Method for preparing graphene through rapid heat treatment in air atmosphere

A technology of rapid heat treatment and air atmosphere, applied in the direction of graphene, nanotechnology for materials and surface science, nanotechnology, etc., can solve the difficulty of controlling the distribution of graphene layers, the difficulty of size control and yield improvement, ultrasonic peeling production Low efficiency and other problems, achieve significant doping effect, expand heat treatment temperature range, and reduce requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: rapid heat treatment in air prepares graphene powder:

[0038] (1) The graphene precursor was prepared by the Stamdenmair method. The specific process is as follows: add 100 grams of 325 mesh natural flake graphite to 950ml HNO 3 and 1783.3mlH 2 SO 4 The mixed solution was stirred for 30 minutes, then 1100 g of sodium chlorate was added, and reacted at 25° C. for 12 hours. After suction filtration, washing, and vacuum drying at 90° C., a dark green graphene precursor was obtained.

[0039] (2) Preparation of graphene powder by rapid heat treatment in air: Take 200mg of graphene precursor and place it in a non-sealed crucible with a cover of 50mm×50mm×20mm in length×width×height, which is made of silicon carbide and has a thickness of 0.5-2mm. Quickly put it into a heat treatment furnace at 550°C, keep it warm for 30 seconds and take it out.

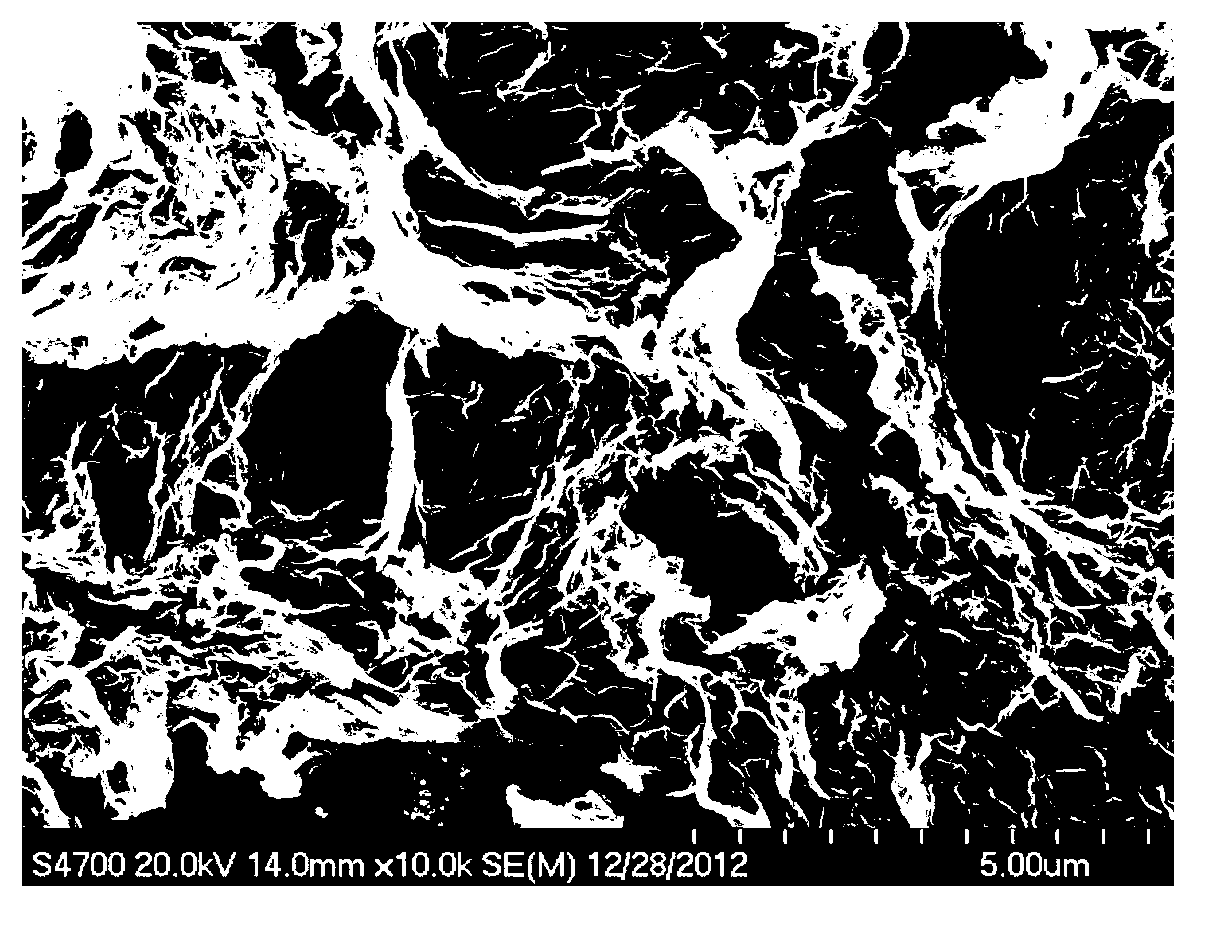

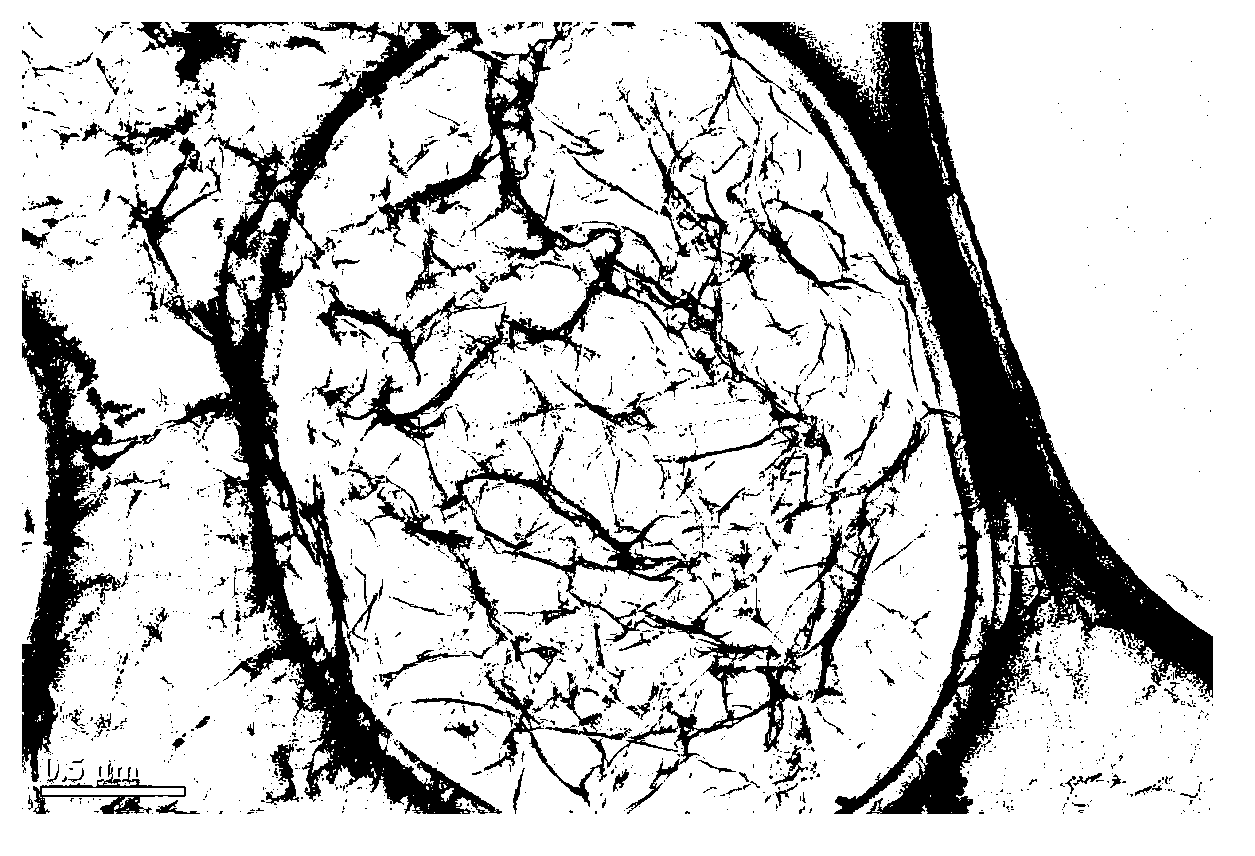

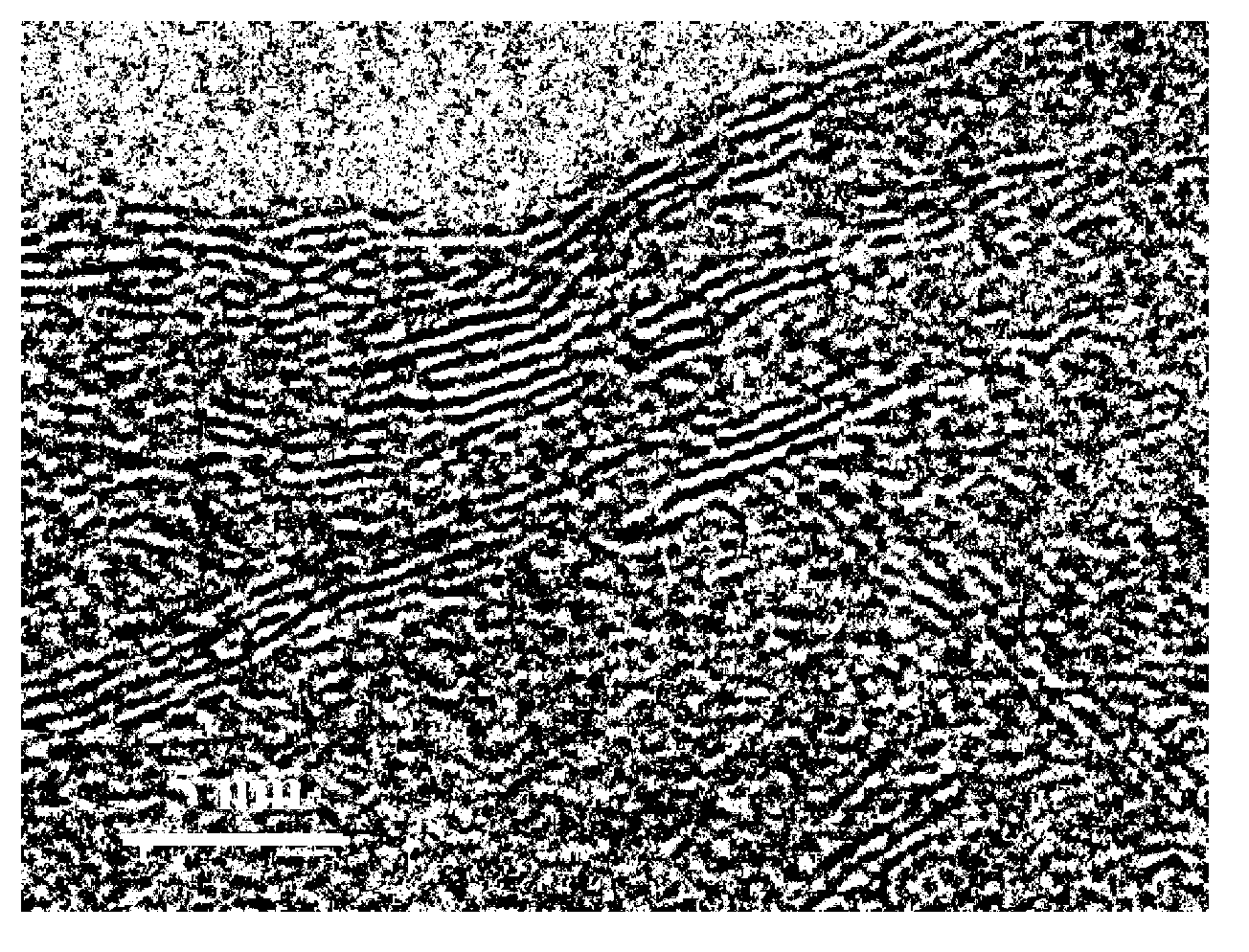

[0040] The dark green graphene precursor undergoes volume expansion after heat treatment and turns into a black...

Embodiment 2

[0043] Embodiment 2: different heat treatment temperature and different heat treatment time prepare graphene powder

[0044] (1) The preparation of the graphene precursor is the same as in Example 1;

[0045] (2) Preparation of graphene powder: Take 1g of graphene precursor respectively, place them in a non-sealed covered crucible with a length, width and height of 150mm×150mm×100mm, made of stainless steel, and a thickness of 0.5-2mm, and quickly put them into In heat treatment furnaces at 250°C, 350°C, 450°C, 550°C, 650°C, 750°C, 850°C, keep warm for 10, 30, 60, 120 seconds and take out.

[0046] Aforementioned totally 28 samples, the appearance of these samples is identical with the graphene obtained in embodiment 1, and the SEM and TEM test results are also similar. The BET test results are shown in Table 1.

[0047] Table 1 Example 2 Graphene powder BET test result

[0048]

[0049] The results show that after heat treatment at 250°C for 120 seconds, the BET is as h...

Embodiment 3

[0052] Example 3: dry mixing, preparation of doped graphene powder at the same heat treatment temperature with different urea additions

[0053] (1) The preparation of the graphene precursor is the same as in Example 1;

[0054] (2) Preparation of graphene powder: take 10g of graphene precursor and urea of different quality, the quality of urea is 0.1g, 0.3g, 0.5g, 0.7g, 1g, 2g and 3g respectively, the quality of graphene precursor and urea The ratios are 100:1, 100:3, 100:5, 100:7, 100:10, 100:20 and 100:30. Mix evenly in a mortar, then place it in a non-sealed covered crucible with a length, width and height of 400×400mm×200mm, made of stainless steel, and a thickness of 0.5-2mm, quickly put it into a heat treatment furnace at 550°C, and keep it warm for 30 seconds take out.

[0055] Figure 7 Shown is the relationship between different urea content and the BET of the obtained graphene powder. It can be seen from the figure that as the urea content increases, the BET va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Bet | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com