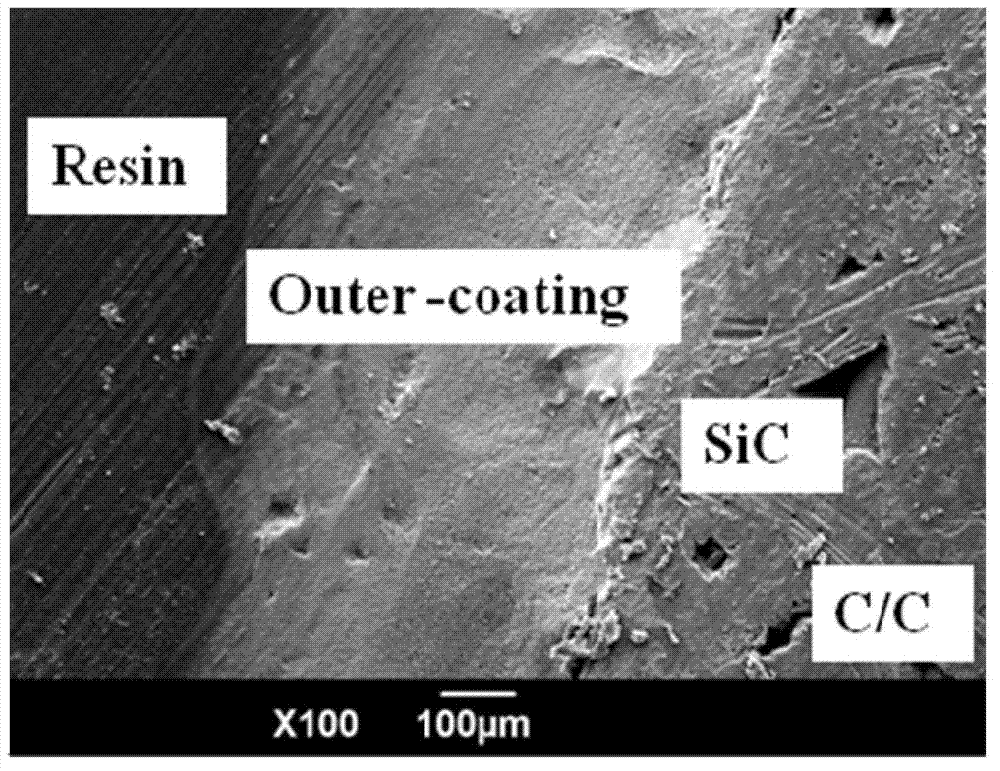

Method for preparing carbon/carbon composite MoSi2-ZrSiO4-SiC gradient complex outer coating

A carbon composite material and outer coating technology, which is applied in the field of preparing carbon/carbon composite material composite outer coating, can solve the problems of easy cracking on the surface of the outer coating, cannot be completed in one preparation, and insufficient coating thickness, and achieves excellent resistance to The effect of high temperature oxidation performance, easy control of deposition process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Take commercially available molybdenum disilicide powder with a particle size of 3-6 μm and micron-scale analytically pure ZrSiO through dry ball milling 4 Powder and nano-silicon carbide powder with a particle size of 40nm, according to ZrSiO 4 :SiC:MoSi 2 = 1:10:1 mass ratio mixed and dispersed in ethanol with a purity ≥ 99.8% to prepare suspension A with a concentration of 40g / L;

[0031] By ZrSiO 4 :SiC:MoSi 2 = 5:5:5 mass ratio mixed and dispersed in ethanol with a purity ≥ 99.8% to prepare a suspension B with a concentration of 50g / L;

[0032] By ZrSiO 4 :SiC:MoSi 2 = 12:5:10 mass ratio mixed and dispersed in ethanol with a purity ≥ 99.8% to prepare a suspension C with a concentration of 60g / L;

[0033] 2) Put the suspensions A, B, and C into a 500W ultrasonic generator and vibrate for 100 minutes, take them out, and place them on a magnetic stirrer for 12 hours;

[0034] 3) Add elemental tellurium with a purity of ≥99.7% to the suspensions A, B, and C r...

Embodiment 2

[0039] 1) Take commercially available molybdenum disilicide powder with a particle size of 3-6 μm and micron-scale analytically pure ZrSiO through dry ball milling 4 Powder and nano-silicon carbide powder with a particle size of 40nm, according to ZrSiO 4 :SiC:MoSi 2 =5:13:8 mass ratio mixed and dispersed in ethanol with a purity ≥99.8% to prepare a suspension A with a concentration of 40g / L;

[0040] By ZrSiO 4 :SiC:MoSi 2 = 10:10:12 mass ratio mixed and dispersed in ethanol with a purity ≥ 99.8% to prepare a suspension B with a concentration of 50g / L;

[0041] By ZrSiO 4 :SiC:MoSi 2 = 15:10:12 mass ratio mixed and then dispersed in ethanol with a purity ≥ 99.8% to prepare a suspension C with a concentration of 60g / L;

[0042] 2) Put the suspensions A, B, and C into an 800W ultrasonic generator to vibrate for 80 minutes, take them out, and place them on a magnetic stirrer for 18 hours;

[0043] 3) Add elemental tellurium with a purity of ≥99.7% to the suspensions A, B,...

Embodiment 3

[0048] 1) Take commercially available molybdenum disilicide powder with a particle size of 3-6 μm and micron-scale analytically pure ZrSiO through dry ball milling 4 Powder and nano-silicon carbide powder with a particle size of 40nm, according to ZrSiO 4 :SiC:MoSi 2 = 10:20:10 mass ratio mixed and then dispersed in ethanol with a purity ≥ 99.8% to prepare suspension A with a concentration of 40g / L;

[0049] By ZrSiO 4 :SiC:MoSi 2 =8:12:10 mass ratio mixed and dispersed in ethanol with a purity ≥ 99.8% to prepare a suspension B with a concentration of 50g / L;

[0050] By ZrSiO 4 :SiC:MoSi 2 = 10:1:15 mass ratio mixed and then dispersed in ethanol with a purity ≥ 99.8% to prepare a suspension C with a concentration of 60g / L;

[0051] 2) Put the suspensions A, B, and C into a 1000W ultrasonic generator to vibrate for 60 minutes, take them out, and place them on a magnetic stirrer for 24 hours;

[0052] 3) Add elemental tellurium with a purity of ≥99.7% to the suspensions A, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com