Synergistically modified lithium-iron-phosphate positive active material enveloped with graphene three-dimensional network and doped with metal ions and preparation method of lithium-iron-phosphate positive active material

A cathode active material, lithium iron phosphate technology, applied in battery electrodes, electrical components, circuits, etc., to reduce polarization effect, improve electrical conductivity, and excellent charge-discharge cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

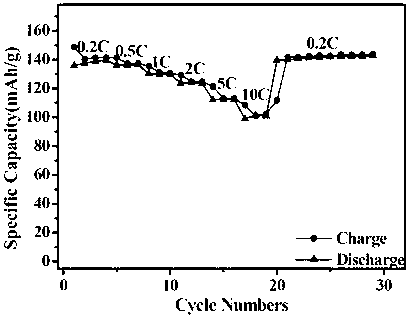

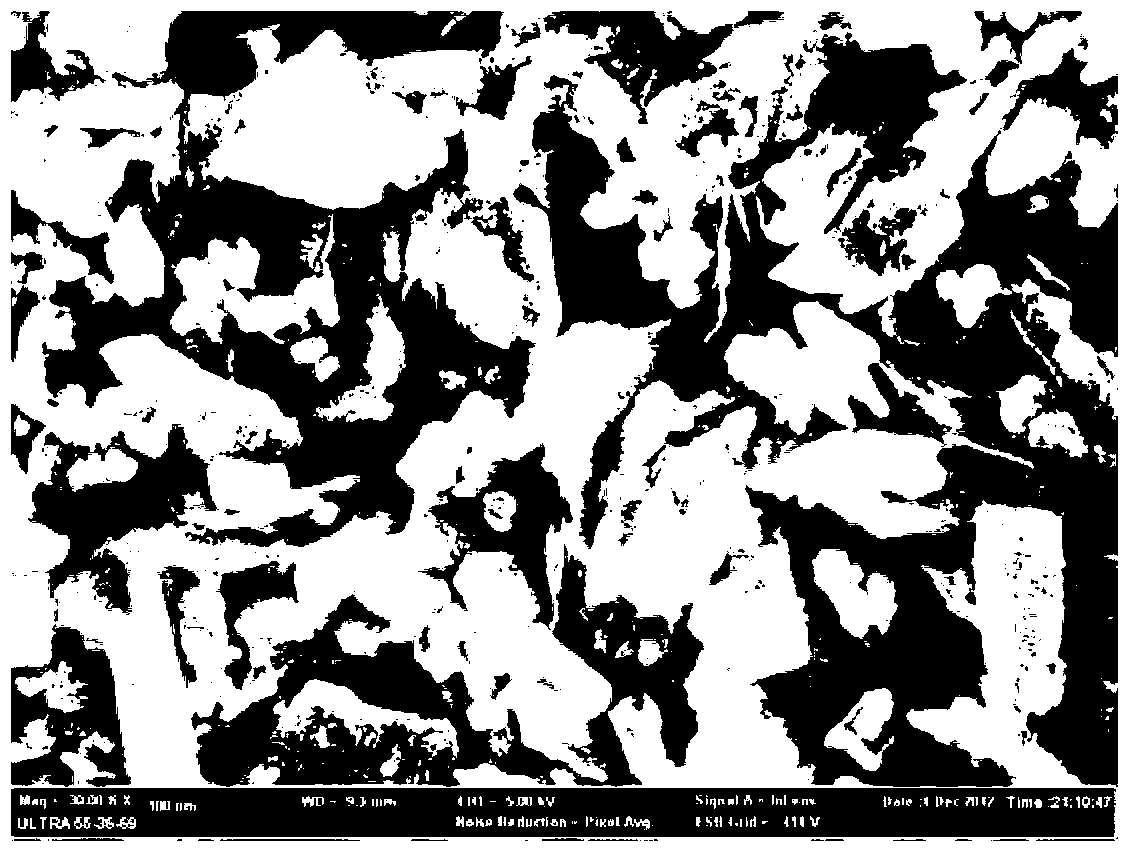

[0075] Weigh Li 2 CO 3 , FeC 2 o 4 2H 2 O, MnCO 3 , NH 4 h 2 PO 4 Mix at a molar ratio of 1:0.6:1.4:2 and ball mill for 3 hours. The resulting mixture and acetylene black were mixed and ball milled at a weight ratio of 96:4. Then heat treatment at 550°C for 24 hours in an argon atmosphere, cool to room temperature and grind to obtain metal manganese ion-doped lithium ferrous phosphate, that is, LiMn 0.7 Fe 0.3 PO 4 powder material. Weigh 0.035g graphene oxide, weigh 35ml isopropanol solution, and make a graphene oxide organic solution with a concentration of 1mg / ml; weigh 3.5gLiMn 0.7 Fe 0.3 PO 4 The powder material was dispersed into 1 mg / ml graphene oxide organic solution, stirred for 15 minutes, ultrasonicated for 30 minutes, and then rotary evaporated at 60°C to obtain graphene oxide / LiMn 0.7 Fe 0.3 PO 4 The mixture was annealed under the protection of high-purity argon at 600°C for 6 hours to obtain lithium iron phosphate modified by graphene three-dimens...

Embodiment 2

[0077] Weigh Li 2 CO 3 , FeC 2 o 4 2H 2 O, Ni(Ac) 2 4H 2 O, NH 4 h 2 PO 4 The molar ratio was 1:1.8:0.2:2, mixed and ball milled for 3 hours, and the obtained mixture was calcined at 550° C. for 8 hours under an argon atmosphere. Cool to room temperature and grind again to obtain metal nickel-doped lithium iron phosphate LiFe 0.9 Ni 0.1 PO 4 powder material. Weigh 0.01g of graphene oxide, weigh 10ml of absolute ethanol solution, and make a graphene oxide organic solution with a concentration of 1mg / ml; weigh 1g of LiFe 0.9 Ni 0.1 PO 4 The powder material was dispersed into a 1 mg / ml graphene oxide organic solution, stirred for 15 minutes, ultrasonicated for 30 minutes, and then evaporated on a rotary at 60°C to obtain graphene oxide / LiFe 0.9 Ni 0.1 PO 4 The mixture was annealed at 500° C. under the protection of high-purity argon for 8 hours to obtain lithium iron phosphate modified by graphene three-dimensional network enveloped metal nickel ions.

Embodiment 3

[0079] Weigh Li 2 CO 3 , FeC 2 o 4 2H 2 O, Co(Ac) 2 4H 2 O, NH 4 h 2 PO 4 The molar ratio was 1:1.8:0.2:2, mixed and ball milled for 3 hours, and the obtained mixture was calcined at 550° C. for 8 hours under an argon atmosphere. Cool to room temperature and grind again to obtain metal cobalt-doped lithium iron phosphate LiFe 0.9 co 0.1 PO 4 powder material. Weigh 0.07g graphene oxide, weigh 35ml aqueous solution, and make a graphene oxide organic solution with a concentration of 2mg / ml; weigh 1.5gLiFe 0.9 co 0.1 PO 4 The powder material was dispersed into a 2 mg / ml graphene oxide organic solution, stirred for 15 minutes, ultrasonicated for 30 minutes, and then evaporated at 60°C on a rotary basis to obtain graphene oxide / LiFe 0.9 co 0.1 PO 4 The mixture was annealed at 500° C. under the protection of high-purity argon for 8 hours to obtain lithium iron phosphate modified by graphene three-dimensional network enveloped metal cobalt ions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com