Colored curable resin composition

A technology of curable resin and composition, applied in nonlinear optics, optics, instruments, etc., which can solve the problem that the brightness of color filters may not be fully satisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0320] Next, the present invention will be described more concretely with reference to examples. Unless otherwise specified, "%" and "part" in an example are mass % and a mass part.

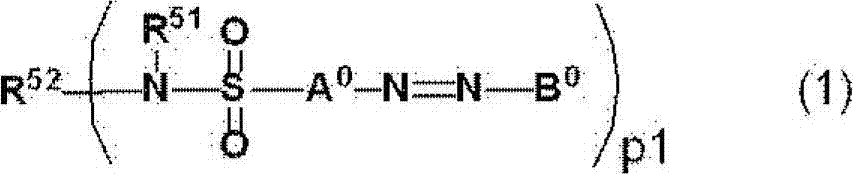

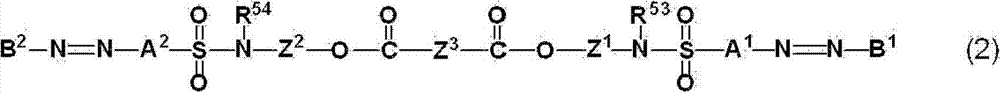

[0321] After adding 200 parts of water to 10 parts of m-toluidine-4-sulfonic acid (the compound represented by the formula (a-2)), it adjusted to pH 7-8 with 30% sodium hydroxide aqueous solution under ice-cooling. The following operations were performed under ice cooling. Add 11.1 parts of sodium nitrite and stir for 30 minutes. After gradually adding 39 parts of 35% hydrochloric acid to prepare a brown solution, the mixture was stirred for 2 hours. An aqueous solution obtained by dissolving 10.1 parts of amide sulfuric acid in 101 parts of water was added to the reaction solution and stirred to obtain a suspension containing a diazonium salt.

[0322]

[0323] Add 125 parts of water and N - After 25 parts of methylpyrrolidone, adjust the pH to 8-9 with 30% aqueous sodium hydroxide soluti...

Synthetic example 2

[0364] Nitrogen gas was flowed in at 0.02 L / min into a flask equipped with a reflux condenser, a dropping funnel, and a stirrer to make a nitrogen atmosphere, 305 parts by mass of ethyl lactate was added, and it was heated to 70° C. while stirring.

[0365] Next, dissolve in 60 mass parts of acrylic acid, acrylic acid 3,4-epoxytricyclic [5.2.1.0 2.6 ] decyl ester (the compound represented by the formula (I-1) and the compound represented by the formula (II-1) are mixed in a molar ratio of 50:50.) Prepare a solution in 240 parts by mass and 140 parts by mass of ethyl lactate, This solution was dropped into a flask kept at 70° C. using a dropping funnel over 4 hours.

[0366]

[0367] On the other hand, 30 parts by mass of the polymerization initiator 2,2'-azobis(2,4-dimethylvaleronitrile) was dissolved in 225 parts by mass of ethyl lactate over 4 hours using another dropping funnel. The solution was added dropwise to the flask. After the titration of the solution of the po...

Embodiment 1

[0379] [Preparation of colored curable resin composition]

[0380] Mix the following components to obtain a colored curable resin composition:

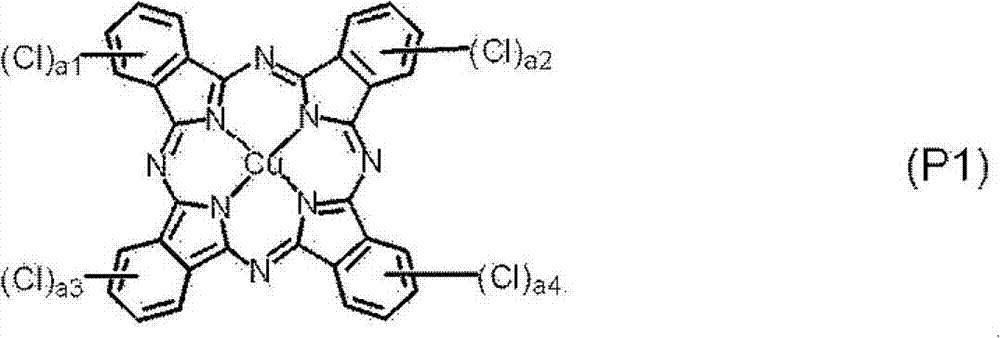

[0381] (A) coloring agent: C.I. Pigment Green 7 (pigment) 38 parts

[0382] Acrylic pigment dispersant 17 parts

[0383] Propylene glycol monomethyl ether acetate 245 parts

[0384] Mix and use a bead mill to fully disperse the pigments to form a pigment dispersion,

[0385] (A) Colorant: 38 parts of dyestuff (b) (yellow dyestuff)

[0386] (B) Resin: Resin B1 (solid content conversion) 40 parts

[0387] (C) Polymerizable compound: 60 parts of dipentaerythritol hexaacrylate (Kayarad DPHA; manufactured by Nippon Kayaku Co., Ltd.)

[0388] (D) Polymerization initiator: 10 parts of N-benzoyloxy-1-(4-phenylsulfonylphenyl)octan-1-one-2-imine (Irgacure OXE 01; manufactured by BASF Corporation)

[0389] (F) Leveling agent: polyether modified silicone oil (Toray Silicone SH8400: manufactured by Toray Dow Corning Co., Ltd.) 0.12 parts

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com