Enzyme-linked immunoassay method for aflatoxin in tobacco and tobacco products

A technology for aflatoxin and tobacco products, which is applied in measuring devices, instruments, scientific instruments, etc., to achieve the effects of simple operation steps, accelerated sample detection speed, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

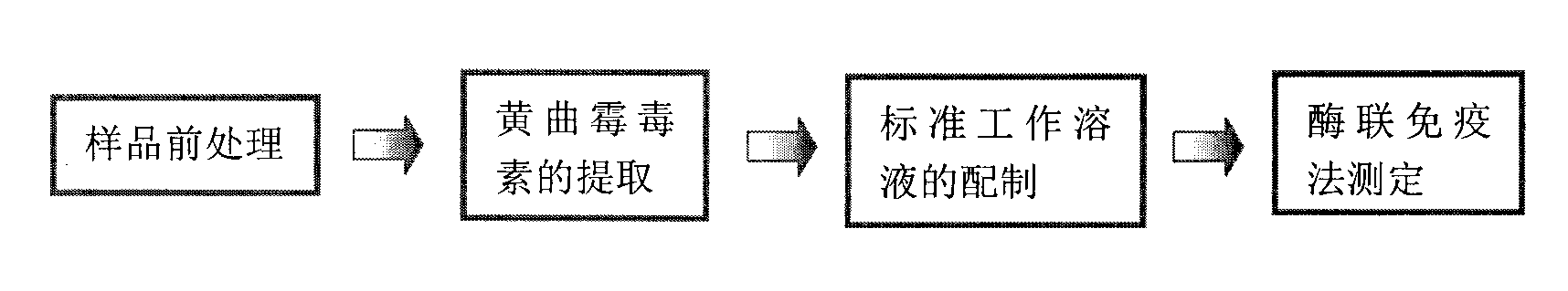

[0036] Below in conjunction with accompanying drawing, the present invention will further detail the specific technological process as follows:

[0037] 1. Sample pretreatment: Weigh about 20 grams of tobacco leaf samples or tobacco products. Samples not to be analyzed immediately should be stored in the refrigerator. The collected tobacco leaf samples or shredded tobacco samples were dried at 40°C, then crushed and passed through a 40-mesh sieve, and mixed thoroughly before sampling.

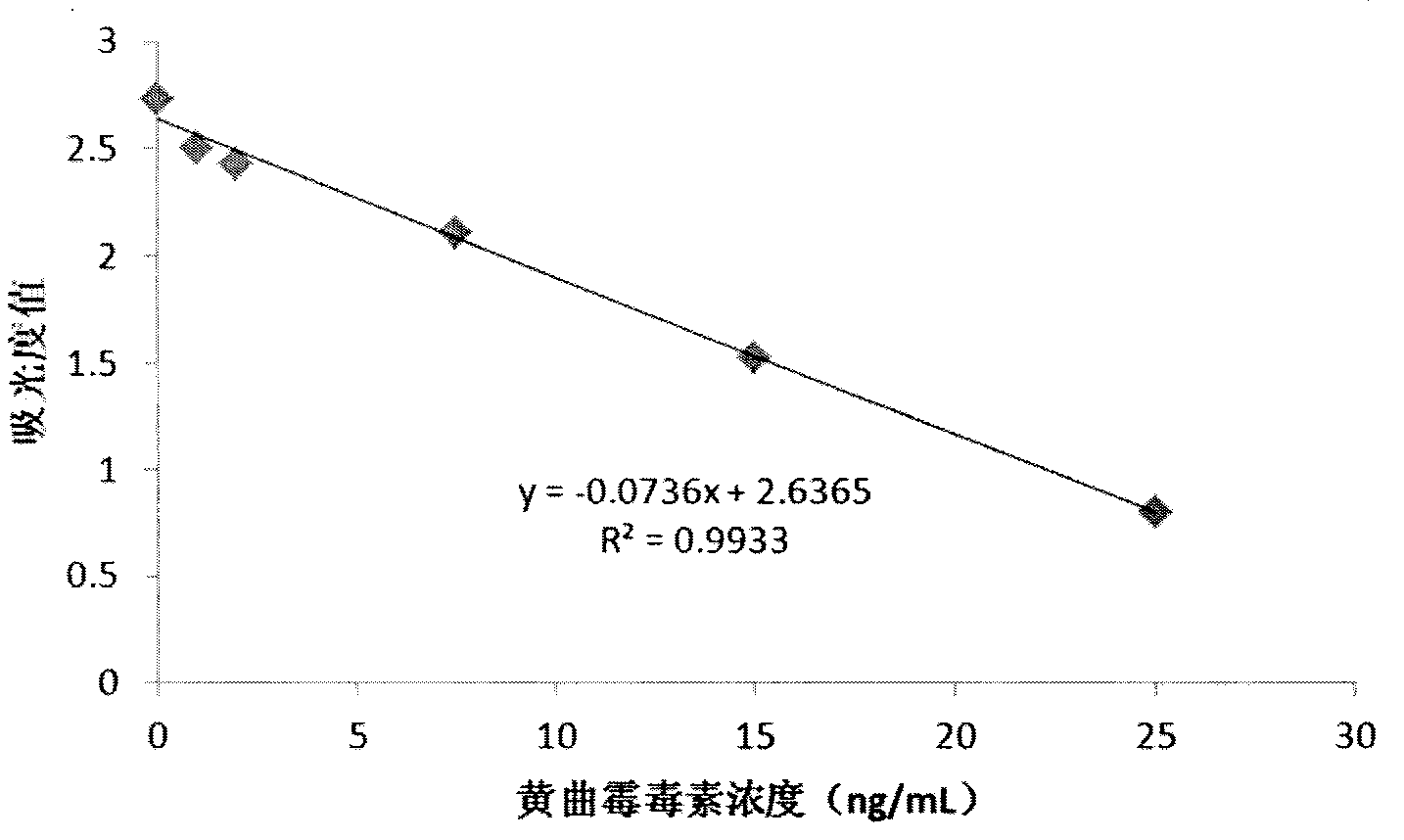

[0038] 2. Extraction of aflatoxin in the sample: Weigh 5g (accurate to 0.1g) of smoke powder sample and 0.5g of sodium chloride into a 100mL conical flask with a stopper. Add 20 mL of 80% methanol in water. Close the lid and vortex on a shaker at high speed for 5 minutes. Allow the sample to settle by standing for 3 minutes. Filter 10 mL of the extract with glass fiber filter paper. Collect the filtrate into a clean container. Take 5mL of extract, add 20mL of water to dilute, mix well and ...

example 1

[0054] 1. Reagents and instruments:

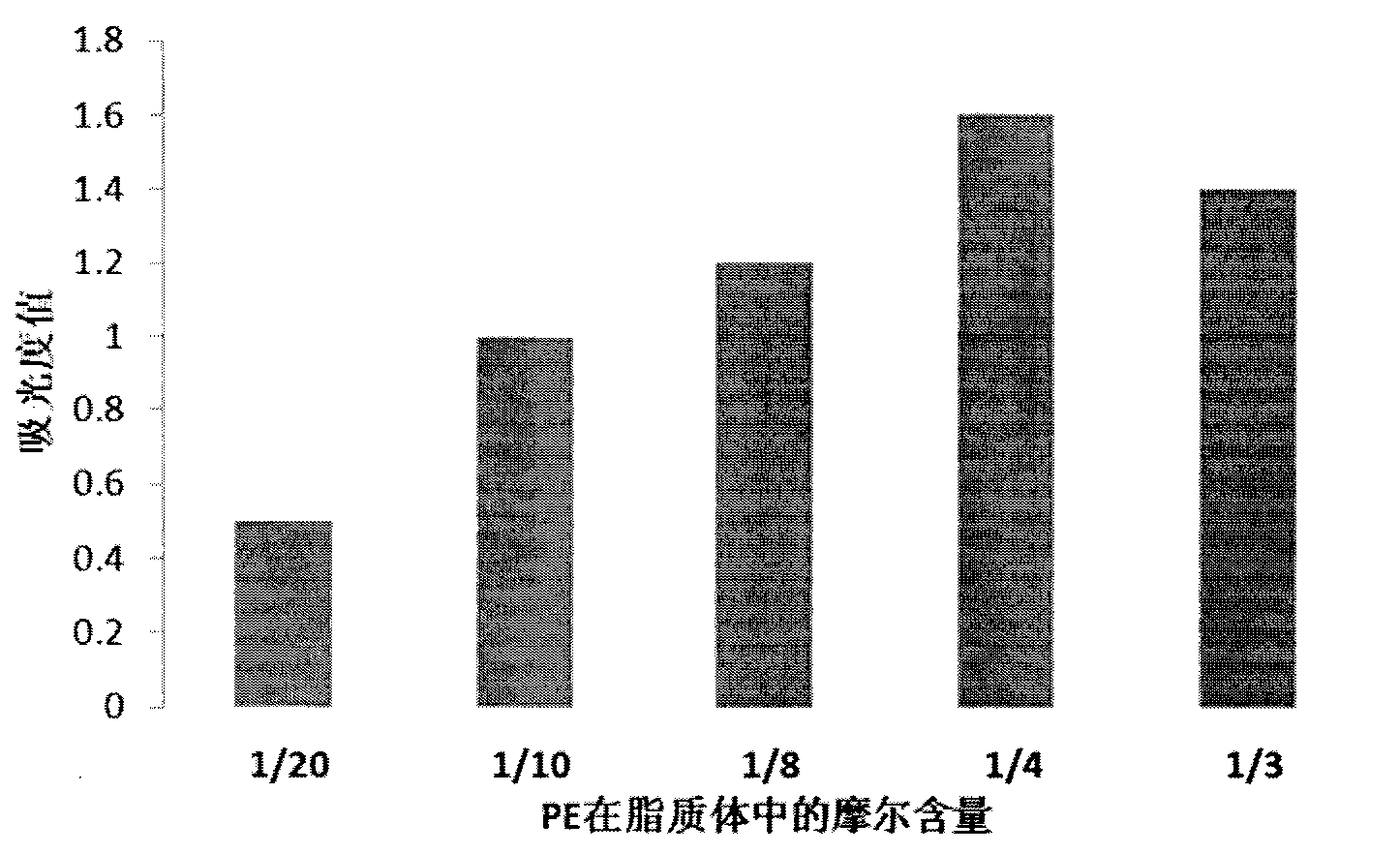

[0055] Microplate reader (MD, USA); 96-well microplate plate (Corning, USA), aflatoxin, lecithin (PC), cephalin (PE), horseradish peroxidase (HRP), bovine serum albumin ( BSA), carbodiimide hydrochloride (EDC), N-hydroxysuccinimide (NHS), and tetramethylbenzidine (TMB) were purchased from SIGMA. Rabbit anti-aflatoxin antibody was purchased from Glory Science (Glory Science, Texas, USA). The rest of the reagents were of analytical grade, and the water used was double distilled water.

[0056] 2. Sample pretreatment and extraction of aflatoxin: Weigh about 5 pieces of tobacco leaf samples, cut the tobacco leaf samples into pieces no larger than 3cm×3cm with scissors, and place the cut samples on a balance to weigh to an accuracy of 0.1g. After recording the weighing value, the tobacco leaf samples were placed in a weighing bottle and dried at 40°C, then crushed and passed through a 40-mesh sieve, and mixed thoroughly before sampling. We...

example 2

[0060] According to the method described in Example 1, the aflatoxin contents of tobacco leaf sample B and cut tobacco sample C were measured to be 0 μg / mL and 0 μg / mL, respectively.

[0061] Add aflatoxin standard solution to the tobacco leaf sample without aflatoxin, then carry out sample pretreatment, extraction of aflatoxin, determination of enzyme-linked immunoassay, and calculate the recovery rate according to the added amount and measured value. The results are shown in Table 1. Judging from the recovery rate of standard solution of high, medium and low different concentration levels, the recovery rate is between 99.6%-102.0%, and the relative deviation is less than 6%, which shows that the recovery rate of this method is high and the repeatability is high. better.

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com