High temperature-resistant damp heat-resistant polytriazole resin adhesive and preparation method and application

A polytriazole resin and adhesive technology, applied in the field of fine chemicals, can solve the problems of poor heat resistance, low glass transition temperature, etc., and achieve the effects of low moisture absorption rate, high glass transition temperature, and small thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

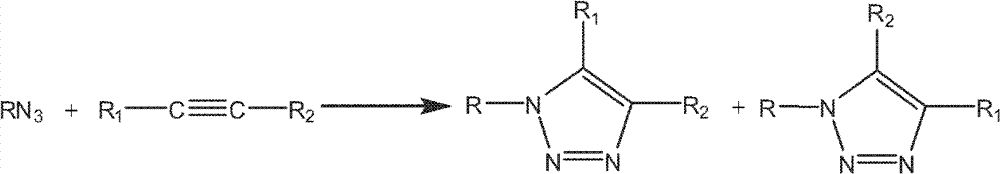

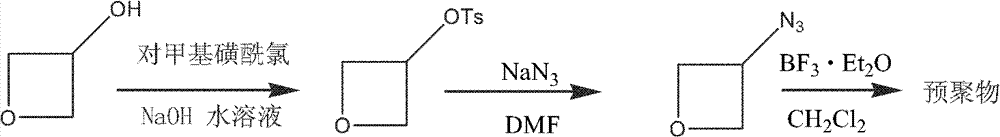

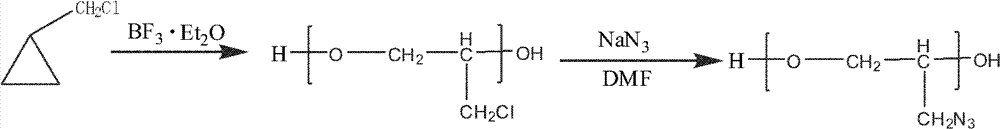

Method used

Image

Examples

Embodiment 1

[0038] A 2 B 4 Preparation and Properties of Type Polytriazole Resin Hot Melt Adhesive

[0039] (1) 1, the synthesis of 4-diazidomethylbenzene (A 2 )

[0040] Add p-dichloromethylbenzene (0.05mol), NaN 3 (0.15mol), toluene (20mL) and N,N-dimethylformamide (20mL), heated to 70~75°C under stirring, and reacted at constant temperature for 3h. After the reaction, the reaction product was cooled to room temperature and poured into 200mL In deionized water, stand overnight under freezing conditions to precipitate white flaky crystals, filter, wash the filter cake with deionized water, and dry to obtain a white powdery solid with a yield of 90%. Melting point: 27~29℃; FT-IR (KBr, v, cm -1 ): 2089 (-N 3 stretching vibration); 1 H-NMR (CDCl 3 , TMS) δ: 7.33 (s, 4H, ArH), 4.35 (s, 4H, -CH 2 ).

[0041] (2) N, N, N', the preparation of N'-tetrapropargyl-4,4'-diamino-diphenylmethane (B 4 )

[0042] Under nitrogen atmosphere conditions, 4.90g of diaminodiphenylmethane, 10.4g of...

Embodiment 2

[0056] A 2 B 4 Preparation and Properties of Type Polytriazole Resin Solution Adhesive

[0057] (1)A 2 B 4 Preparation of Type Polytriazole Solution Adhesive

[0058] Mix 7.52g (0.040mol) of 1,4-diazidemethylbenzene with 6.96g (0.020mol) of N,N,N',N'-tetrapropargyl-4,4'-diamino-diphenylmethane Add 6.21 g of acetone into a four-neck round bottom flask, slowly heat up to 60° C., stir and react for 2 hours to obtain a reddish-brown resin solution, and add acetone to make the concentration of the solution reach 50 wt%.

[0059] (2) Bonding and curing

[0060] The metal surface to be bonded is pretreated according to the conventional method, and the polytriazole resin solution is evenly coated on the bonding area of the metal test piece (copper, aluminum, pig iron) (the area is 25 × 12.5mm 2 ), place the metal test piece at 70°C for 20 minutes to volatilize the solvent, bond another metal test piece to the test piece with adhesive, and apply a pressure of 5kg on the bonding...

Embodiment 3

[0062] A' 2 B 4Preparation and Properties of Type Polytriazole Resin Hot Melt Adhesive

[0063] (1) Synthesis of diazide methyl biphenyl (A' 2 )

[0064] Add 12.65 g (0.05 mol) of p-diphenyl benzyl chloride, NaN 3 9.75g (0.15mol), toluene (20mL) and DMF (20mL), heated to 70~75°C under stirring, and reacted at constant temperature for 3h. After the reaction, cooled the reaction product to room temperature, poured it into 200mL deionized water, and White flaky crystals were precipitated after standing overnight under the conditions, filtered, the filter cake was washed with deionized water, and dried to obtain a white powdery solid with a yield of 90.0% and a melting point of 68-71°C. 1 H-NMR (CDCl 3 / TMS) δ: 4.40 (s, 2H, -CH 2 ), 7.39-7.42 (d, 2H, ArH), 7.60-7.63 (d, 2H).

[0065] (2)A' 2 B 4 Preparation of Type Polytriazole Hot Melt Adhesive

[0066] After mixing 5.28g (0.020mol) of diazidemethylbiphenyl with N,N,N',N'-tetrapropargyl-4,4'-diamino-diphenylmethane 3.48...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com