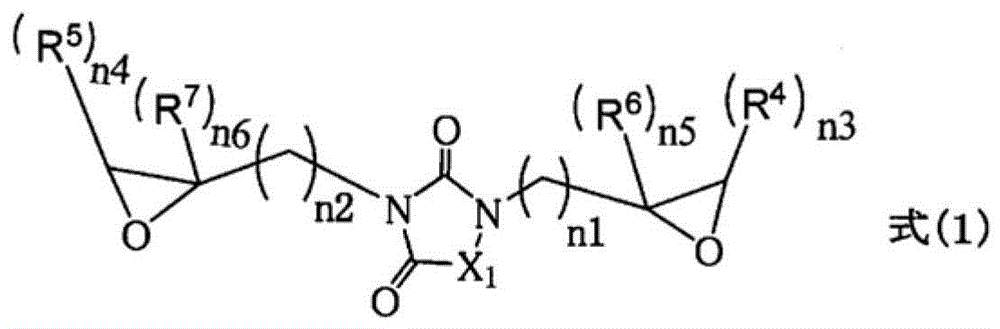

Epoxy compound with nitrogen-containing ring

A technology of epoxy compound and curable composition, which is applied in the direction of organic chemistry, can solve the problems of insufficient satisfaction and limited application range, and achieve the effects of good filling, large degree of freedom, and stable crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

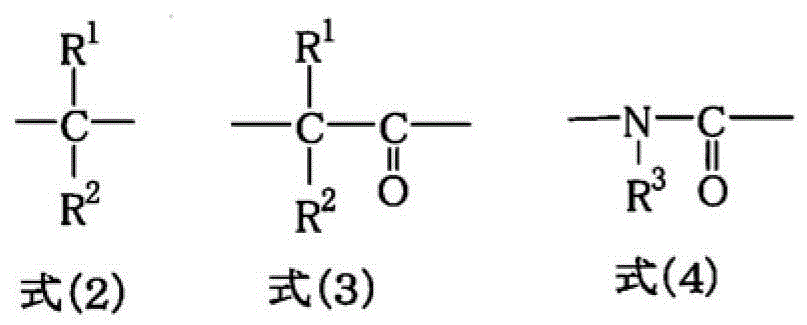

Method used

Image

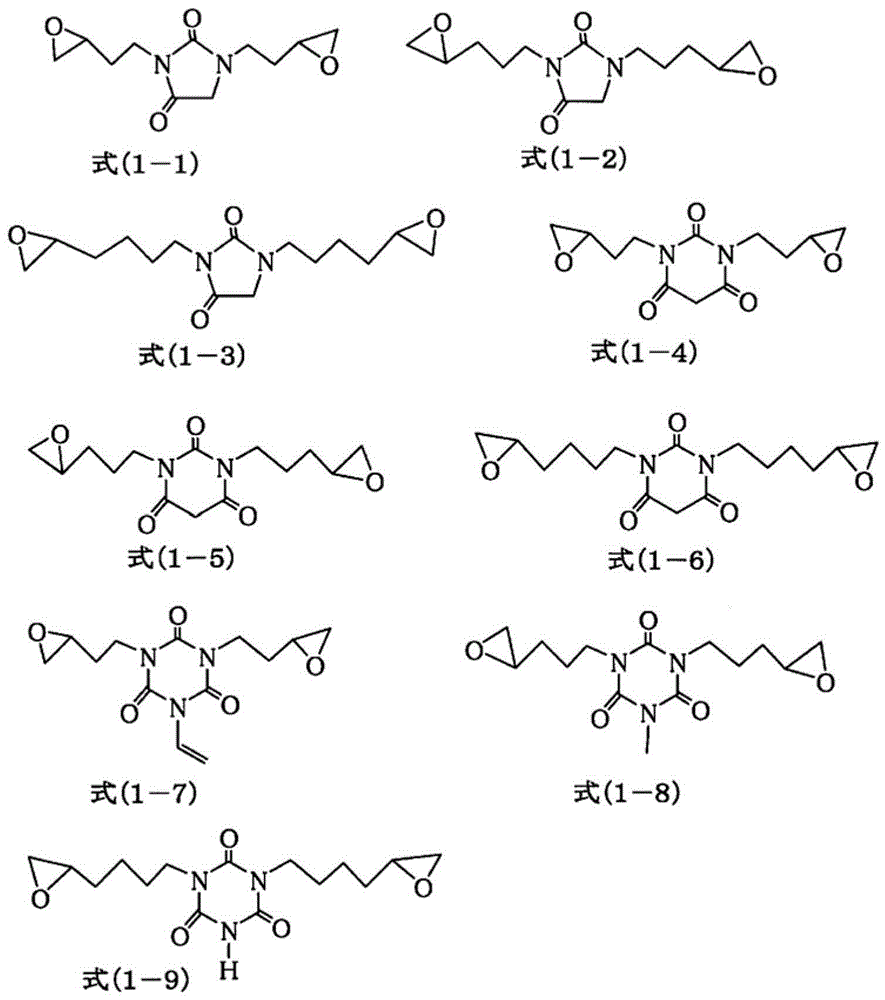

Examples

Embodiment 1

[0112]75 g of hydantoin, 750 ml of N,N-dimethylformamide, and 332 g of potassium carbonate were added to a 3 L flask, and 347 g of 5-bromopentene was added dropwise at room temperature while stirring under a nitrogen atmosphere. After completion of the dropwise addition, it was heated at an internal temperature of about 90° C. for 24 hours. After cooling the reactor at room temperature, the contents were filtered, and the obtained filtrate was washed with water three times and then concentrated to obtain a red-black liquid. This liquid was purified with a silica gel column to obtain 144 g of bis(4-pentenyl)hydantoin (red liquid, yield 81%) as an intermediate.

[0113] Next, 144 g of di(4-pentenyl)hydantoin and 6 L of dichloromethane were added to a 10 L flask, and 784 g of m-chloroperoxybenzoic acid was added while cooling to 3° C. under a nitrogen atmosphere, and stirred for 7 hours. Then, 2.8 L of 10% sodium sulfite aqueous solution was used to treat excess peracid in the r...

Embodiment 2

[0116] To 24.51 g of bis(4,5-epoxypentyl)hydantoin (epoxy value = 7.26) obtained in Example 1, MH-700 (manufactured by Shin Nippon Chemical Co., Ltd., the composition of which is 29.2 g of 4-methylhexahydrophthalic anhydride and hexahydrophthalic anhydride in a molar ratio of 70:30, stirring and defoaming for 30 minutes while heating in an oil bath at 90°C . Add 245 mg of Hikolin PX-4ET (manufactured by Nippon Chemical Industry Co., Ltd., tetrabutyldiethyl dithiophosphate), stir to defoam, and pour into a glass plate sandwiched with 3mm silicone rubber (release agent: SR Between -2410 (Toray Dow Corning Co., Ltd. treatment), pre-curing: 100° C. for 2 hours, post-curing: 150° C. for 5 hours, was cured.

[0117] The physical properties of the obtained cured product are as follows: flexural strength: 169.4MPa, flexural modulus of elasticity: 3369MPa, bending at break: 13.59mm, linear expansion rate (30-80°C): 65.5ppm / °C, Tg(TMA) : 126.5°C, transmittance (400nm): 22.0%, boiling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fatigue bending times | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com