Tin alloy membrane electrode and application thereof

A thin-film electrode and tin alloy technology, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problems of complex process, unfavorable industrialization, and high energy consumption, and achieve the effect of simple preparation process, stable performance, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

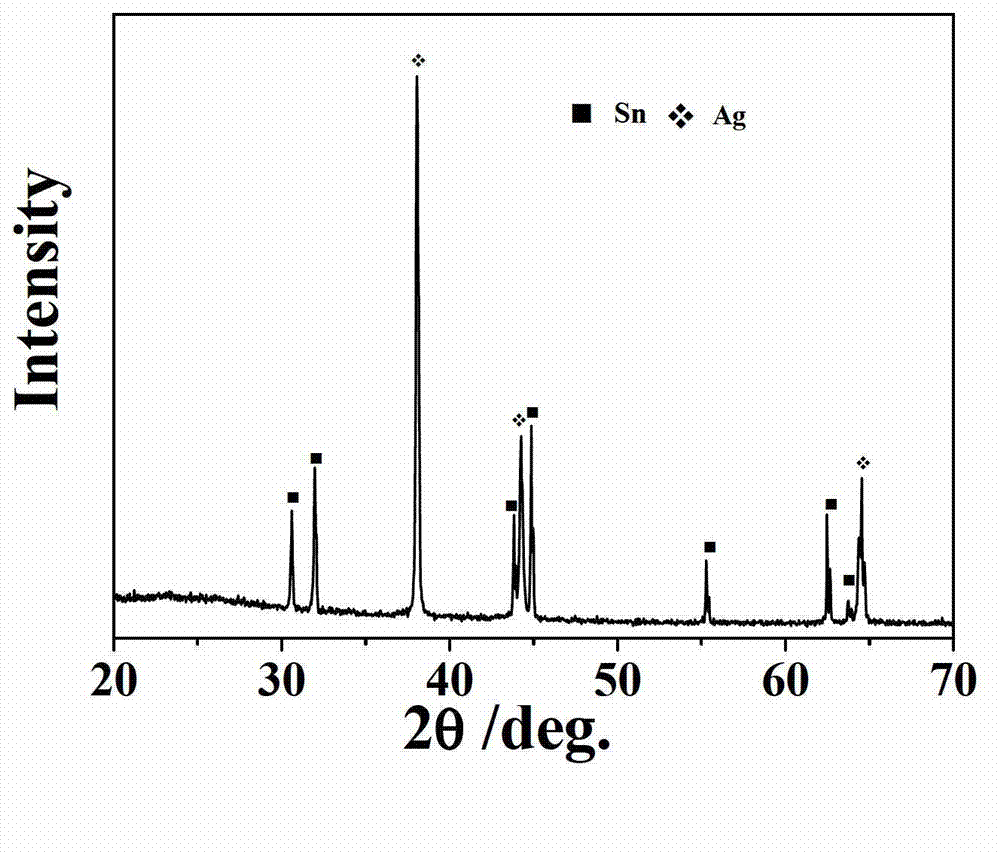

[0039] Add 100ml of distilled water to a 250ml beaker and add concentrated sulfuric acid dropwise to control the pH of the plating solution at 1.0, then add 4g of citric acid, 8g of sodium hypophosphite, 4g of thiourea, 0.03mol of stannous sulfate, and 0.06g of silver nitrate, and heat the plating solution to 30-40°C. 1cm 2 The copper foil was corroded with 0.5 mol / L sulfuric acid for 10 minutes, then washed with distilled water, dried in vacuum, put into the plating solution, the reaction time was 60s, and dried to obtain the product.

[0040] The test battery is composed of tin thin film negative electrode, metal lithium sheet and Asahi Kasei PP / PE / PP diaphragm, and the electrolyte is 1 mol / L LiPF6 / (m(EC):m(DMC)=1:1). Then assemble it into a 2032 type button half battery. The electrochemical test was carried out on the Land battery test system (CT 2001A), the voltage range was 0.01-1.5 V, and the current density was 0.1 mA / cm 2 .

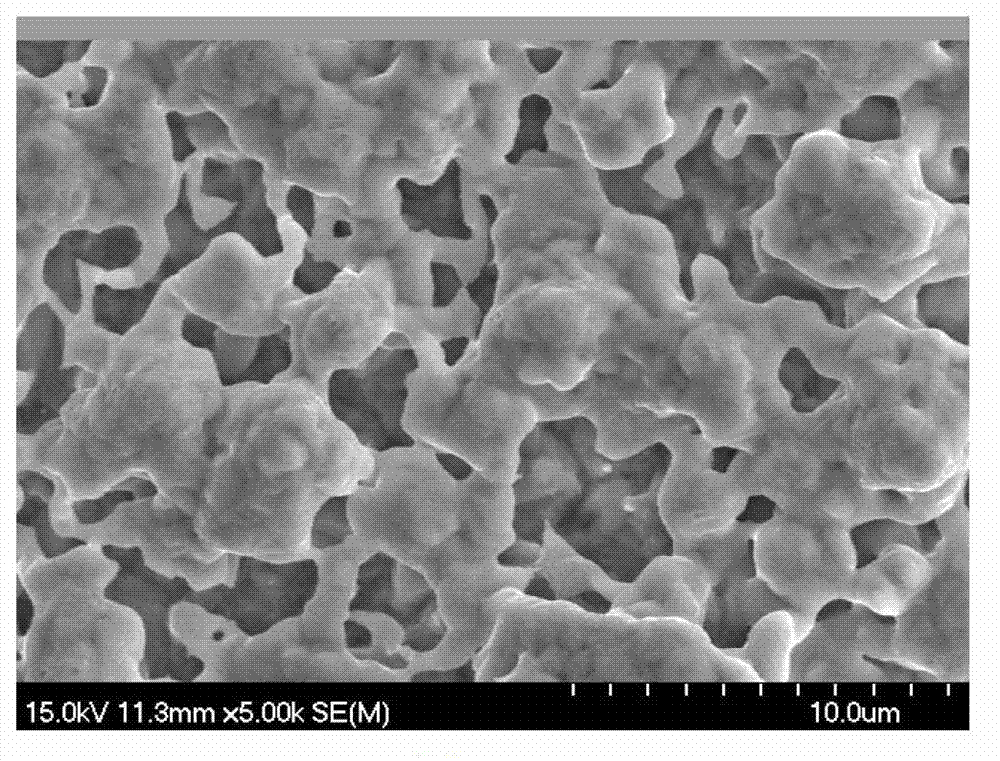

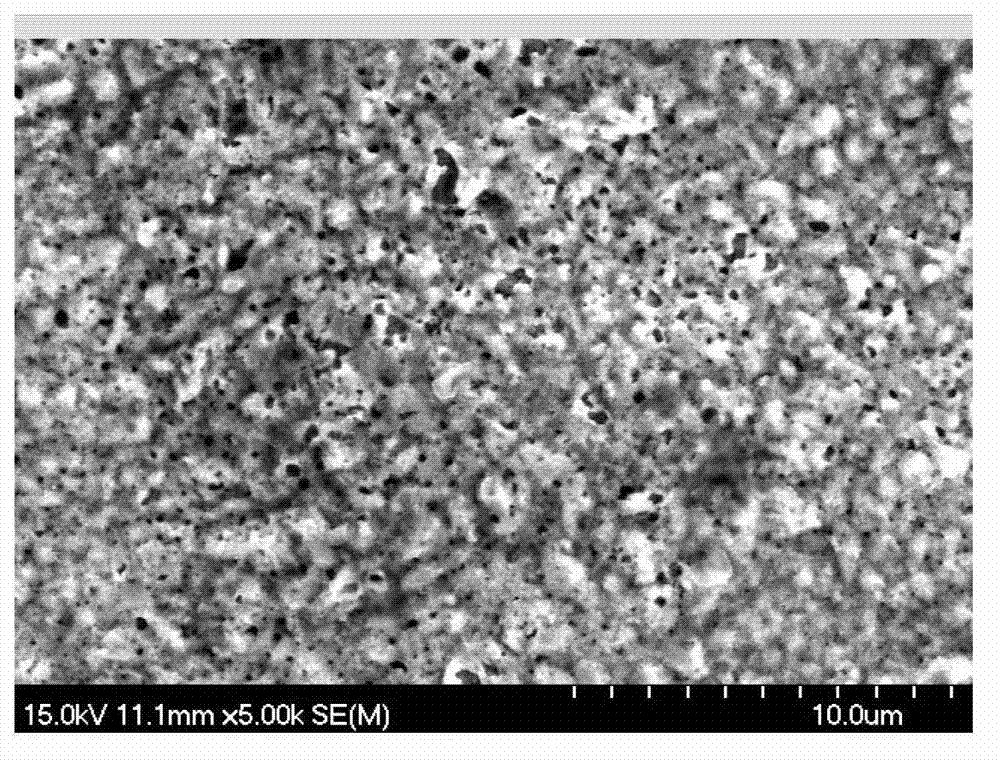

[0041] Scanning electron microscopy is ...

Embodiment 1-2

[0044]Add 100ml of distilled water to a 250ml beaker and add concentrated sulfuric acid dropwise to control the pH of the plating solution at 1.0, then add 4g of citric acid, 8g of sodium hypophosphite, 4g of thiourea, 0.02mol of stannous sulfate, and 0.04g of silver nitrate, and heat the plating solution to 30-40°C. 1cm 2 The copper foil was corroded with 0.5 mol / L sulfuric acid for 10 minutes, then washed with distilled water, dried in vacuum, put into the plating solution, the reaction time was 60s, and dried to obtain the product.

[0045] The test battery is composed of tin thin film negative electrode, metal lithium sheet and Asahi Kasei PP / PE / PP diaphragm, and the electrolyte is 1 mol / L LiPF6 / (m(EC):m(DMC)=1:1). Then assemble it into a 2032 type button half battery. The electrochemical test was carried out on the Land battery test system (CT 2001A), the voltage range was 0.01-1.5 V, and the current density was 0.1 mA / cm 2 .

Embodiment 1-3

[0047] Add 100ml of distilled water to a 250ml beaker and add concentrated sulfuric acid dropwise to control the pH of the plating solution at 1.0, then add 4g of citric acid, 8g of sodium hypophosphite, 4g of thiourea, 0.04mol of stannous sulfate, and 0.08g of silver nitrate, and heat the plating solution to 30-40°C. 1cm 2 The copper foil was corroded with 0.5 mol / L sulfuric acid for 10 minutes, then washed with distilled water, dried in vacuum, put into the plating solution, the reaction time was 60s, and dried to obtain the product.

[0048] The test battery is composed of tin thin film negative electrode, metal lithium sheet and Asahi Kasei PP / PE / PP diaphragm, and the electrolyte is 1 mol / L LiPF6 / (m(EC):m(DMC)=1:1). Then assemble it into a 2032 type button half battery. The electrochemical test was carried out on the Land battery test system (CT 2001A), the voltage range was 0.01-1.5 V, and the current density was 0.1 mA / cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com