Gradient-coated lithium ion battery graphite cathode material and preparation method thereof

A lithium-ion battery, graphite negative electrode technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of easily damaged shell structure, long cycle, high preparation cost, etc., and achieve large-scale production, simple method, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

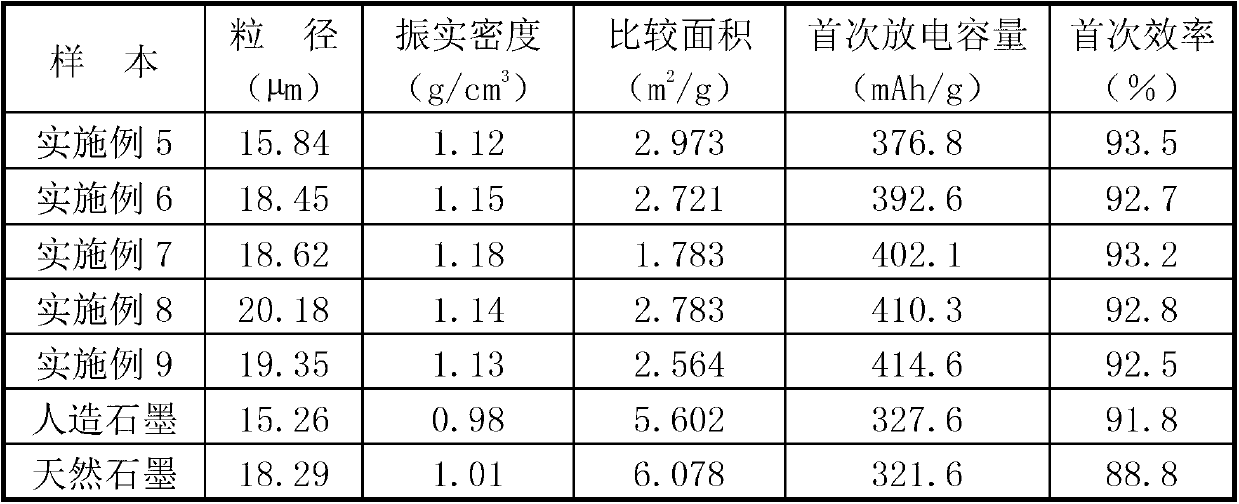

Examples

Embodiment 1

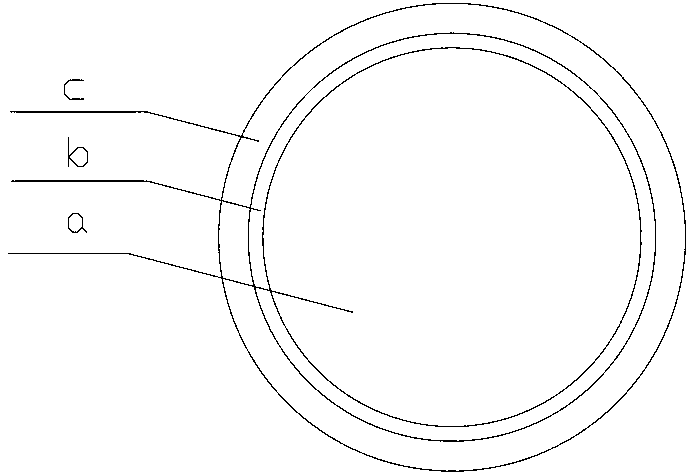

[0031] Example 1: see figure 1 , a lithium-ion battery graphite negative electrode material prepared by ultrasonic spraying gradient coating, including on the surface of graphite powder a, the first layer of coating silicon material b, the second layer of coating carbon material c; its composition is: graphite 100 parts by weight of powder, 1 part by weight of silicon material, and 5 parts by weight of carbon material. 100 parts by weight of graphite powder, 1-10 parts by weight of silicon material, and 5-10 parts by weight of carbon material.

[0032] The graphite powder is artificial graphite powder; the median particle size of the graphite powder is 15-20 μm; the silicon material is silica sol treated at 1000°C-1200°C; the The carbon material is carbonized pitch.

[0033] Silica sol is the source of silicon. After drying at low temperature, it adheres to the graphite powder in the form of nano-silica. After high temperature, a series of chemical reactions occur between si...

Embodiment 2

[0034] Example 2: see figure 1, a gradient-coated lithium-ion battery graphite negative electrode material prepared by ultrasonic spraying, the graphite powder is natural graphite powder; the median particle size of the graphite powder is 15-20 μm. All the other structures are the same as in Example 1. 100 parts by weight of graphite powder, 10 parts by weight of silicon material, and 10 parts by weight of carbon material. The silicon material is silica sol treated at 1000°C to 1200°C; the carbon material is carbonized resin.

Embodiment 3

[0035] Embodiment 3: A gradient-coated lithium-ion battery graphite negative electrode material prepared by ultrasonic spraying, the graphite powder is natural graphite powder; the median particle size of the graphite powder is 15-20 μm. All the other structures are the same as in Example 1. 100 parts by weight of graphite powder, 5 parts by weight of silicon material, and 8 parts by weight of carbon material. The silicon material is silica sol treated at 1000°C to 1200°C; the carbon material is carbonized resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com