Preparation method and application of amino-functionalized mesoporous alumina-based bifunctional adsorbent

An amino-functional, alumina-based technology, applied in chemical instruments and methods, through adsorption, separation methods, etc., can solve the problems of complex process, destroying the pore structure of precursors, and consuming large energy, achieving simple process and reducing energy consumption. , the effect of good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

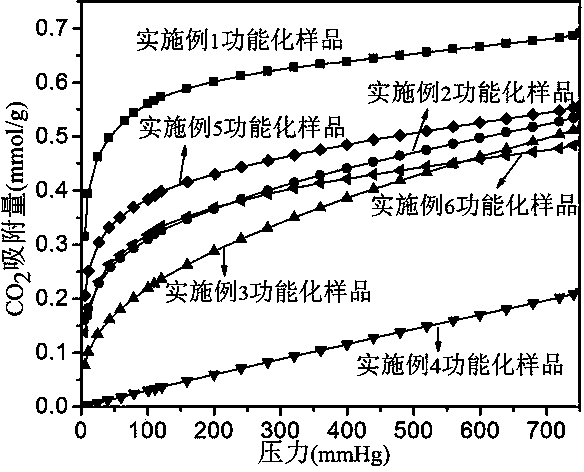

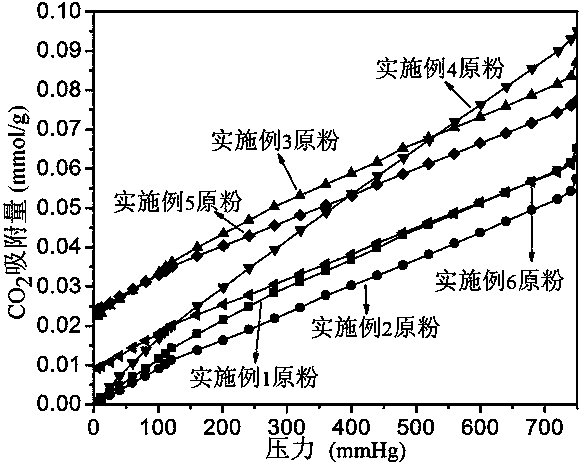

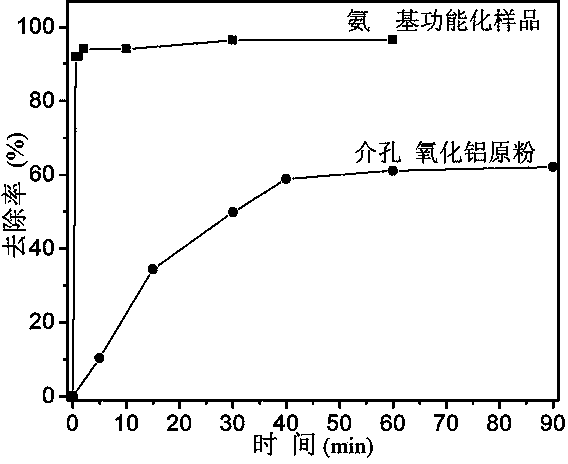

Embodiment 1

[0028]First, 3 g of P123 was dissolved in 20 ml of ethanol with thorough stirring at room temperature. Next, add 1.5ml, 65wt% concentrated nitric acid, stir and mix evenly at room temperature. Then, 3.06g of aluminum isopropoxide was added and fully dissolved under stirring at room temperature to obtain a transparent solution. Put the above transparent solution into an oven at 60°C, and evaporate at a constant temperature for 48 hours to obtain the original powder of mesoporous alumina—P123. Further, stir and dissolve 3g of tetraethylenepentamine in 20ml of ethanol at room temperature to form an ethanol solution of tetraethylenepentamine, and add 3g of mesoporous alumina—P123 raw powder, fully stir and impregnate at room temperature for 24 hours, and then centrifuge Separation, washing with ethanol and drying at 80°C for 12 hours, the amino-functionalized mesoporous alumina-based composite material was obtained. The as-prepared amino-functionalized mesoporous alumina-based c...

Embodiment 2

[0031] First, 1 g of F127 was dissolved in 20 ml of ethanol with thorough stirring at room temperature. Next, 1.5ml of 37wt% concentrated hydrochloric acid was added, and stirred and mixed evenly at room temperature. Then, 2.04 g of aluminum isopropoxide was added and fully dissolved under stirring at room temperature to obtain a transparent solution. Put the above transparent solution into an oven at 60°C and evaporate at constant temperature for 48 hours to obtain the original powder of mesoporous alumina—F127. Further, stir and dissolve 4g of triethanolamine in 100ml of ethanol at room temperature to form an ethanol solution of triethanolamine, add 2g of mesoporous alumina—F127 raw powder, fully stir and impregnate at room temperature for 12 hours, then centrifuge and wash with ethanol and drying at 100° C. for 6 h to prepare an amino-functionalized mesoporous alumina-based adsorption material. The as-prepared amino-functionalized mesoporous alumina-based composites exhib...

Embodiment 3

[0034] First, a mixture of 0.4 g of P123 and 0.4 g of F127 was dissolved in 10 ml of ethanol with thorough stirring at room temperature. Next, add 0.9ml, 37wt% concentrated hydrochloric acid, stir and mix evenly at room temperature. Then, 1 g of aluminum isopropoxide was added and fully dissolved under stirring at room temperature to obtain a transparent solution. Put the above transparent solution in an oven at 60°C, and evaporate at constant temperature for 48 hours to obtain the original powders of mesoporous alumina—P123 and F127. Further, stir and dissolve 5 g of polyethyleneimine in 50 ml of ethanol at room temperature to form an ethanol solution of polyethyleneimine, and add 1.1 g of mesoporous alumina—P123 and F127 raw powder, and fully stir and impregnate at room temperature for 6 hours. After centrifugation, ethanol washing and drying at 60°C for 12 hours in sequence, the amino-functionalized mesoporous alumina-based adsorption material was prepared. The as-prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com