Method for producing alkaline fertilizer by phosphate rock tailings or low-grade phosphate rock kiln method

A technology for phosphate rock tailings and alkaline fertilizers, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of many raw materials required, high roasting temperature, complex processes, etc., and achieve stable product quality, low energy consumption, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Raw material 1: Phosphate ore tailings, collection location: Guizhou Jinde Mining

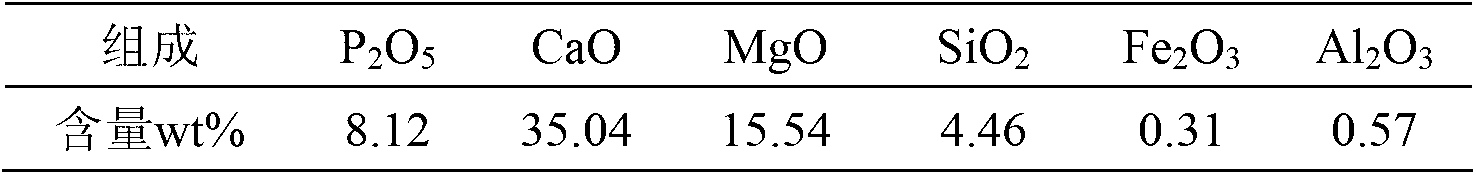

[0037] The main chemical composition of phosphorite tailings in the present embodiment is shown in Table 1:

[0038] Table 1

[0039]

[0040] Raw material 2: Potassium feldspar, collection location: Feicheng, Shandong

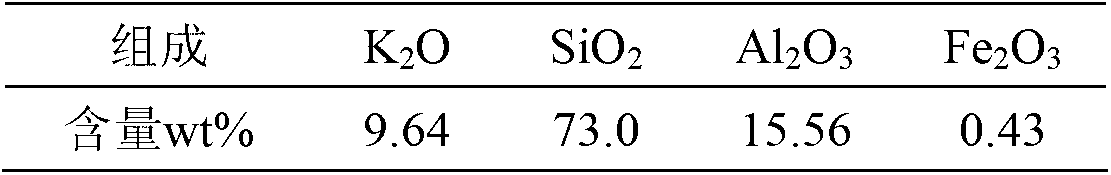

[0041] The main chemical composition of potassium feldspar in the present embodiment is shown in Table 2:

[0042] Table 2

[0043]

Embodiment approach

[0045]The phosphate rock tailings and potassium feldspar are batched with an electronic scale at a mass ratio of 1:0.55, and then anthracite accounting for 4.5% of the total mass of the phosphate rock tailings and potassium feldspar is added, and the mixture is dried by a dryer before use The ball mill is ground to 100 mesh (residual sieve ≤ 5%), the powder is sent to the rotary kiln for roasting, and the high temperature is controlled at 1100°C for 50 minutes. The sintered clinker is quenched in water and cooled to 600°C within 5 minutes. The solid is drained and dried. After crushing, use a ball mill to grind to 80 mesh, and the residual sieve ≤ 5%, after packaging, it is the finished alkaline fertilizer.

[0046] Implementation results:

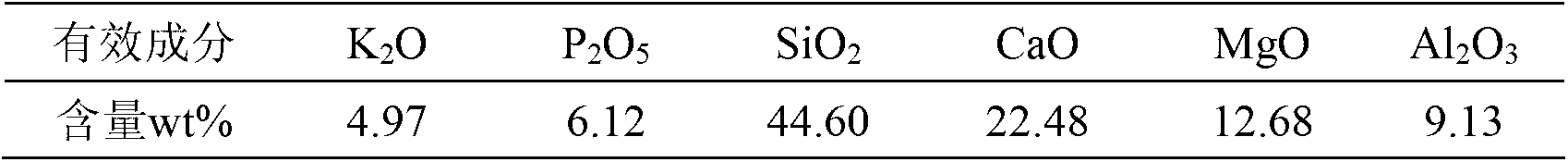

[0047] The active ingredients of the alkaline fertilizer prepared by scanning inductively coupled high-frequency plasma emission spectrometer ICPS-7500 are shown in the following table 3:

[0048] table 3

[0049]

[0050] It can be s...

Embodiment 2

[0052] Raw material 1: Phosphate ore tailings, collection location: Guizhou Jinde Mining

[0053] The main chemical composition of phosphorite tailings in the present embodiment is shown in Table 4:

[0054] Table 4

[0055]

[0056] Raw material 2: Potassium feldspar, collection location: Qiping, Guizhou

[0057] The main chemical composition of potassium feldspar in the present embodiment is shown in Table 5:

[0058] table 5

[0059]

[0060] method of execution:

[0061] The phosphate rock tailings and potassium feldspar are mixed with an electronic scale at a mass ratio of 1:0.6, and then anthracite accounting for 5% of the total mass of the phosphate rock tailings and potassium feldspar is added, and the mixture is dried by a dryer before use The ball mill is ground to 120 mesh (residual sieve ≤ 5%), the powder is sent to the rotary kiln for roasting, the high temperature is controlled at 1150°C for 40 minutes, the sintered clinker is cooled to 500°C within 5 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com