A kind of preparation method and application of acetic acid hydrogenation catalyst

A hydrogenation catalyst and catalyst technology are applied in the preparation of organic compounds, chemical instruments and methods, preparation of hydroxyl compounds, etc., and can solve the problems of increasing the amount of by-product acetone, reducing the yield and purity of ethanol, etc. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

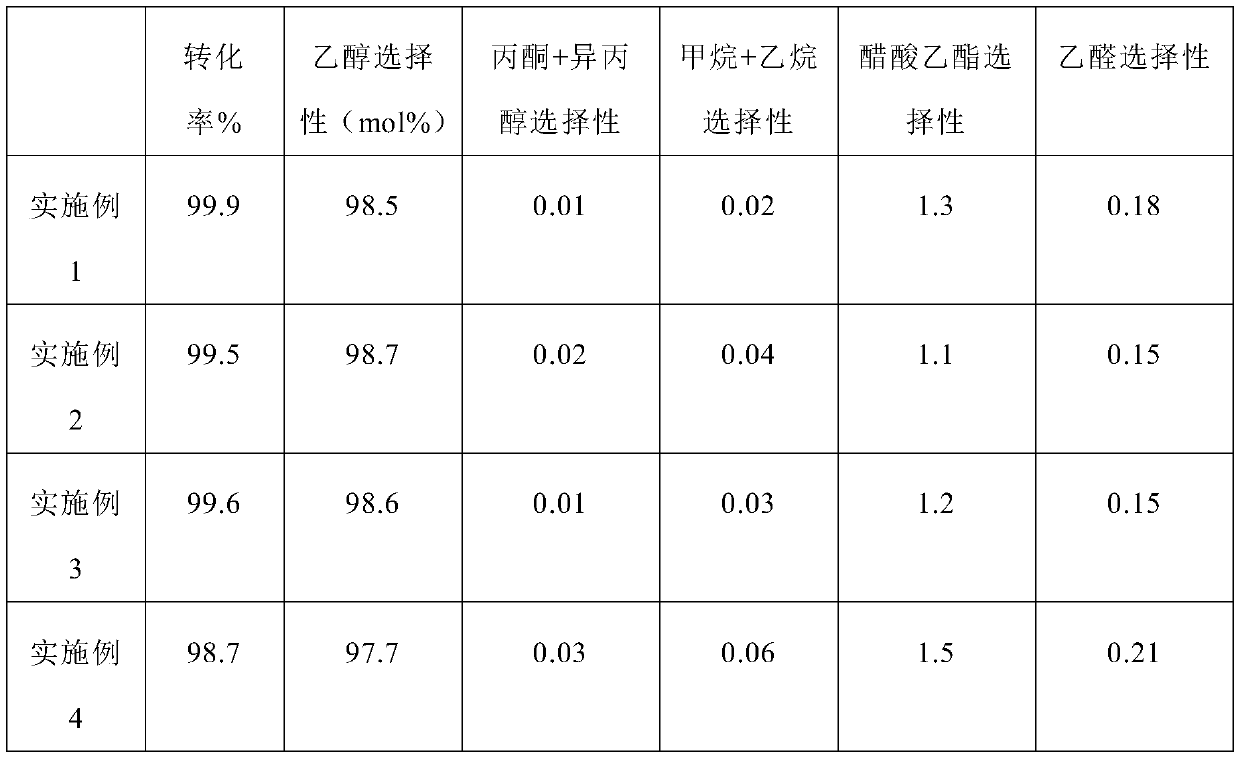

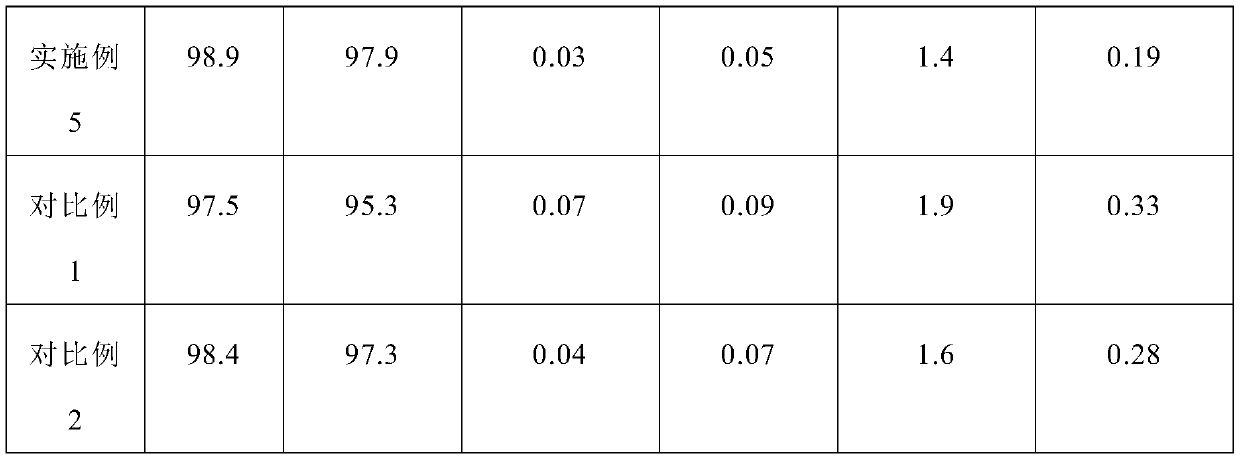

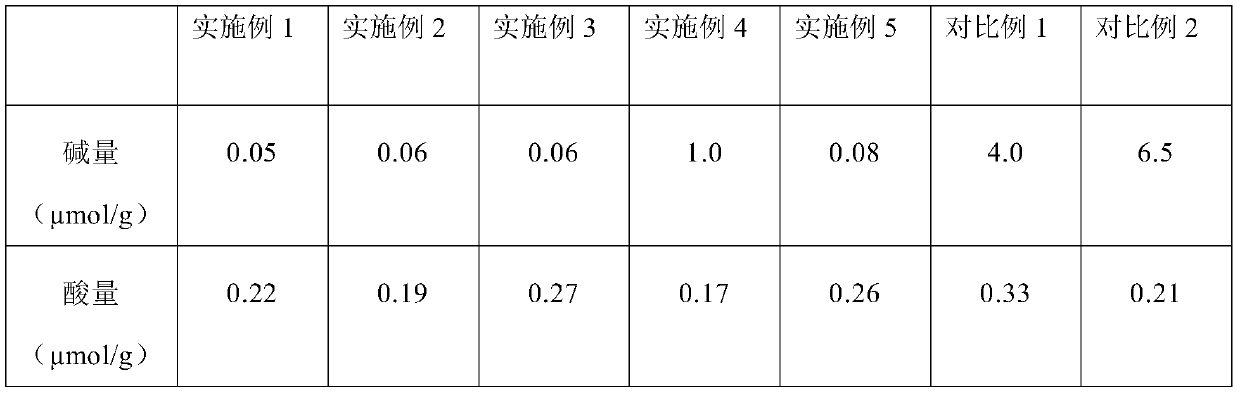

Examples

Embodiment 1

[0025] The present embodiment provides a kind of preparation method of acetic acid hydrogenation catalyst, comprises the steps:

[0026] (1) adding cobalt nitrate and calcium nitrate into water, after stirring uniformly, adding ferric nitrate and tin nitrate, after stirring uniformly, to obtain soaking solution;

[0027] (2) adding sodium carbonate to the soaking solution to form a precipitation solution, adding a silica carrier to the precipitation solution, aging for 3 hours under hydrothermal conditions at a temperature of 80° C., and filtering to obtain a filtered solid;

[0028] (3) The amount of sodium carbonate on which the filtered solid is cleaned is less than 2% of the mass of the filtered solid, dried at a temperature of 100°C, and then roasted at 300°C to obtain the catalyst precursor;

[0029] (4) Place the catalyst precursor in a closed reaction vessel, feed carbon dioxide gas until the partial pressure is 150kpa, control the temperature in the reaction vessel at...

Embodiment 2

[0032] The present embodiment provides a kind of preparation method of acetic acid hydrogenation catalyst, comprises the steps:

[0033] (1) adding copper nitrate and calcium nitrate to water, after stirring evenly, adding ferric nitrate and molybdenum nitrate, after stirring uniformly, to obtain the soaking solution;

[0034] (2) adding sodium carbonate to the soaking solution to form a precipitation solution, adding a silica carrier to the precipitation solution, aging for 5 hours under hydrothermal conditions at a temperature of 70° C., and filtering to obtain a filtered solid;

[0035] (3) cleaning and filtering the solid to the amount of sodium carbonate on it is less than 2% of the mass of the filtered solid, drying at a temperature of 80°C, and roasting at 600°C to obtain the catalyst precursor;

[0036] (4) Place the catalyst precursor in a closed reaction vessel, feed carbon dioxide gas until the partial pressure is 250kpa, control the temperature in the reaction vess...

Embodiment 3

[0039] The present embodiment provides a kind of preparation method of acetic acid hydrogenation catalyst, comprises the steps:

[0040] (1) adding copper nitrate and barium nitrate to water, after stirring evenly, adding tungsten nitrate and molybdenum nitrate, after stirring evenly, to obtain the soaking solution;

[0041] (2) adding sodium carbonate to the soaking solution to form a precipitation solution, adding a zirconia carrier to the precipitation solution, aging for 1 hour under hydrothermal conditions at a temperature of 90° C., and filtering to obtain a filtered solid;

[0042](3) The amount of sodium carbonate on which the filtered solid is cleaned is less than 2% of the mass of the filtered solid, dried at a temperature of 150° C., and then roasted at 450° C. to obtain the catalyst precursor;

[0043] (4) Place the catalyst precursor in a closed reaction vessel, feed carbon dioxide gas until the partial pressure is 200kpa, control the temperature in the reaction v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com