Method for preparing full nutritional high nitrogen type liquid flush fertilizer by monosodium glutamate waste liquid and product

A technology of monosodium glutamate waste liquid and full nutrition, which is applied in the direction of fertilizers made from biological waste, fertilization devices, applications, etc., and can solve problems such as affecting promotion, high COD content, and damage to crop roots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

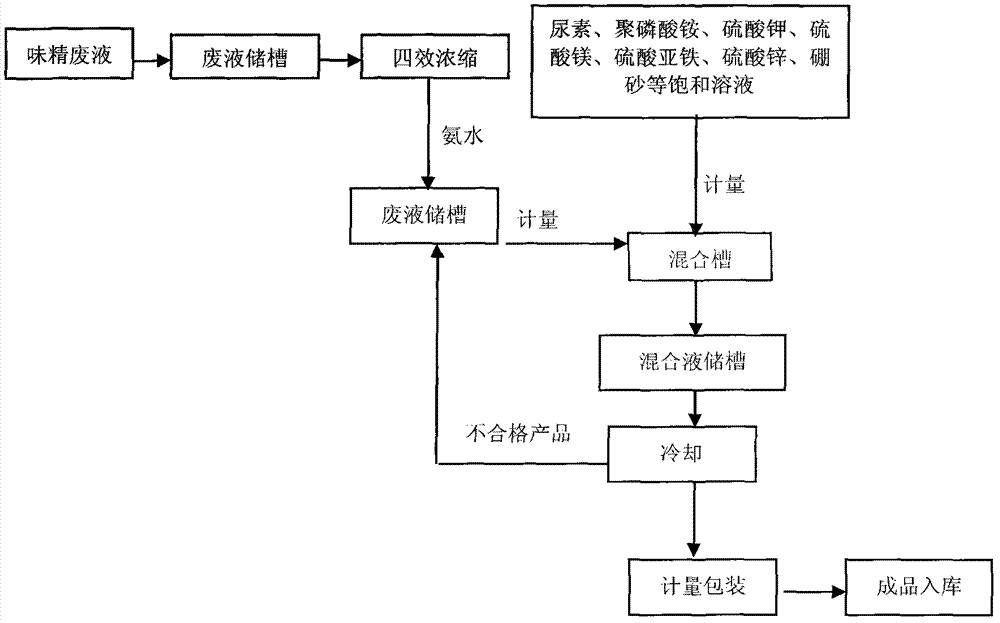

Method used

Image

Examples

example 1

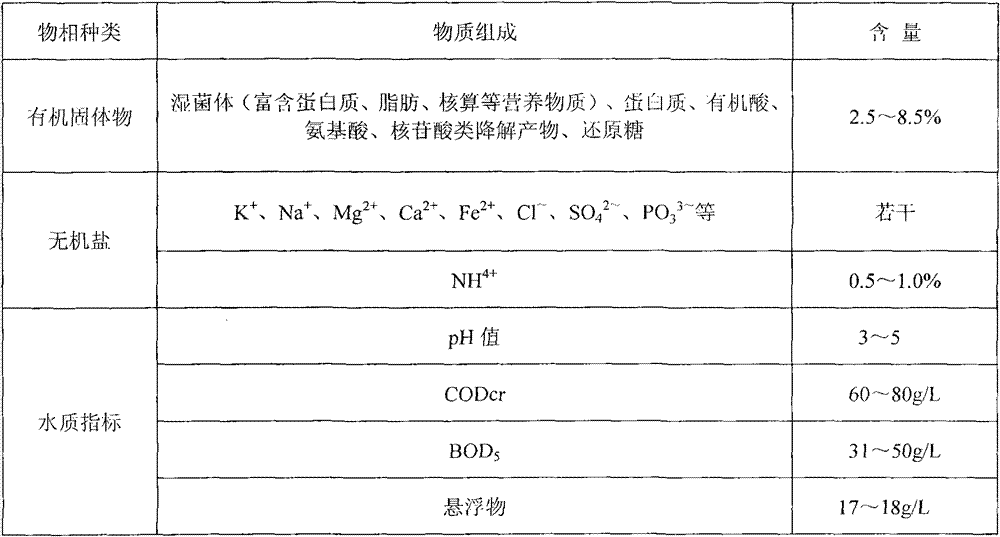

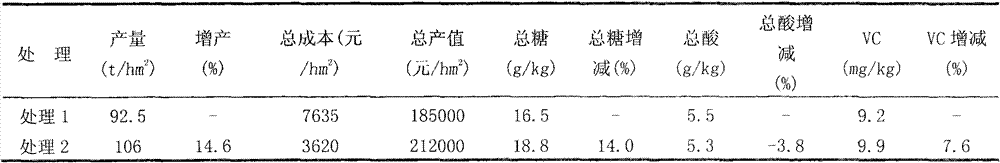

[0024] For the monosodium glutamate waste liquid collected from the monosodium glutamate factory, use the four-effect evaporation process to evaporate and concentrate until the water content is 55-70%, and obtain the monosodium glutamate waste liquid concentrated liquid. The pH value of the concentrated liquid is determined to be 3.0-4.5, and the nitrogen content is 5.0-8.5 %. Take 50 parts of monosodium glutamate concentrated waste liquid, 10 parts of ammonia water, 10 parts of ammonium polyphosphate saturated solution, 10 parts of urea saturated solution, and 5 parts of potassium sulfate saturated solution, mix the above saturated solutions, stir for 20 minutes, and add the volume percentage of 2 % magnesium sulfate saturated solution, volume percentage is 2% zinc sulfate saturated solution, volume percentage is 2% ferrous sulfate saturated solution, volume percentage is 1% borax saturated solution, stirring for 30 minutes. Fill the mixed liquid processed through the above s...

example 2

[0026] For the monosodium glutamate waste liquid collected from the monosodium glutamate factory, use the four-effect evaporation process to evaporate and concentrate until the water content is 55-70%, and obtain the monosodium glutamate waste liquid concentrated liquid. The pH value of the concentrated liquid is determined to be 3.0-4.5, and the nitrogen content is 5.0-8.5 %. Take 50 parts of monosodium glutamate concentrated waste liquid, 10 parts of ammonia water, 10 parts of ammonium polyphosphate saturated solution, 15 parts of urea saturated solution, and 6 parts of potassium sulfate saturated solution, mix the above saturated solutions, stir for 20 minutes, and add the volume percentage of 2 % magnesium sulfate saturated solution, 2% zinc sulfate saturated solution by volume, 1% ferrous sulfate saturated solution by volume, 1% borax saturated solution by volume, and stirred for 30 minutes. Fill the mixed liquid processed through the above steps directly. After testing,...

example 3

[0028] For the monosodium glutamate waste liquid collected from the monosodium glutamate factory, use the four-effect evaporation process to evaporate and concentrate until the water content is 55-70%, and obtain the monosodium glutamate waste liquid concentrated liquid. The pH value of the concentrated liquid is determined to be 3.0-4.5, and the nitrogen content is 5.0-8.5 %. Take 60 parts of monosodium glutamate concentrated waste liquid, 10 parts of ammonia water, 10 parts of ammonium polyphosphate saturated solution, 5 parts of urea saturated solution, and 6 parts of potassium sulfate saturated solution, mix the above saturated solutions, stir for 25 minutes and add the volume percentage of 2 % magnesium sulfate saturated solution, volume percentage is 1% zinc sulfate saturated solution, volume percentage is 2% ferrous sulfate saturated solution, volume percentage is 2% borax saturated solution, stirring for 25 minutes. Fill the mixed liquid processed through the above ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com