Waterborne fluorescent falsification-resistant ink and preparation method thereof

An anti-counterfeiting ink and fluorescence technology, applied in the field of ink, can solve the problems of low color purity, complex preparation process, toxicity, etc., and achieve the effects of high photochemical stability, broad development prospects, and high fluorescence intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

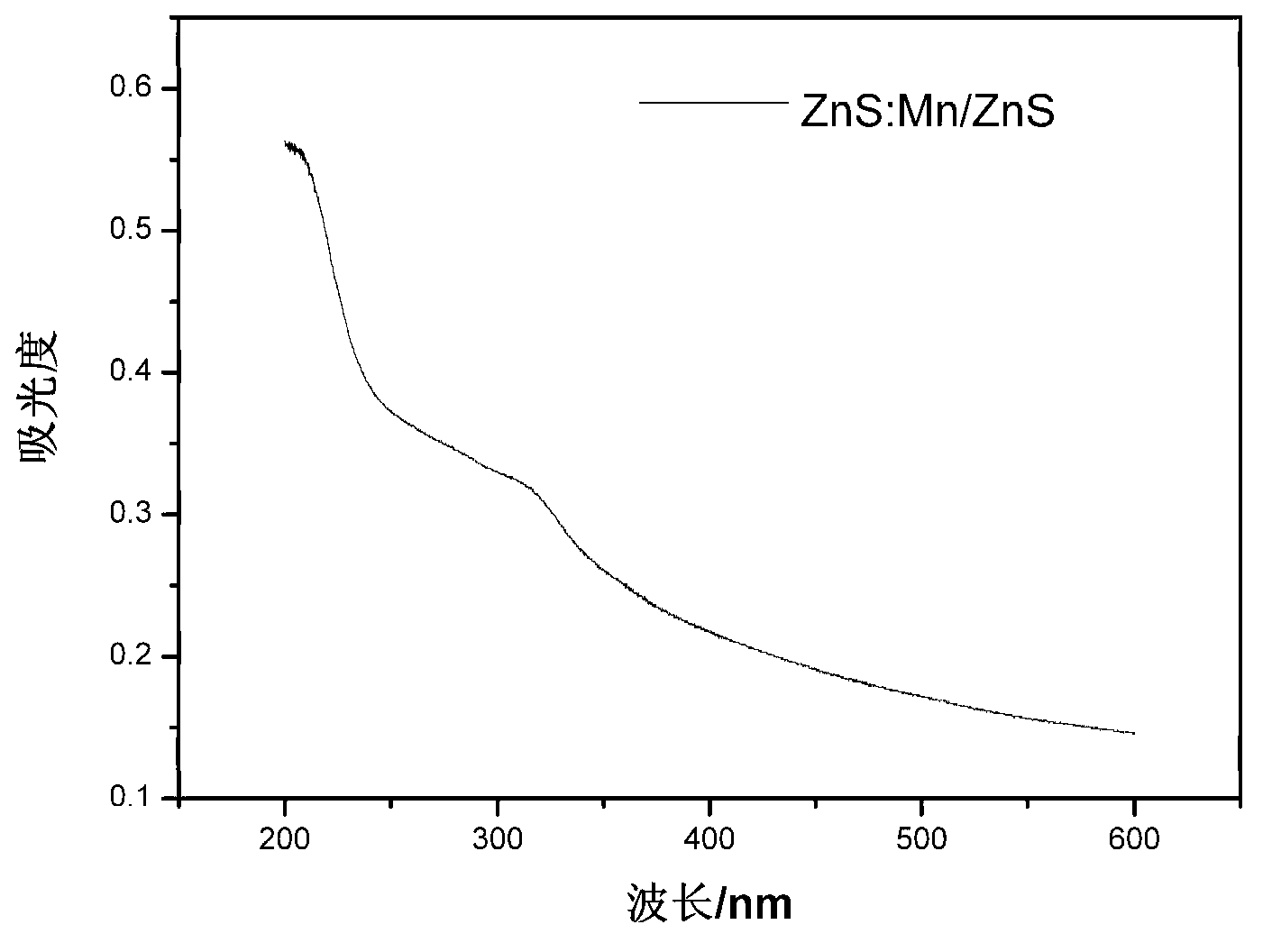

[0015] Example 1: Preparation of ZnS:Mn / ZnS quantum dots according to literature

[0016] (1) Put 5ml, 0.1mol / L zinc sulfate, 2ml, 0.01mol / L manganese chloride, 20ml, 0.1mol / L mercaptopropionic acid and 5ml, 0.1mol / L sodium sulfide in a container with N 2 Protect the reaction, the reaction temperature is room temperature 25°C, the reaction time is 30min, the obtained reaction solution is aged in the air atmosphere for 2 hours, the aging temperature is 50°C, then settled with absolute ethanol, centrifuged at high speed, and vacuum dried Obtain ZnS:Mn quantum dot solid powder.

[0017] (2) Dilute 10ml, 0.1mol / L zinc sulfate solution and 15ml, 0.1mol / L mercaptopropionic acid solution to 98ml with water, adjust the pH to 10 with 40g / L sodium hydroxide solution, and use N 2 Saturation for 30min, the mercaptopropionic acid-zinc ion complex was obtained.

[0018] (3) Dissolve the ZnS:Mn quantum dot solid powder obtained in step (1) with water to obtain 50ml of ZnS:Mn quantum dot aq...

Embodiment 2

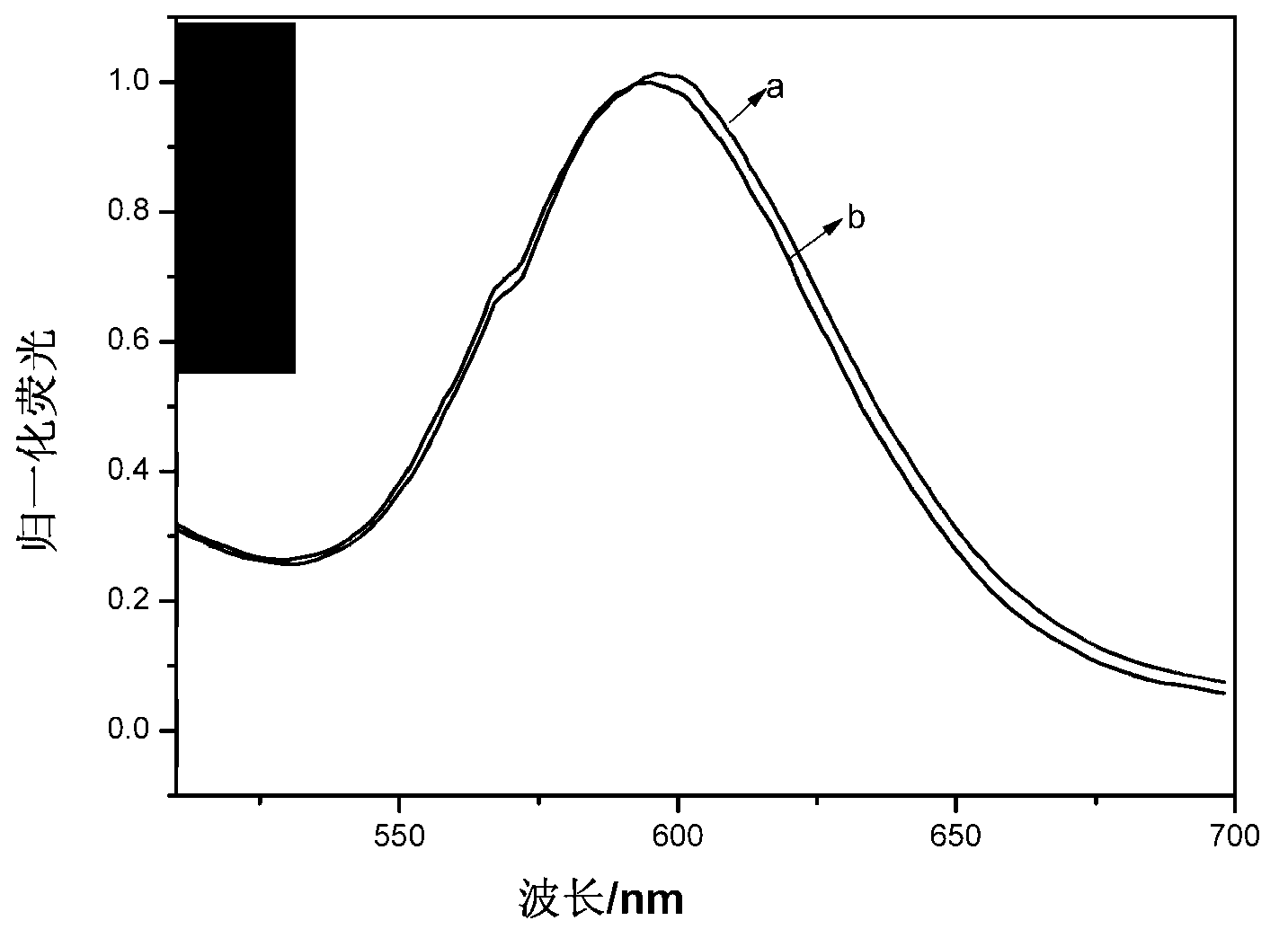

[0019] Embodiment 2: Preparation of water-based fluorescent anti-counterfeiting ink

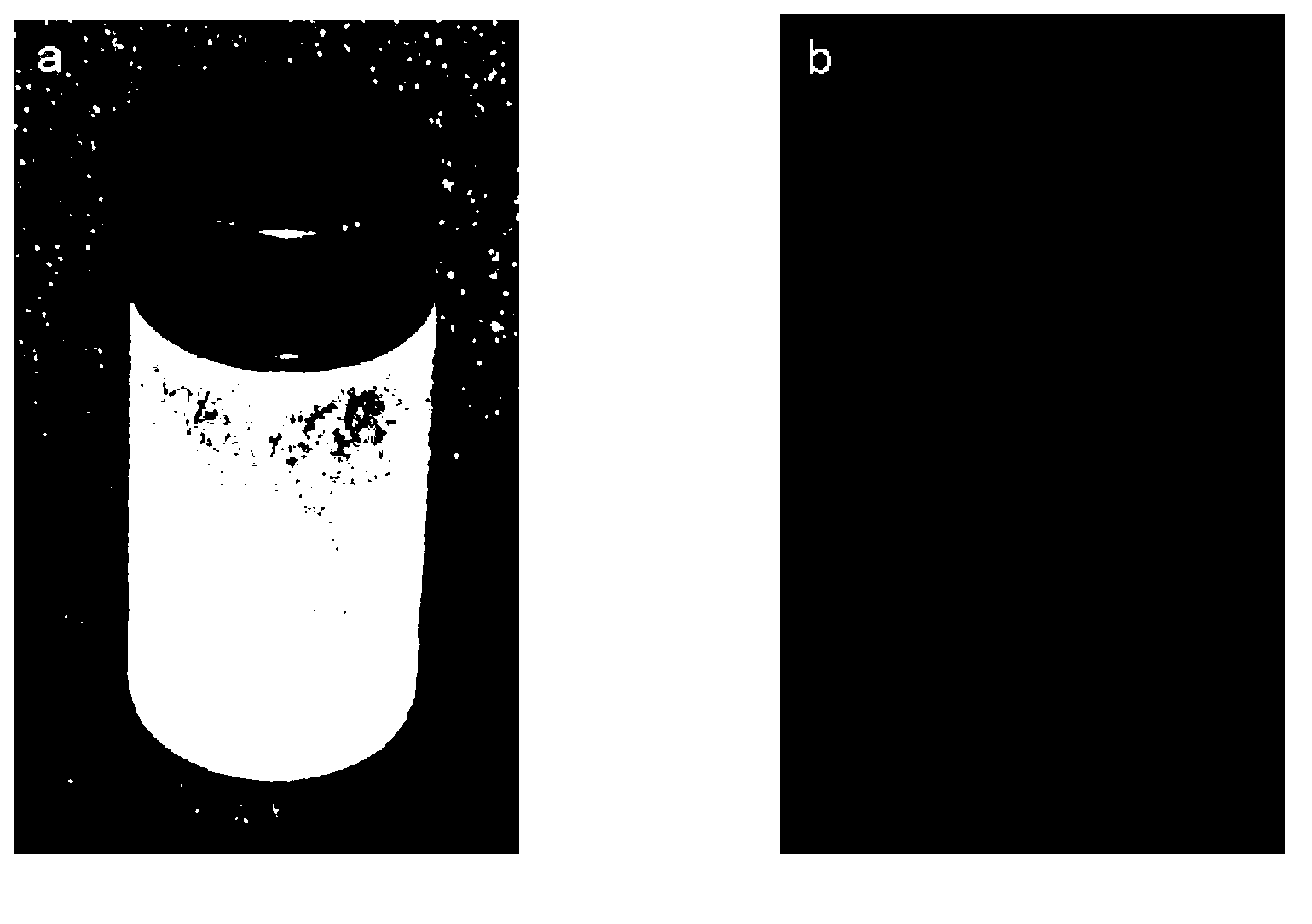

[0020] Dissolve the ZnS:Mn / ZnS quantum dot synthesized by 5g embodiment 1 with 8ml water, add 15g n-butanol, stir well, then add 0.6g sodium dodecylbenzenesulfonate, 0.3g defoamer SP-23 and 0.3g sodium polyacrylate, continue to stir for 50 minutes, add 70ml of water, stir for 30 minutes, and let stand for 1 hour to obtain a colorless water-based fluorescent anti-counterfeiting ink. Use the Cary Eclipse fluorescence spectrophotometer test to obtain the fluorescence spectrum of the ink, see figure 2 Curve b, the maximum emission wavelength of the ink is 597nm, which is consistent with the maximum emission wavelength of the ZnS:Mn / ZnS quantum dot aqueous solution. The ink is colorless under natural light conditions, see image 3 (a); reddish-orange under ultraviolet light, see image 3 (b).

[0021] The prepared ink was coated on a glass plate, it was colorless under natural light condition...

Embodiment 3

[0022] Example 3: Preparation of quantum dot water-based fluorescent anti-counterfeiting ink

[0023] Use 4ml to dissolve the ZnS:Mn / ZnS quantum dot synthesized by 2.5g embodiment 1, add 5g n-butanol, stir well, then add 0.2g sodium dodecylbenzenesulfonate, 0.1g defoamer SP-23 and 0.1g of sodium polyacrylate, continue to stir for 30 minutes, add 13ml of water, stir for 20 minutes, and let stand for 1 hour to obtain a colorless water-based fluorescent anti-counterfeiting ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com