Method for preparing chitosan by xylose in hemicellulose hydrolysate

A technology of hemicellulose and hydrolyzate, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of undiscovered patent publications, etc., and achieve the effects of simple method, reduced environmental pollution, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

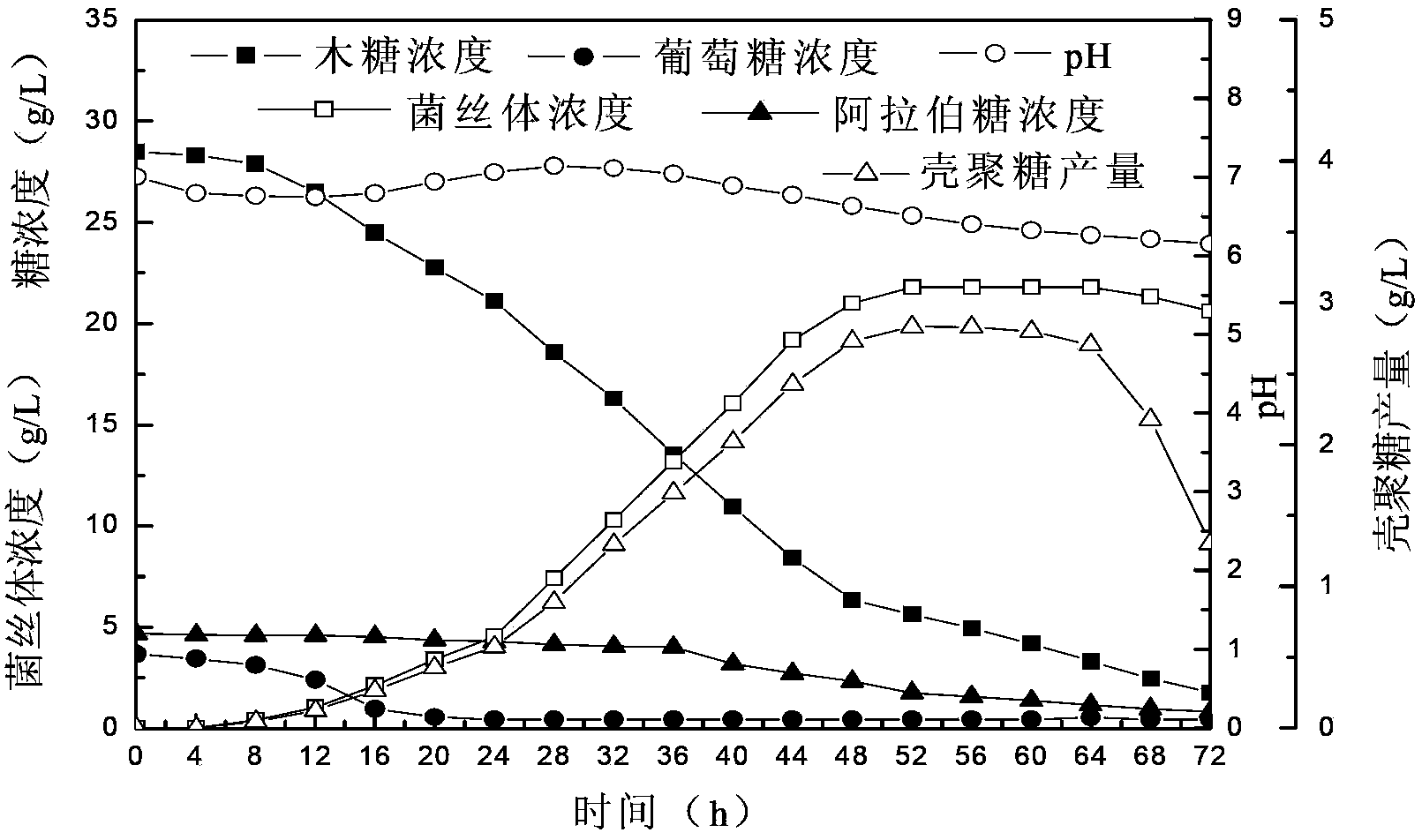

Image

Examples

Embodiment 1

[0033] A method utilizing xylose in hemicellulose hydrolyzate to prepare chitosan, the steps are as follows:

[0034] ⑴Hydrolysis of hemicellulose raw materials: After the corn cob is crushed, it is sieved so that the particle size does not exceed 1mm; the crushed corn cob is mixed with H 2 SO 4 Solution by cob: H 2 SO 4 The solid-to-liquid ratio g:mL of the solution is 1:10, and hydrolyzed in a hydrolysis pot at 120°C for 2 hours to obtain a hemicellulose hydrolyzate;

[0035] (2) Detoxification and decolorization treatment: add Ca(OH) to the hemicellulose hydrolyzate obtained in step (1) 2 Adjust the pH to 10, and obtain a supernatant after solid-liquid separation, and use 10% H in the supernatant 2 SO 4 The pH of the solution is adjusted to 7, and the solid-liquid separation obtains the supernatant; 2 Add activated carbon to the detoxified supernatant at a solid-to-liquid ratio of 1:20 (g:mL), incubate at 50°C for 1 hour, and filter to obtain the detoxified and decolo...

Embodiment 2

[0048] A method utilizing xylose in hemicellulose hydrolyzate to prepare chitosan, the steps are as follows:

[0049] ⑴Hydrolysis of hemicellulose raw materials: After the corn cob is crushed, it is sieved so that the particle size does not exceed 1mm; the crushed corn cob is mixed with H 2 SO 4 Solution by cob: H 2 SO 4 The solid-to-liquid ratio g:mL of the solution is 1:10, and hydrolyzed in a hydrolysis pot at 100°C for 2 hours to obtain a hemicellulose hydrolyzate;

[0050] (2) Detoxification and decolorization treatment: add Ca(OH) to the hemicellulose hydrolyzate obtained in step (1) 2 Adjust the pH to 9, obtain the supernatant after solid-liquid separation, and use 10% H in the supernatant 3 PO 4 The pH of the solution is adjusted to 6, and the solid-liquid separation obtains the supernatant; 2 Add activated carbon to the supernatant after detoxification treatment at a solid-to-liquid ratio of 1:50 (g:mL), incubate at 50°C for 0.5h, filter to obtain hemicellulose ...

Embodiment 3

[0062] A method utilizing xylose in hemicellulose hydrolyzate to prepare chitosan, the steps are as follows:

[0063] ⑴Hydrolysis of hemicellulose raw materials: After the corn cob is crushed, it is sieved so that the particle size does not exceed 1mm; the crushed corn cob is mixed with H 2 SO 4 Solution by cob: H 2 SO 4 The solid-to-liquid ratio g:mL of the solution is 1:10, and hydrolyzed in a hydrolysis pot at 120°C for 3 hours to obtain a hemicellulose hydrolyzate;

[0064] (2) Detoxification and decolorization treatment: add Ca(OH) to the hemicellulose hydrolyzate obtained in step (1) 2 Adjust the pH to 11, obtain the supernatant after solid-liquid separation, and use 10% H in the supernatant 2 SO 4 The pH of the solution is adjusted to 8, and the solid-liquid separation obtains the supernatant; 2 Add activated carbon to the supernatant after detoxification treatment at a solid-to-liquid ratio of 1:25 (g:mL), incubate at 50°C for 2 hours, and filter to obtain hemice...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com