Inorganic nanometer particle modified polymer electrolyte and preparation method thereof

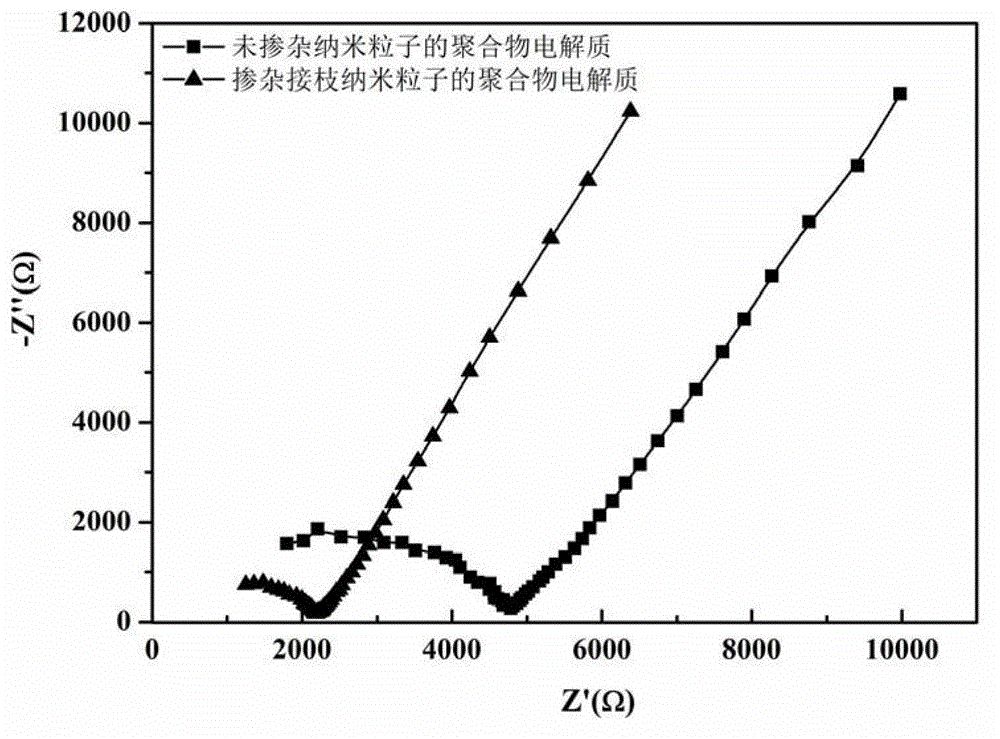

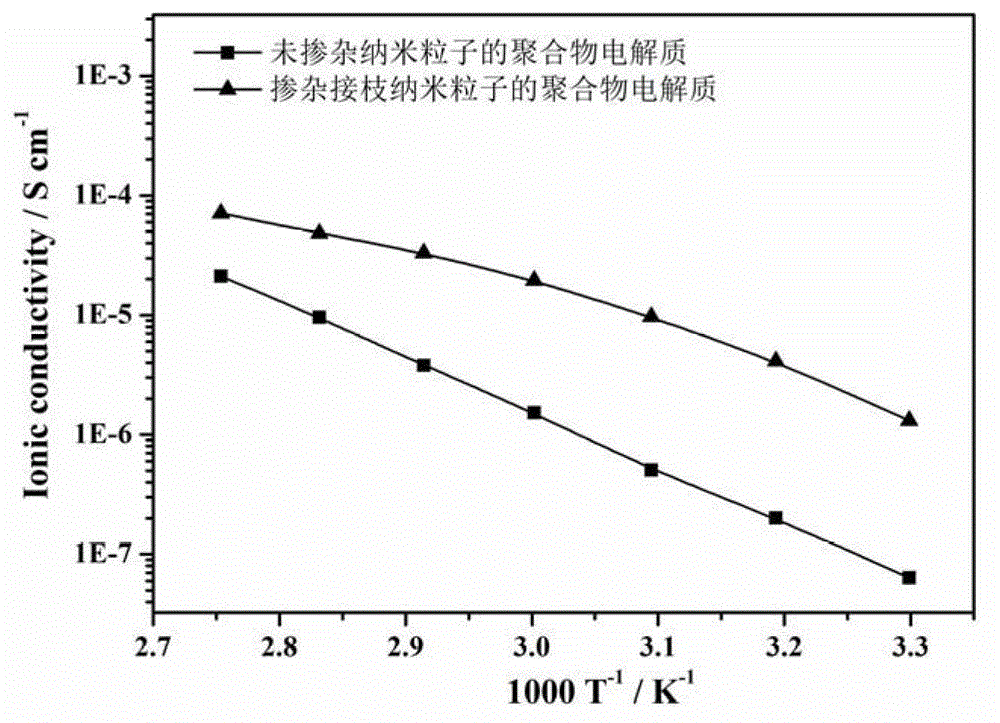

An inorganic nanoparticle and polymer technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problem of not significantly improving the mobility of PEO segments, and achieve inhibition of crystallization, high ionic conductivity, and improved ionic conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 2g nano-SiO 2 Disperse in 20ml of ammonia water with pH=8.5 to obtain nano-SiO 2 / ammonia dispersion. Add 10 mL of silane coupling agent-containing methanol solution with a mass fraction of 20% to the above solution in batches, stir at 50°C, let stand for 12 hours, filter through a microporous membrane, wash with ethanol and deionized water, and dry get nano-SiO 2 Ionic salt, wherein the structural formula of the silane coupling agent is (CH 3 O) 3 Si(CH 2 ) 5 N(CH 3 )(C 10 h 21 ) 2 Cl.

[0021] The resulting nano-SiO 2 Ionic salts are added to ethoxy-containing sulfonates with the formula C 9 h 9 -C 6 h 4 -(OCH 2 CH 2 ) 30 -O(CH 2 ) 3 SO 3K, stirred at 60°C for 12 hours. After the reaction, the reaction product was washed with deionized water, centrifuged and precipitated until the supernatant became colorless, and the precipitate was dried at 100°C to obtain nano-SiO grafted with ionic compounds containing ethoxy groups. 2 .

[0022] Nano-SiO ...

Embodiment 2

[0024] 1g nano TiO 2 Disperse in 15ml of ammonia water with PH=8 to get nano TiO 2 / ammonia dispersion. Add 7.5mL of silane coupling agent-containing methanol solution with a mass fraction of 20% to the above solution in batches, stir at 50°C, let stand for 12 hours, filter through a microporous membrane, wash with ethanol and deionized water, and dry Nano TiO 2 Ionic salt, wherein the structural formula of the silane coupling agent is (CH 3 O) 3 Si(CH 2 ) 10 N(CH 3 )(C 10 h 21 ) 2 Cl.

[0025] The resulting nano-SiO 2 Ionic salts are added to ethoxy-containing sulfonates with the formula C 9 h 9 -C 6 h 4 -(OCH 2 CH 2 ) 50 -O(CH 2 ) 3 SO 3 K, stirred at 60°C for 24 hours. After the reaction, the reaction product was washed with deionized water, centrifuged and precipitated until the supernatant became colorless, and the precipitate was dried at 100°C to obtain nano-TiO grafted with ionic compounds containing ethoxy groups. 2 .

[0026] Nano-TiO grafted...

Embodiment 3

[0028] 2g nanometer Al 2 o 3 Disperse in 25ml of ammonia water with pH=9 to obtain nano-Al 2 o 3 / ammonia dispersion. Add 5 mL of methanol solution containing 50% silane coupling agent in batches to the above solution, stir at 50°C, let stand for 12 hours, filter through a microporous membrane, wash with ethanol and deionized water, and dry get nano Al 2 o 3 Ionic salt, wherein the structural formula of the silane coupling agent is (CH 3 O) 3 Si(CH 2 ) 30 N(CH 3 )(C 10 h 21 ) 2 Cl.

[0029] The resulting nano-Al 2 o 3 Ionic salts are added to ethoxy-containing sulfonates with the formula C 9 h 9 -C 6 h 4 -(OCH 2 CH 2 ) 40 -O(CH 2 ) 3 SO 3 K, stirred at 60°C for 24 hours. After the reaction, the reaction product was washed with deionized water, centrifuged and precipitated until the supernatant became colorless, and the precipitate was dried at 100°C to obtain nano-Al grafted with ionic compounds containing ethoxy groups. 2 o 3 .

[0030] Nano-Al g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com