Hydrophilic polyvinylidene fluoride modified separation membrane and preparation method thereof

A polyvinylidene fluoride and separation membrane technology, which is applied in the direction of semipermeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of not being able to give full play to the role of modified materials and easy agglomeration, and achieve enhanced hydrophilicity and The effects of anti-pollution ability, increased contact area, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Ultrasonic disperse 0.015g carbon dioxide nanotubes and 0.135g graphene oxide in 84g N-N dimethylacetamide, add 15g polyvinylidene fluoride and 1g polyvinylpyrrolidone after 2h, and then heat and stir in a water bath at 50°C for 24h to obtain Carbon dioxide nanotubes and graphene oxide are evenly dispersed in the casting solution, and the casting solution is left to defoam for 24 hours. At room temperature, use a self-made scraper to control a certain thickness of the liquid film and scrape the film on a clean glass plate. After the casting solution was volatilized in the air for 30s, it was immersed in deionized water to solidify, and the water was changed repeatedly to remove the polyvinylidene fluoride solvent and porogen, and finally the hydrophilic polyvinylidene fluoride modified separation membrane was prepared. .

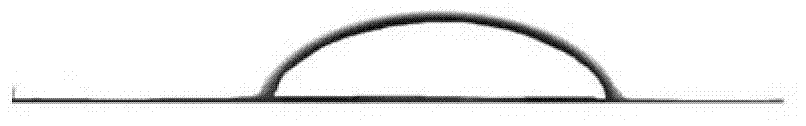

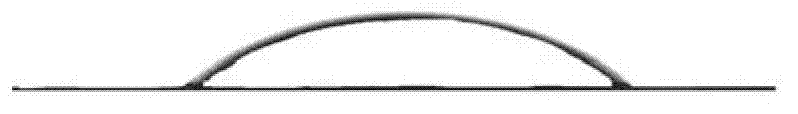

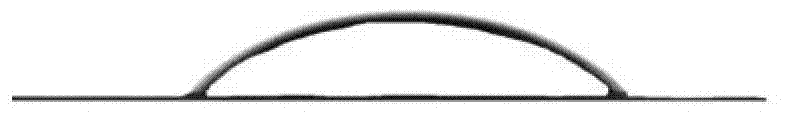

[0024] In order to better reflect the changes in the hydrophilicity of the above-mentioned modified separation membrane, the inventors vacuum-dried t...

Embodiment 2

[0026] Ultrasonic disperse 0.09g of carbon nanotubes and 0.09g of graphene oxide in 80g of dimethylformamide, add 18g of polyvinylidene fluoride and 2g of polyethylene glycol after 1h, and then heat and stir in a water bath at 50°C for 30h to obtain Carbon dioxide nanotubes and graphene oxide are evenly dispersed in the casting solution, and the casting solution is left to defoam for 24 hours. At room temperature, use a self-made scraper to control a certain thickness of the liquid film and scrape the film on a clean glass plate. After the casting solution was volatilized in the air for 30s, it was immersed in deionized water to solidify, and the water was changed repeatedly to remove the polyvinylidene fluoride solvent and porogen, and finally the hydrophilic polyvinylidene fluoride modified separation membrane was prepared. .

[0027] After testing, the hydrophilic polyvinylidene fluoride modified separation membrane provided in this example has a contact angle of 45.38° to ...

Embodiment 3

[0029] Ultrasonic disperse 0.06g carbon nanotubes and 0.24g graphene oxide in 82g N-N dimethylacetamide, add 15g polyvinylidene fluoride and 3g sodium perchlorate after 2h, then heat and stir in a water bath at 50°C for 20h Obtain a casting solution in which carbon dioxide nanotubes and graphene oxide are uniformly dispersed, and leave the casting solution to defoam for 30 hours. At room temperature, use a self-made scraper to control a certain thickness of the liquid film and scrape the film on a clean glass plate. After scraping the film, The casting solution was volatilized in the air for 30s, then immersed in deionized water to solidify, and the water was changed repeatedly to remove the polyvinylidene fluoride solvent and porogen, and finally the hydrophilic polyvinylidene fluoride modified separation membrane.

[0030] After testing, the hydrophilic polyvinylidene fluoride modified separation membrane provided in this example has a contact angle of 42.36° to water. From...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com