Aluminum-coated nickel cobalt magnesium lithium cathode material and preparation method thereof

A technology of lithium cobalt magnesium oxide and cathode material, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of large irreversible capacity at the first discharge, incomplete reaction of lithium carbonate, deterioration of cycle performance, etc., and achieve high first charge and discharge efficiency. , the effect of reducing cation mixing, improving high temperature performance and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

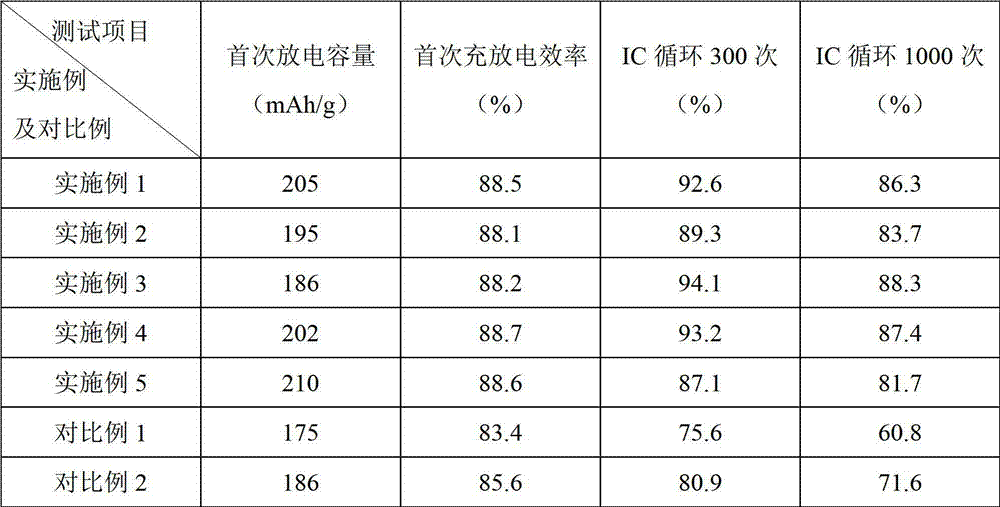

Examples

Embodiment 1

[0029] An aluminum-coated nickel-cobalt lithium magnesium oxide positive electrode material, its chemical formula is: Al 2 o 3 [Li 1.05 Ni 0.8 co 0.15 Mg 0.05 o 2 ].

[0030] A method for preparing an aluminum-coated nickel-cobalt lithium magnesium oxide positive electrode material, the specific steps are as follows:

[0031] (1) Mixing: set the particle size D50 to 10μmNi(OH) 2 7415g of CoC with particle size D50 of 3μm 2 o 4 2204g of MgC with particle size D50 of 2μm 2 o 4 2H 2 O742g battery grade Li with a particle size D50 of 3 μm and a content of 99.5% 2 CO 3 Add 3898g into the high-speed mixer together, so that the molar coefficient ratio Ni:Co:Mg=0.8:0.15:0.05, (Ni+Co+Mg):Li=1:1.05, mix at a speed of 1300r / min for 1h;

[0032] (2) Sintering: Put the mixture in step (1) into a corundum crucible, place it in an atmosphere box furnace, and raise the temperature to 500°C at a rate of 2°C / min in an oxygen atmosphere, keep it warm for 6 hours, and then heat it a...

Embodiment 2

[0038] An aluminum-coated nickel-cobalt lithium magnesium oxide positive electrode material, its chemical formula is: Al 2 o 3 [Li 1.15 Ni 0.8 co 0.1 Mg 0.1 o 2 ].

[0039] A method for preparing an aluminum-coated nickel-cobalt lithium magnesium oxide positive electrode material, the specific steps are as follows:

[0040] (1) Mixing material: Co 2 o 3 829g MgO403g with particle size D50 of 0.5μm and battery grade LiOH2767g with particle size D50 of 2μm and content of 99.5% were added to the high-speed mixer together, so that the molar coefficient ratio Ni:Co:Mg=0.8:0.1:0.1, (Ni+Co +Mg): Li=1:1.15, mixed at 1500r / min for 0.2h;

[0041] (2) Sintering: Put the mixture in step (1) into a corundum crucible, place it in a pusher tunnel kiln, and raise the temperature to 400°C at a rate of 1°C / min in an oxygen atmosphere, keep it warm for 3 hours, and then heat it for 2 Raise the temperature to 700°C at a speed of ℃ / min, keep it warm for 24 hours, then cool down to room t...

Embodiment 3

[0046] An aluminum-coated nickel-cobalt lithium magnesium oxide positive electrode material, its chemical formula is: Al 2 o 3 [LiNi 0.7 co 0.2 Mg 0.1 o 2 ].

[0047] A method for preparing an aluminum-coated nickel-cobalt lithium magnesium oxide positive electrode material, the specific steps are as follows:

[0048] (1) Mixing: set the particle size D50 to 15 μm Ni 2 o 3 5788g of Co with particle size D50 of 0.5μm 3 o 4 1605g of Mg(OH) with particle size D50 of 1μm 2 583g of battery-grade Li with a particle size D50 of 3μm and a content of 99.5% 2 CO 3 Add 3712g into the high-speed mixer together, so that the molar coefficient ratio Ni:Co:Mg=0.7:0.2:0.1, (Ni+Co+Mg):Li=1:1, mix at 800r / min for 2h;

[0049] (2) Sintering: Put the mixture in step (1) into a corundum crucible, place it in a rotary kiln, and raise the temperature to 600°C at a rate of 5°C / min in an oxygen atmosphere, keep it warm for 10 hours, and then heat it up at a rate of 2°C / min. Raise the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com