Method for extracting sialic acid from yolk powder

A technology of egg yolk powder and bird's nest, applied in fermentation and other directions, can solve the problems of difficult degreasing, low product yield, high hydrolysis temperature, etc., and achieve the effect of no environmental pollution, high product content, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0008] Example 1. Take 100kg of egg yolk powder, soak it in 650kg of deionized water, stir for 30min at a temperature of 25°C, add 1kg of bromelain, stir for 10min, control the temperature at 27°C, leave it for 15hr, add sodium alginate with a molecular weight of 100,000 and 15% after stirring 100kg, stir evenly, let it stand for 30min, filter the precipitate with a centrifuge, take the filtrate, add 6% acetic acid to adjust the pH to 4, pass through a macroporous resin column (250kg), collect the eluate, and put it in the perhydrogenated cationic ion exchange Column (100kg), collect the acidic eluate, pass through the ammonium type cation exchange column (200kg), gradient elution, collect the PH3 eluate, adjust the pH7 with 10% sodium carbonate. Centrifuge and filter, place at -5°C for 12 hours, remove the precipitate, concentrate and crystallize, and dry to obtain the bird's nest acid product with a yield of 22.5%. If the product is dark in color, it can be decolorized with ...

example 2

[0009] Example 2. Take 200kg of egg yolk powder, soak it in 1500kg of deionized water, stir for 30min at a temperature of 25°C, add 0.7kg of bromelain, stir for 15min, control the temperature at 25°C, leave it for 18hr, add alginic acid with a molecular weight of 150,000 and 15% after stirring Sodium 200kg, stir evenly, let it stand for 30min, filter the precipitate with a centrifuge, take the filtrate, add 8% acetic acid to adjust the pH to 4, pass through a macroporous resin column (300kg), collect the eluate, and put Exchange column (200kg), collect acidic eluent, ammonium type cation exchange column (300kg), gradient elution, collect PH4 eluate, adjust pH7 with 15% sodium carbonate. Centrifuge and filter, place at -5°C for 15 hours, remove the precipitate, concentrate and crystallize, and dry to obtain the bird's nest acid product. Yield 27%.

example 3

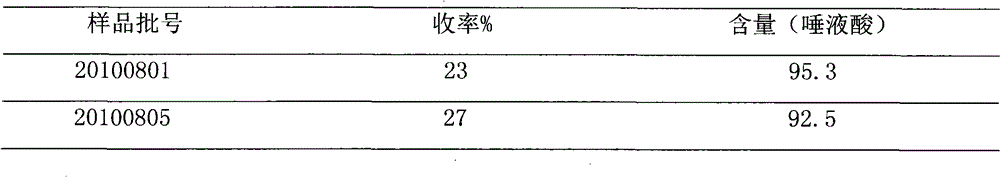

[0010] Example 3. Quality inspection

[0011] 1.2 Method

[0012] 1.2.1 Chromatographic conditions Chromatographic column: Symmetry C18 column (4.6mm×250mm, 5μml); column temperature: 35°C; mobile phase: 1.0% tetrahydrofuran aqueous solution (containing 0.2% phosphoric acid)-acetonitrile (92:8); detection wavelength: 230nm; flow rate: 1.0ml / min; injection volume: 10μl

[0013] 1.2.2 Preparation of sample solution Accurately weigh 1.0mg of bird’s nest acid product, dissolve it in 100ml of water for injection, then add 1ml of 10mg / ml phthalimine hydrochloride solution, heat in 80°C water bath for 40min, and set aside.

[0014] 1.2.3 Preparation of reference substance solution Take 2ml of N-acetylneuraminic acid (sialic acid) reference substance solution, then add 1ml of 10mg / ml o-phenylenediamine hydrochloride solution, heat in 80°C water bath for 40min, take it out After cooling, after filtering through a 0.45 μm membrane, 10 μl each of the above solution and the reference so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com