Organism medical disposable micro friction motor and manufacture method thereof

A friction generator and biomedical technology, applied in the direction of friction generators, etc., can solve problems that have not been reported, and achieve the effect of simple operation, simple structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

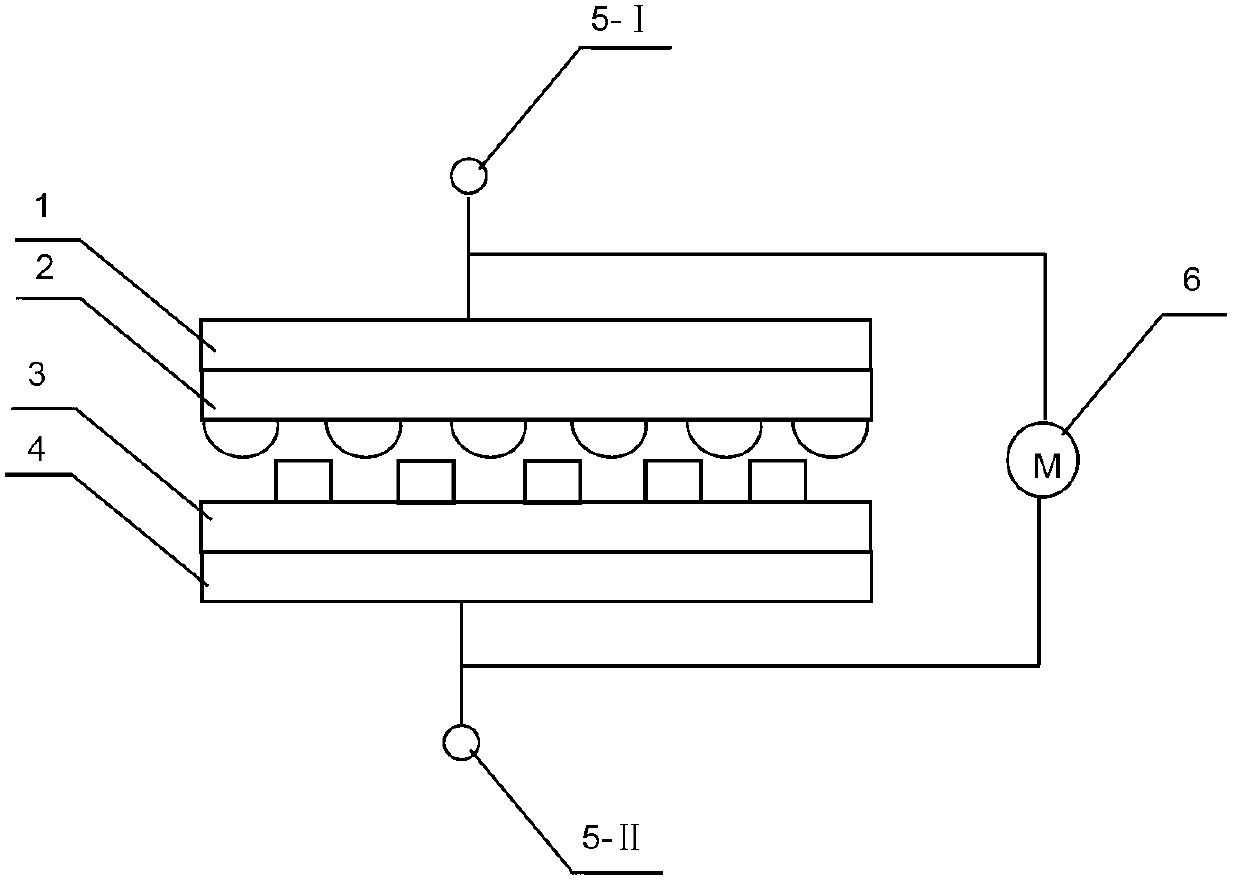

[0032] A biomedical degradable miniature friction generator, such as figure 1As shown, including the upper sheet and the lower sheet, the upper sheet from top to bottom is chitosan with a thickness of 100 μm as the conductive substrate a1 and polydimethylsiloxane with a thickness of 50 μm as the insulating polymer that is easy to obtain electrons Polymer layer 2, the lower sheet from bottom to top is a biodegradable pure iron sheet with a thickness of 200 μm as a conductive substrate b4 and gelatin with a thickness of 50 μm as an insulating polymer layer 3 that is easy to lose electrons, the upper sheet and The two ends of the lower sheet are aligned up and down and packaged separately to ensure that the conductive substrate a and the conductive substrate b are not in contact. The insulating polymer layer 2 that is easy to obtain electrons is engraved with a hemispherical pattern with a laser. The insulating polymer that is easy to lose electrons The polymer layer 3 is laser-e...

Embodiment 2

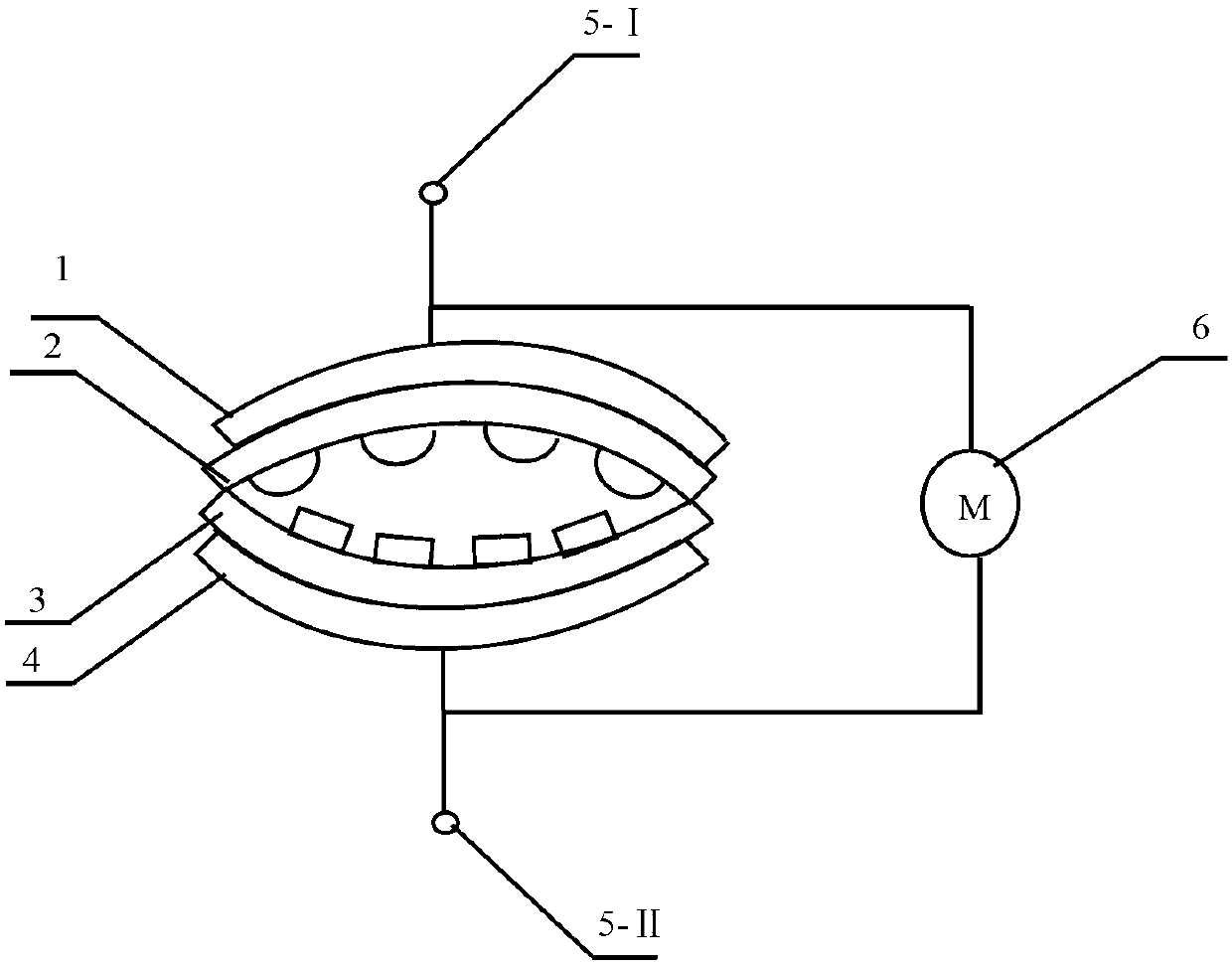

[0043] A biomedical degradable miniature friction generator, such as figure 2 As shown, it includes an upper sheet and a lower sheet. The upper sheet is sequentially composed of polyvinyl alcohol with a thickness of 200 μm as the conductive substrate a1 and polylactic acid with a thickness of 100 μm as the insulating polymer layer 2 that is easy to obtain electrons. From bottom to top, the lower sheet is a biodegradable pure magnesium sheet with a thickness of 300 μm as the conductive substrate b4 and silk protein with a thickness of 60 μm as the insulating polymer layer 3 that easily loses electrons. The two ends of the upper sheet and the lower sheet are up and down. Aligned and packaged separately, the insulating polymer layer 2 that is easy to obtain electrons is engraved with a hemispherical pattern with a laser, and the insulating polymer layer 3 that is easy to lose electrons is engraved with a cylindrical pattern with a laser, and the middle contact The concave and co...

Embodiment 3

[0046] A biomedical degradable miniature friction generator, such as figure 2 As shown, it includes the upper sheet and the lower sheet, and the upper sheet from top to bottom is polycarbonate with a thickness of 200 μm as the conductive substrate a1 and natural cellulose with a thickness of 100 μm as the insulating polymer layer 2 that is easy to obtain electrons , the lower sheet from bottom to top is biodegradable Mg-3wt%Zn-0.5wt%Zr with a thickness of 200 μm as the conductive substrate b4 and elastin with a thickness of 100 μm as the insulating polymer layer 3 that easily loses electrons , the ends of the upper sheet and the lower sheet are aligned up and down and packaged separately, the insulating polymer layer 2 that is easy to obtain electrons is engraved with a hemispherical pattern, and the insulating polymer layer 3 that is easy to lose electrons is engraved by laser A cylindrical pattern pattern is formed, and the concave-convex pattern of the intermediate contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com