Fluorescence sensing material for Cu2+ and Fe3+ detection and preparation method and application thereof

A fluorescent sensing and base material technology, applied in the field of fluorescent chemical sensing materials, can solve the problems of not being widely used, low detection efficiency, inconvenient to carry, etc., and achieve the effect of simple mechanism of action, fast response, and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

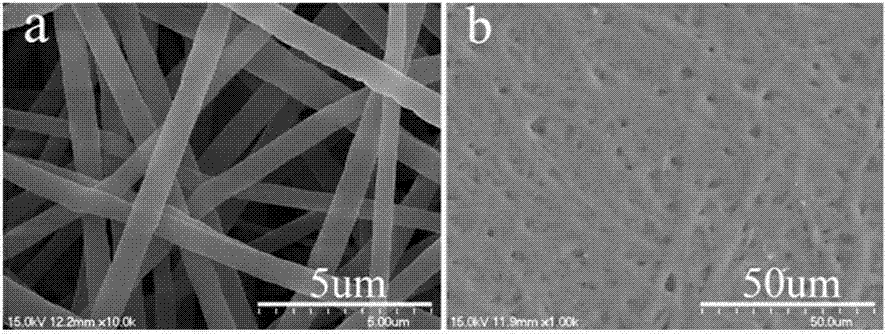

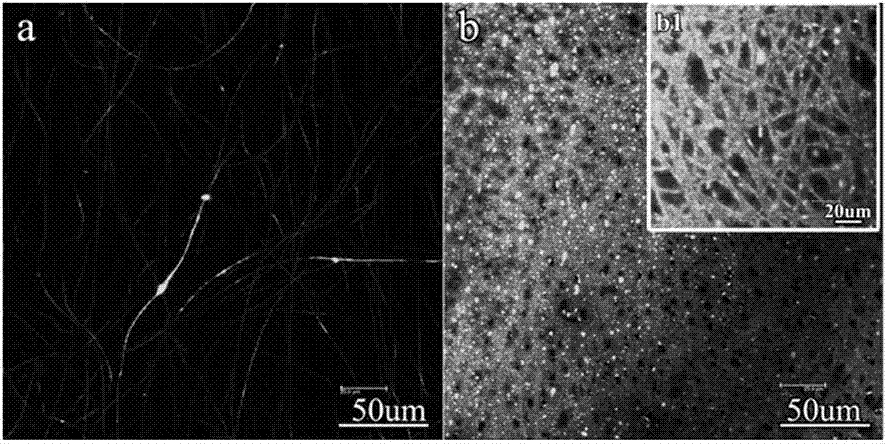

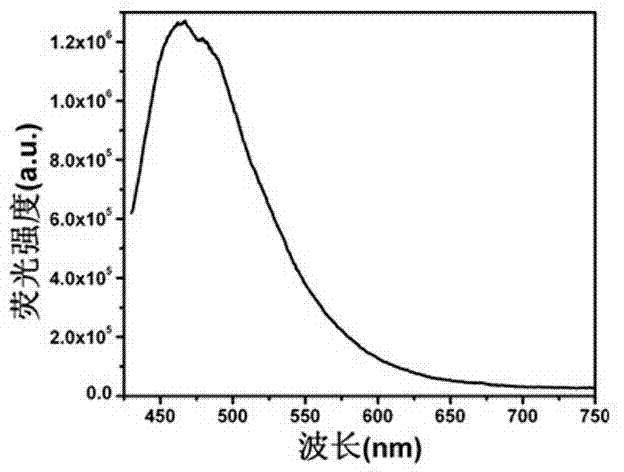

[0026] The method for preparing polyparaphenylene vinylene / polymethyl methacrylate (PPV / PMMA) nanofiber membrane material comprises following two major steps:

[0027] 0.25g polyparaphenylene vinylene precursor (pre-PPV) and 1.25g polymethylmethacrylate (PMMA) were dissolved in 3.50g of N, N-dimethylformamide (DMF) solvent, in Under the condition of temperature of 50-60°C, stir until poly-p-phenylene vinylene precursor (pre-PPV) and polymethyl methacrylate (PMMA) are completely dissolved in N, N-dimethylformamide (DMF ); after the solution was lowered to room temperature, the solution was injected into the spinning solution container of the electrospinning machine, the spinning temperature was room temperature, the output voltage of the high-voltage power supply was 10kV, and the distance between the receiving screen and the spinneret was 12cm. The solution hangs in the shape of droplets at the tip of the gun and forms a Taylor cone, and there is a light yellow fiber film on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com