Ferrate magnetic nanocomposite with core-shell structure, preparation method and application thereof

A core-shell structure, magnetic nanotechnology, applied in the field of nanomaterials, can solve the problems of difficulty in preparing nanocrystalline magnets with fine grains, too simple calculation models, and unsatisfactory effects, achieving less toxic side effects and controllable reactions. Strong, good contrast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

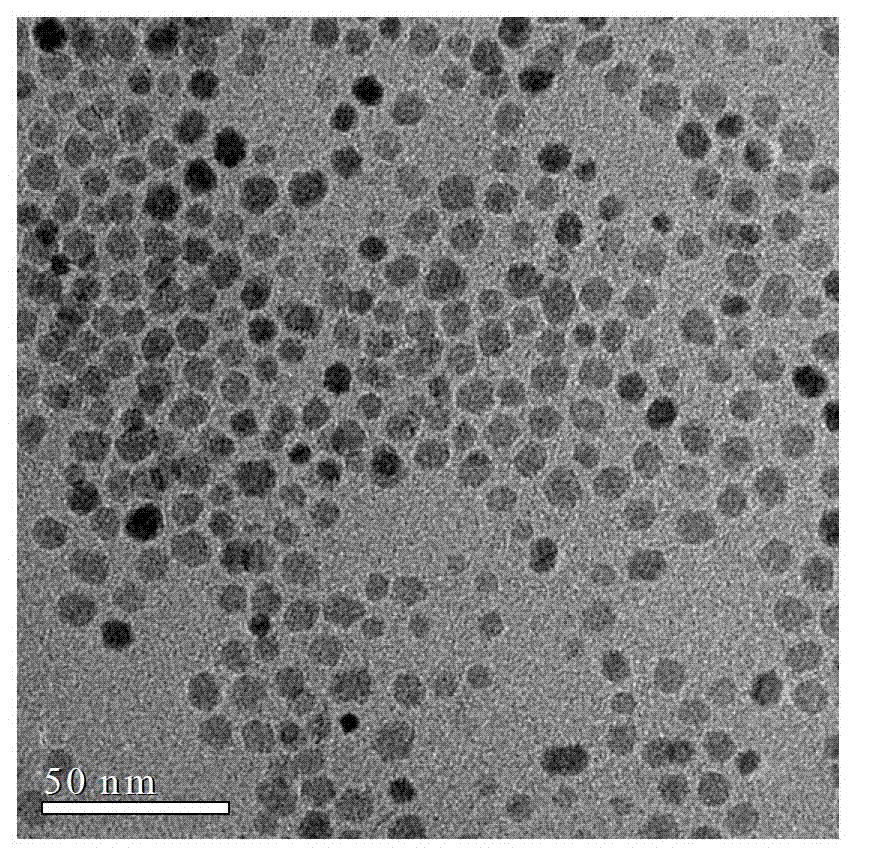

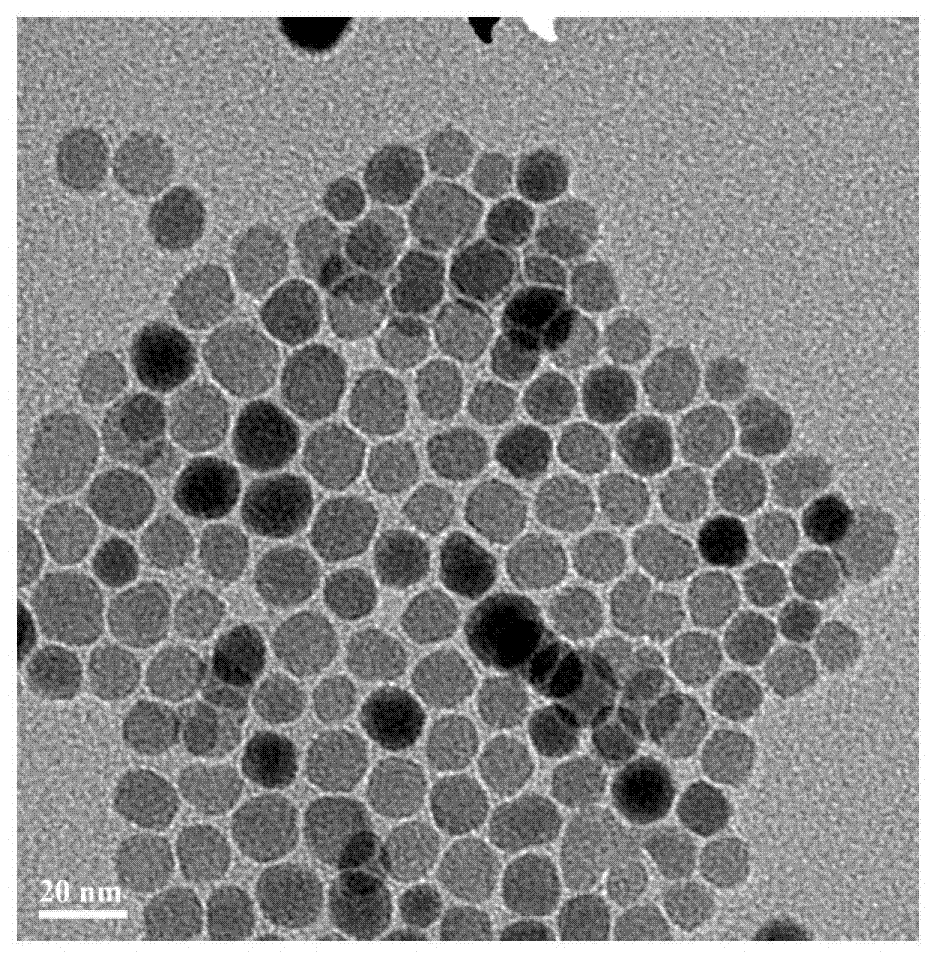

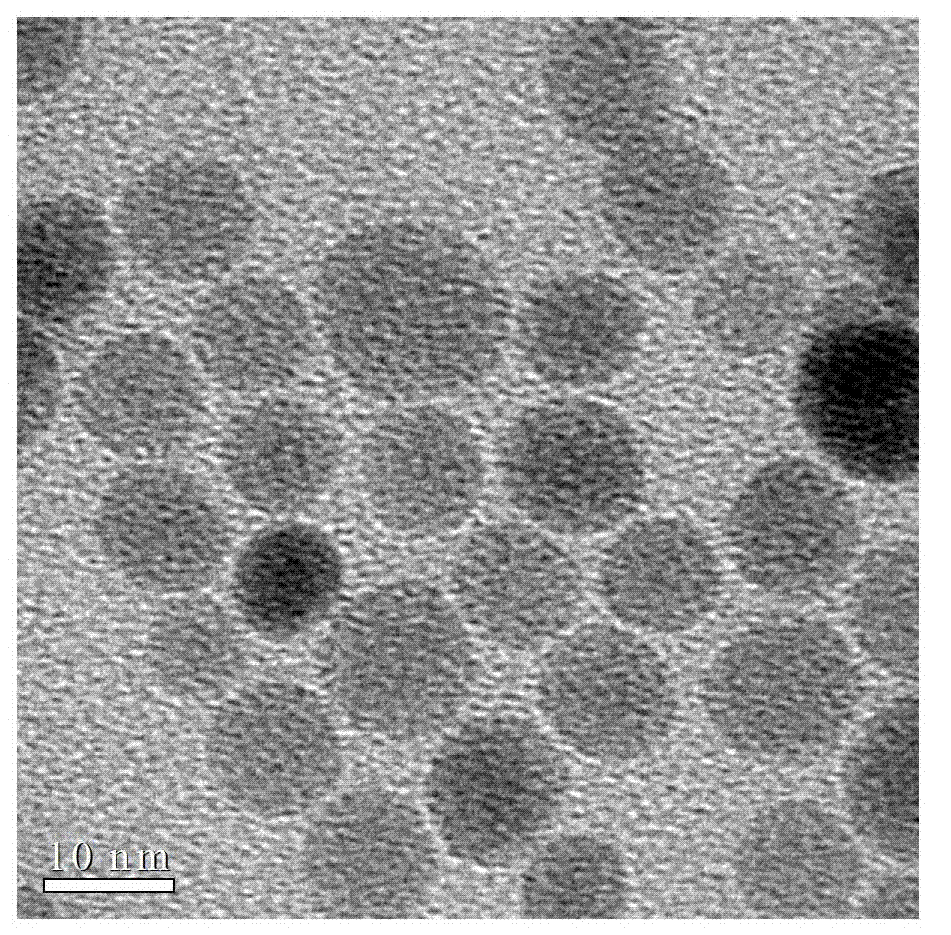

[0027] Embodiment 1 Preparation of core-shell structure manganese ferrite magnetic nanocomposite material

[0028] (1) CoFe 2 o 4 Preparation of nanoparticles:

[0029] Dissolve 1 mmol of cobalt acetylacetonate precursor and 2 mmol of iron acetylacetonate precursor in 20 mL of an organic solvent composed of oleic acid, oleylamine and benzyl ether, wherein 2 mL of oleic acid and 2 mL of oleylamine in the organic solvent , benzyl ether is 20mL, ultrasonically mixed for 20 minutes, so that the added precursor and organic solvent are mixed evenly; then add 10mmol of 1,2-hexadecanediol, and magnetically stir the mixed solution; the mixed solution is evacuated and then passed into nitrogen , the reaction system was heated up to 200° C. for 2 hours within 20 minutes and reacted for 2 hours under the protection of nitrogen, and then raised to 300° C. for 1 hour within 20 minutes. Remove the heat source, cool the system to room temperature, add 50mL of absolute ethanol to the reacti...

Embodiment 2

[0033] Example 2 Preparation of core-shell structure zinc ferrite magnetic nanocomposite material

[0034] (1) CoFe 2 o 4 The preparation method of nanoparticles is the same as in Example 1.

[0035] (2) Preparation of core-shell zinc ferrite magnetic nanocomposites:

[0036] Dissolve the precursors of 1 mmol of zinc acetylacetonate and 2 mmol of iron acetylacetonate in 20 mL of organic solvent composed of oleic acid, oleylamine and benzyl ether, wherein 2 mL of oleic acid, 2 mL of oleylamine, and benzyl ether in the organic solvent 20mL, ultrasonically mixed for 18 minutes, so that the added precursor and organic solvent were evenly mixed; then 10mmol of 1,2-hexadecanediol and the CoFe prepared in step (1) were added 2 o 4 Nanoparticles 84 mg, magnetically stirred the mixed solution; the mixed solution was evacuated and nitrogen gas was introduced, and the reaction system was under the protection of nitrogen gas, and the temperature of the mixed solution was raised to 300°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com