Preparation method of high-viscosity pelletizing sodium carboxymethylcellulose

A high-viscosity technology of sodium carboxymethyl cellulose, which is applied in the field of chemical modification of natural polymer materials, can solve the problems of adverse effects on the health of operators, difficult dispersion of carboxymethyl cellulose, and the need for 16 to 24 hours. Achieve the effects of preventing massive structural damage, good salt-to-stick ratio, and less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

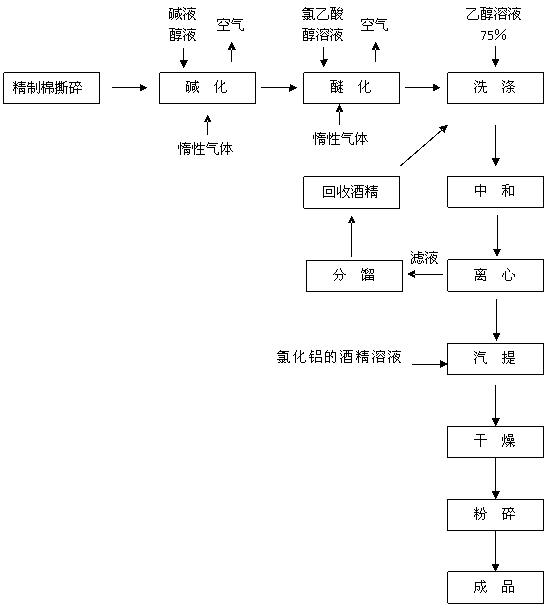

Image

Examples

Embodiment 1

[0022] Put a certain amount of shredded refined cotton, a mixture of 2.00 times the mass (that is, based on the amount of refined cotton, the same below) of ethanol solution and 1.25 times the mass of sodium hydroxide solution into the kneader. , remove the air in the kneader, make the vacuum degree reach at least 0.06MPa, fill the inert gas into the kneader, make the internal pressure of the kneader greater than 0.02MPa, stir and alkalinize for 60 minutes, add 1.23 times the mass of chloroacetic acid in ethanol Spray the solution evenly into the kneader, remove the air in the kneader, make the vacuum degree reach at least 0.06MPa, then fill the inert gas into the kneader, make the internal pressure of the kneader greater than 0.02MPa, and then carry out the etherification reaction, The temperature is raised to 60-90°C, and the reaction is continued for 50 minutes to obtain a crude sodium carboxymethylcellulose product. After washing, neutralization, and centrifugation, the pro...

Embodiment 2

[0024] Put a certain amount of shredded refined cotton into the kneader with a mixture of 1.80 times the mass of ethanol solution and 1.30 times the mass of sodium hydroxide solution. After feeding, remove the air in the kneader to make the vacuum degree reach at least 0.06MPa, fill the inert gas into the kneader, make the internal pressure of the kneader greater than 0.02MPa, stir and alkalinize for 50 minutes, spray 1.30 times the mass of chloroacetic acid ethanol solution evenly into the kneader, and exclude the kneader Air inside, make the vacuum degree reach at least 0.06MPa, then fill the inert gas into the kneader, make the internal pressure of the kneader more than 0.02MPa, then carry out etherification reaction, the temperature rises to 60-90°C, and the reaction lasts for 60 minutes , to obtain the crude sodium carboxymethyl cellulose product, after washing, neutralization and centrifugation, the product enters the stripper while adding 1.5 times the concentration of 1...

Embodiment 3

[0026] Put a certain amount of shredded refined cotton into the kneader with a mixture of 1.50 times the mass of ethanol solution and 1.20 times the mass of sodium hydroxide solution. After feeding, remove the air in the kneader to make the vacuum degree reach at least 0.06MPa, fill the inert gas into the kneader, make the internal pressure of the kneader greater than 0.02MPa, stir and alkalinize for 70 minutes, spray the ethanol solution of 1.20 times the mass of chloroacetic acid evenly into the kneader, and exclude the kneader The air in the kneader makes the vacuum degree reach at least 0.06MPa, and then fills the inert gas into the kneader, so that the internal pressure of the kneader is greater than 0.02MPa, and then carries out the etherification reaction, the temperature rises to 60-90°C, and the reaction lasts for 70 minutes , to obtain the crude sodium carboxymethyl cellulose product, after washing, neutralization, and centrifugation, the product enters the stripper w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com