Method of improving light current of silicon thin film solar cell

A solar cell, silicon thin film technology, applied in circuits, electrical components, sustainable manufacturing/processing, etc., can solve the problems of carrier surface recombination, difficult control, complex process, etc., to improve photocurrent, low cost, flexible matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

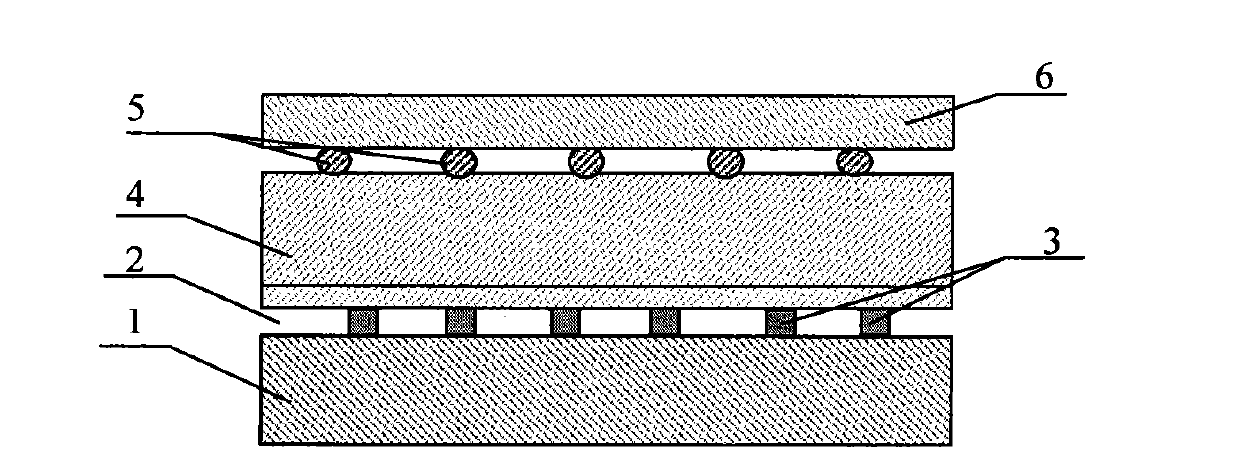

[0014] Such as figure 1 , using transparent conductive glass (1) as the substrate, depositing the copper island film in the magnetron sputtering vacuum chamber, the specific process parameters are as follows: the background vacuum is 5*10 -4 Pa or higher, the purity of the copper target is above 99.99%, the gas is argon with a purity of 99.999%, the deposition pressure is between 0.8Pa-3Pa, the substrate temperature is 150°C-200°C, and the deposition time is 10S-30S. The film thickness is 15nm-30nm. In-situ annealing is carried out on the prepared copper island film in the same vacuum chamber, the annealing temperature is maintained at 300°C-400°C, and the annealing time is 1.5-3 hours to form a copper nanoparticle array (2), the size of which is between 15- Between 30nm, its shape can be spherical, ellipsoidal, cylindrical or prismatic, and the particle distance can be increased by prolonging the annealing time as required. Vacuum for 10-20 minutes after annealing to make t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com