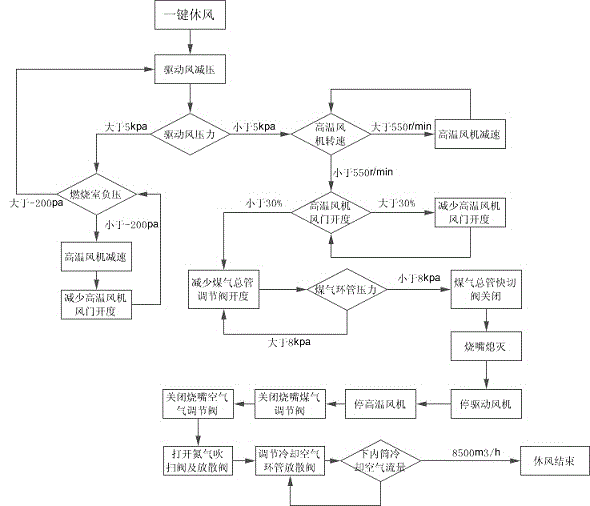

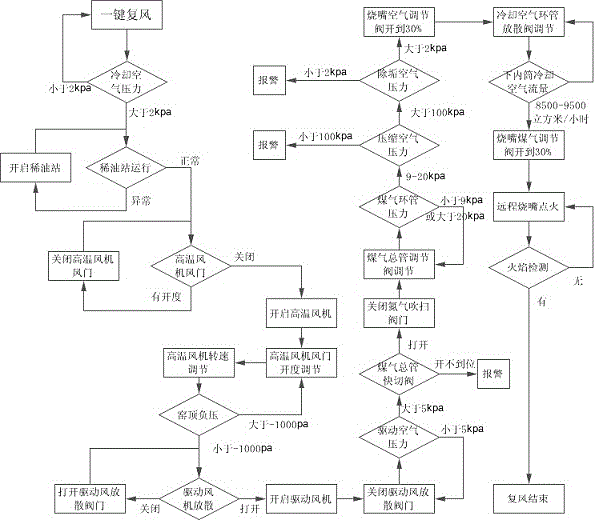

Blowing-down and reblowing control process for annular lime kiln

An annular sleeve, rest and rewind technology, which is applied to furnace control devices, furnaces, lighting and heating equipment, etc., can solve the problems of inconsistent personnel operation levels, difficulty in rest and rewind operations, and high staffing requirements, reducing the need for Cost and labor intensity, the effect of realizing automation and humanization, and improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0015] 1. Equipment requirements:

[0016] (1) High-temperature fan: it can be controlled remotely, and the speed of the high-temperature fan can be adjusted through the opening of the coupler or the frequency conversion parameters; the opening of the damper can be controlled remotely, and there is a feedback signal, and the adjustment step is 1%; the thin oil station can be operated remotely Control, and the running signal and pressure signal have feedback.

[0017] (2) Driving fan: The driving wind pressure can be adjusted by adjusting the frequency of the variable frequency motor; there is a driving wind relief valve, which can remotely control the valve opening; the driving wind pressure has feedback.

[0018] (3) Burner: The burner can be ignited and extinguished remotely; the quick-cut valve of the gas main pipe is interlocked with the pressure of the gas ring pipe; the regulating valve of the gas branch pipe of each burner can be operated remotely; the nitrogen purg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com