Graphite/manganous oxide composite electrode material and preparation method thereof

A manganese oxide composite material, composite electrode technology, applied in battery electrodes, nanotechnology for materials and surface science, circuits, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

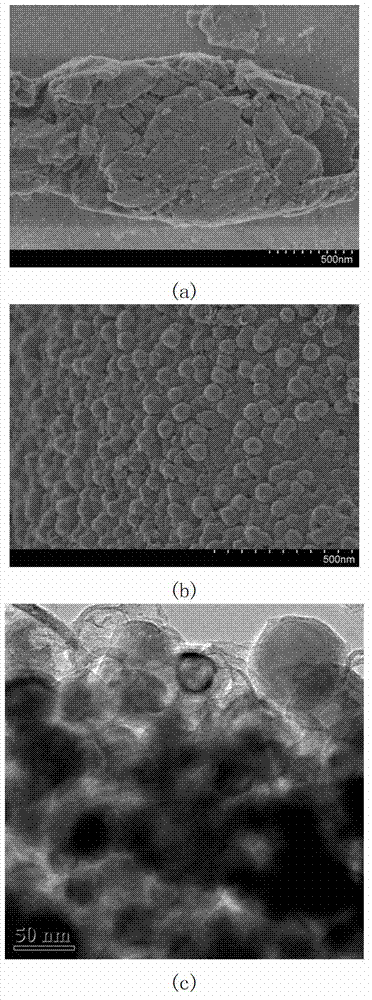

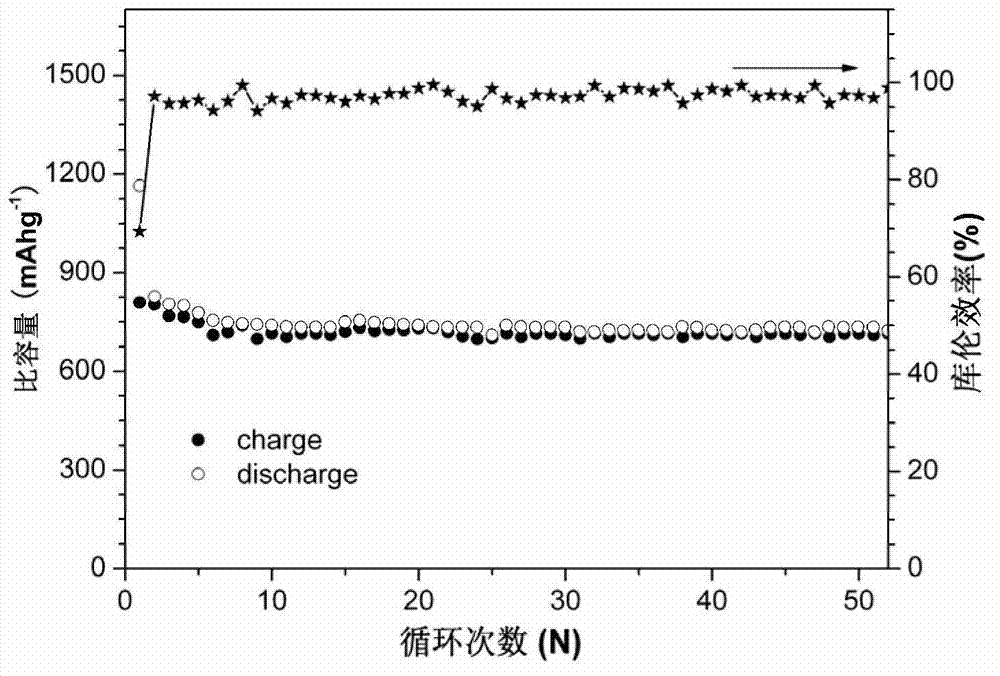

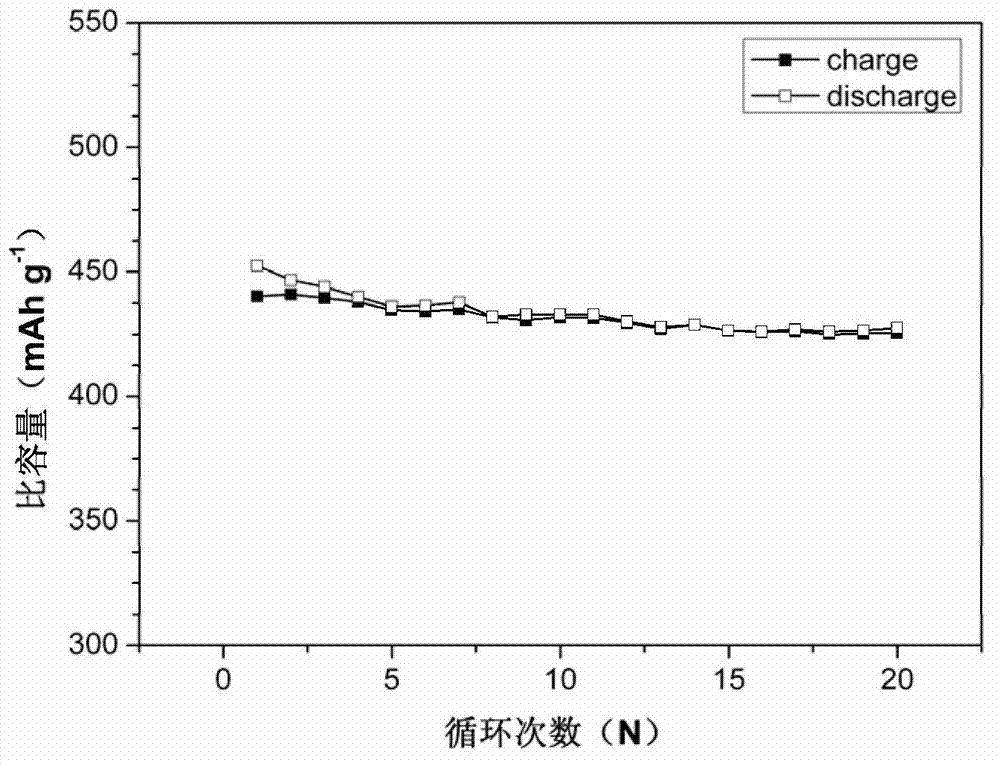

[0041] The invention relates to a graphite / manganous oxide composite electrode material with a core-shell structure and a preparation method thereof, belonging to the fields of inorganic nanometer electrochemistry and new energy. The composite material with core-shell structure is prepared by non-template step-by-step reduction self-assembly, and has a spherical shape. The core-shell structure composed of carbon completely coated manganese oxide nanospheres not only improves the oxidation resistance and electrical conductivity of manganous oxide, but also inhibits the growth of manganous oxide particles, so that it has a uniform particle size (~65nm). The composite material prepared by this method has superior comprehensive electrochemical properties: high actual specific capacity, good cycle stability and good rate performance, and the actual specific capacity can reach ~430mAh / g ( higher than the specific capacity of currently commercialized carbon electrode materials). The...

Embodiment 1

[0101] Slowly add a certain amount of 0.5M potassium permanganate (0.79g) solution into 100mL of glucose (1.8g) for dissolution, stir evenly with magnetic force, and sonicate until the solution turns from purple to brown gel-like solid; then place the brown gel in After drying in an oven at 150°C, grind it into powder; under the protection of nitrogen, the obtained solid powder was pretreated at 300°C for a period of time at a heating rate of 5°C / min, then reacted at a constant temperature of 700°C for 3 hours, and cooled naturally to At room temperature, gray-black graphite / manganese oxide powder is obtained.

Embodiment 2

[0105] Other conditions are the same as in Example 1, except that the calcining temperature is changed to 650°C. The electrochemical test method is the same as in Example 1.

[0106] The gray-black graphite / manganese oxide composite powder obtained according to Example 2 has a uniform particle size, and the particle size is slightly smaller (<60nm) than that of the sample in Example 1, and the carbon content is ~5.6%.

[0107] The initial Coulombic efficiency is 67% (~780mAh / g) at 50mAh / g current, the specific capacity retention rate is 88% after 50 cycles, and the specific capacity is ~420mAh / g at 1600mAh / g charge and discharge current.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com