Heat-accumulation dividing-wall heating rotary kiln device

A rotary kiln and regenerative technology, which is applied in the field of rotary kiln and regenerative partition heating rotary kiln device, can solve the problem that the rotary kiln cannot adapt to multiple purposes, achieve significant economic and social benefits, reduce pollution, improve The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

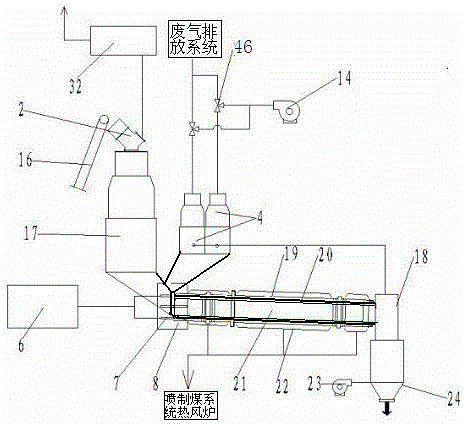

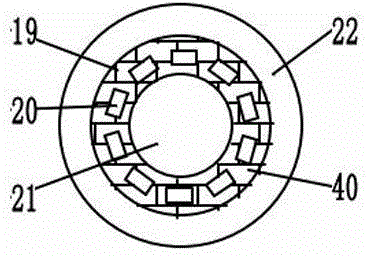

[0030] The regenerative partition heating rotary kiln device of the present invention is as figure 1 As shown, it includes two rotary kiln bodies 19, two heat storage decomposers 4, two silos 17, feeding equipment 16, lime raw material feeding system 3, blower 14, gas turbine 9, steam turbine 13, gas product processing Equipment, discharge equipment and exhaust gas emission system. The steam and gas turbines are coaxially connected to the generator. The gas product processing equipment includes coking gas purification equipment, liquid extraction equipment and chemical unit, and the discharge equipment includes No. 1 cooling fan 23, cooler 24 and coking product sorting equipment 26. No. 1 cooling fan is connected with the cooler, heat storage and decomposition The feed port 2 of the device is connected with the lime raw material feeding system. A heat storage body is installed in the heat storage decomposer, and the heat storage body is a small ceramic ball. The silo is con...

Embodiment 2

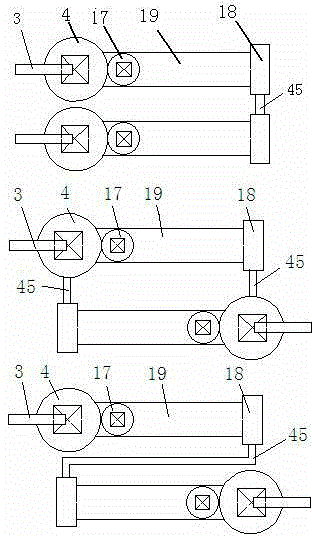

[0033] The second embodiment of the present invention is as figure 2 As shown, the regenerative decomposer is provided with a cooling belt 43, No. 2 cooling fan 29 and an ordinary lime outlet 41. The regenerator in the regenerative decomposer is limestone material, and the No. 2 cooling fan is connected with the cooling belt. No. 1 cooler 23 is provided with steam generators 5 respectively, and the steam generators are respectively connected with steam turbines. No. 1 cooler 23 is provided with steam generators 5, and the steam generators are respectively connected with steam turbines. The limestone enters the thermal storage decomposer 4 through the lime raw material feeding system 3 and the feed port 2, and the flue gas generated by combustion in the combustion chamber passes through the flue gas channels 20 on both sides, is heated in the kiln chamber 21, and then goes to the other side for thermal storage and decomposition Device 4 calcines the limestone material in the ...

Embodiment 3

[0035] The third embodiment of the present invention is used to produce low-sulfur lime and ordinary lime, such as Figure 4 As shown, the device is provided with a carbon dioxide collector 32, and the kiln head 8 is provided with a lime powder injection inlet 33. The heat storage decomposer is provided with a cooling belt 43, No. 2 cooling fan 29 and an ordinary lime outlet 41, and the No. 2 cooling fan 29 is connected with the cooling belt 43. The heat storage body in the heat storage decomposer is calcareous material, checker brick or ceramic ball. The discharge equipment includes a cooler 24 and a No. 1 cooling fan 23 . The No. 1 cooling fan is connected to the cooler, and the cooler is provided with a low-sulfur lime outlet 42 . The upper outlet of the feed bin is connected with the carbon dioxide collector 32 through a pipeline. The thermal storage decomposer is used to produce ordinary lime, the rotary kiln body 19 is used to produce low-sulfur lime, and the silo 17 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com