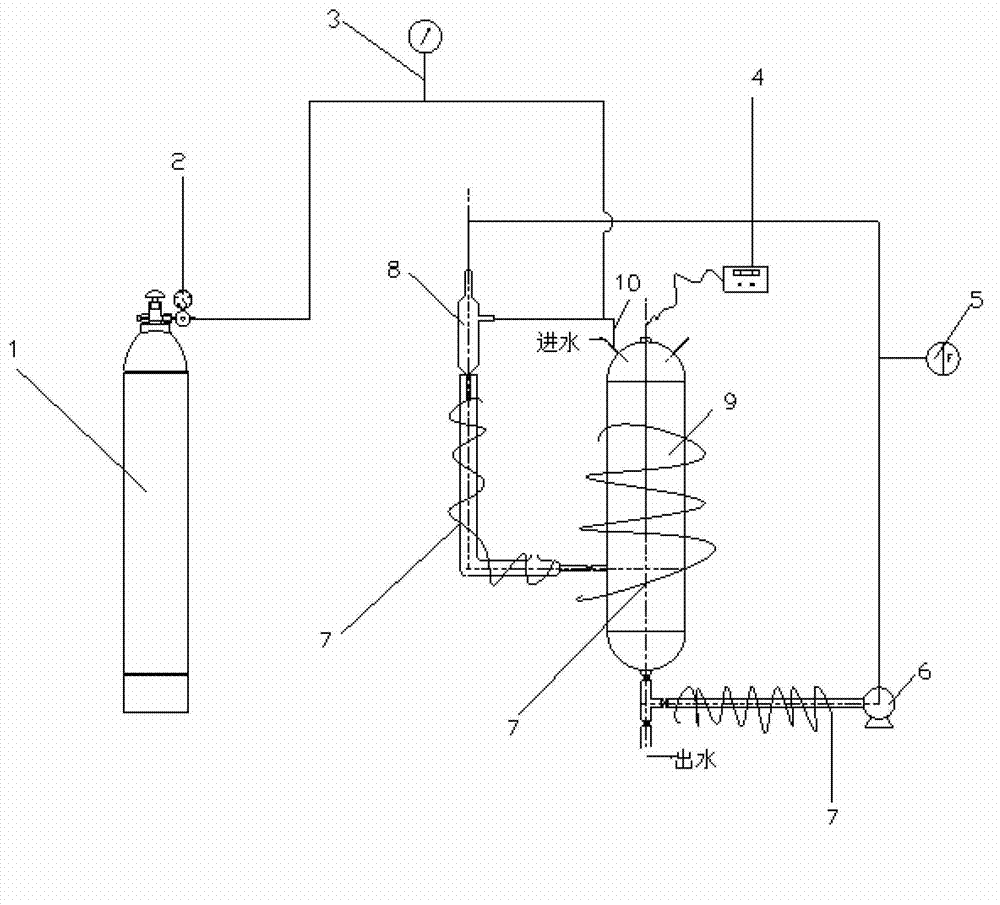

[0020] The specific operation steps are: 1) After the catalyst is completely dissolved in the wastewater, add it from the top of the reactor, start the magnetic pump to make the wastewater circulate in the reaction device, and then pass the oxygen into the reaction system through the control of the deceleration valve, when the whole system When the internal oxygen partial pressure is 1Mpa, stop the oxygen supply, start the heating device and the temperature controller to ensure that the temperature in the system reaches 150°C, stop the temperature rise and maintain the reaction temper...

Embodiment 2

[0023] In the test of using catalytic wet oxidation technology to treat high-concentration COD wastewater, the COD value of wastewater is 17,000mg / L, the reaction temperature is 130°C, the partial pressure of oxygen is 0.5Mpa, and the volume ratio of gas-liquid raw materials is 10:1 in the standard state. Copper as a catalyst, by Cu 2+ The catalyst dosage is calculated to be 0.06 mol / L. The treatment method was the same as in Example 1, and the results showed that after 1.5h, the COD of the effluent was 870 mg / L, and the removal rate reached 94.88%, and its BOD 5 / COD cr Improved from 0.19 to 0.8.

Embodiment 3

[0025] In the test of using catalytic wet oxidation technology to treat high-concentration COD wastewater, the COD value of wastewater is 17,000mg / L, the reaction temperature is 110°C, the partial pressure of oxygen is 0.25Mpa, and the volume ratio of gas-liquid raw materials is 12:1 in the standard state. Manganese as a catalyst, with Mn 2+ The catalyst dosage is calculated to be 0.05 mol / L. The treatment method was the same as in Example 1, and the results showed that after 2.5 hours, the COD of the effluent was 978 mg / L, and the removal rate reached 93.57%, and its BOD 5 / COD cr From 0.19 to 0.74.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com