Enteric-coated tilmicosin slow-release micro-capsule preparation and preparation method thereof

A tilmicosin and slow-release technology, which is applied in the direction of pharmaceutical formulations, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the problem of affecting animal feed intake, no slow-release function, antibacterial and growth-promoting Poor efficacy and other problems, to achieve the effect of avoiding the first pass effect of the liver, good palatability, and improving drug efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

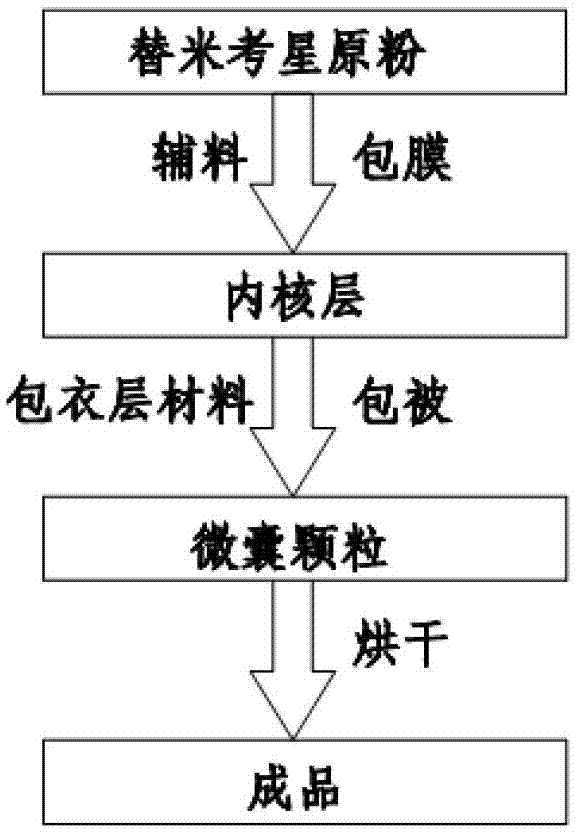

[0028] A preparation method of enteric-coated tilmicosin sustained-release microcapsule preparation, comprising the following steps:

[0029] Step 1. Add tilmicosin raw powder to the auxiliary material at a temperature of 70°C to 100°C, and coat it to form an inner core layer;

[0030] Step 2. Spray coating coating layer material on the surface of the inner core layer in the step 1 to obtain approximately spherical microcapsule particles with a diameter of 250 μm to 800 μm;

[0031] Step 3, drying the microcapsule particles prepared in step 2 to obtain the finished product.

[0032] In the present invention, the mass percentage of tilmicosin raw powder is 10% to 50%, and in this embodiment, the mass percentage of tilmicosin is preferably 10%.

[0033] Commonly used auxiliary materials are stearic acid, glyceryl monostearate, stearyl alcohol, saturated triglycerides, monoglycerides, fat powder and paraffin, in the present invention auxiliary materials are stearic acid, glycery...

Embodiment 2

[0042] Same as Example 1, the difference is:

[0043] The mass percentage of tilmicosin is 20%, and the auxiliary material is a mixture of glyceryl monostearate and fat powder, wherein the mass percentage of glyceryl monostearate is 50%, and the mass percentage of fat powder is 25%. The layer material is hypromellose phthalate, its mass percentage is 5%, and its melting temperature is 95°C.

Embodiment 3

[0045] Same as Example 1, the difference is:

[0046]The mass percentage of tilmicosin is 30%, and the auxiliary material is a mixture of glyceryl monostearate and fat powder, wherein the mass percentage of glyceryl monostearate is 40%, and the mass percentage of fat powder is 20%. The layer material is hypromellose phthalate, its mass percentage is 10%, and its melting temperature is 90°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com