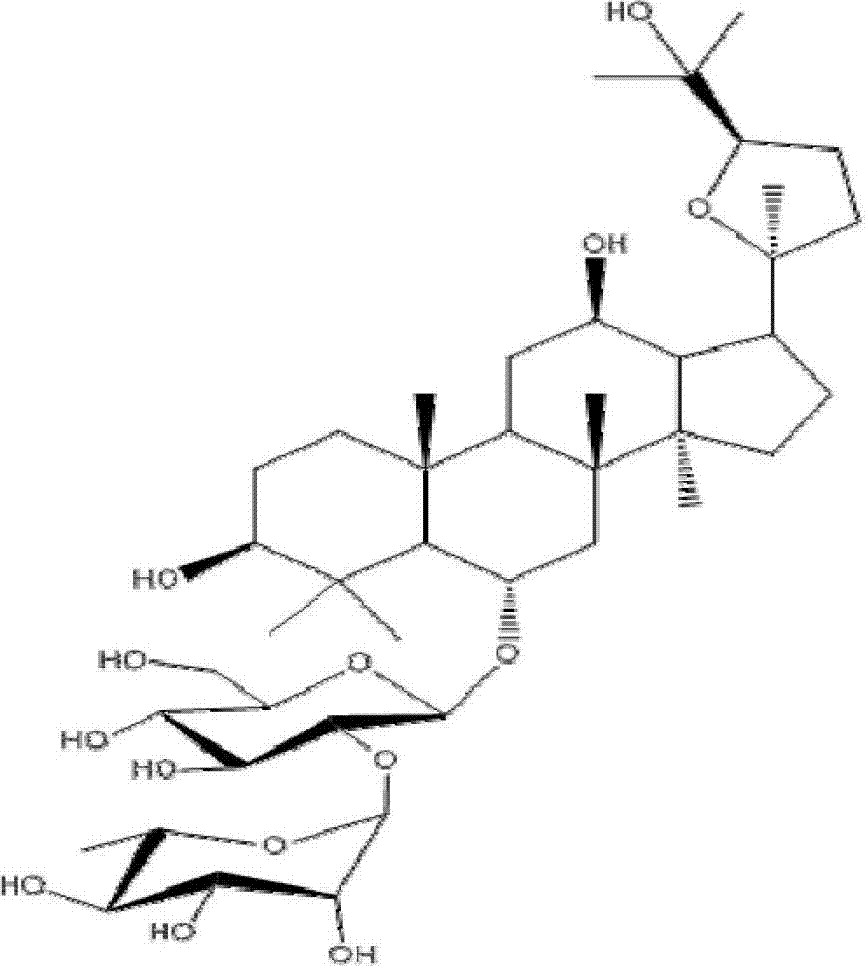

Pseuoginsenoside F11 phospholipid complex as well as preparation method and application thereof

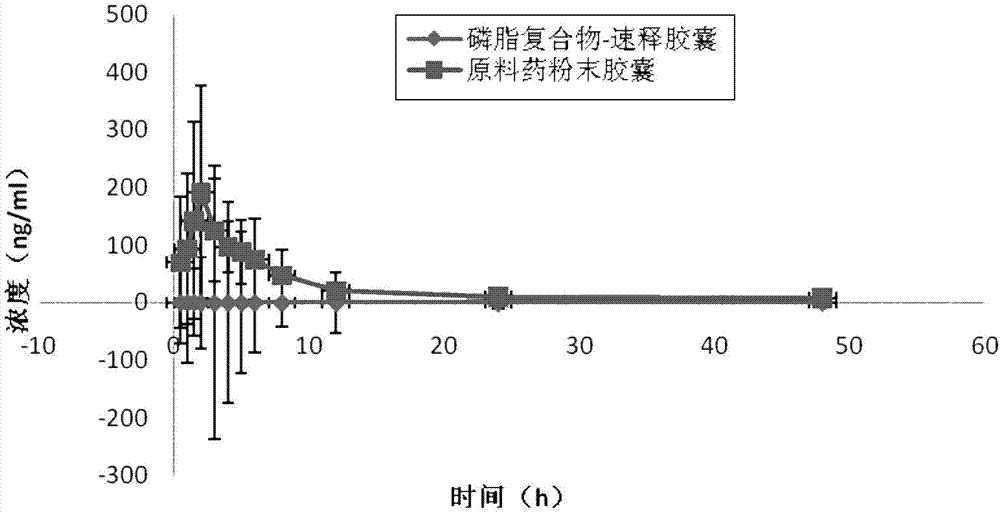

A technology for simulating ginsenoside and phospholipid complexes, which is applied in the directions of pharmaceutical combinations, pharmaceutical formulations, and inactive medical preparations, etc., to achieve the effects of facilitating industrial production, improving oral bioavailability, and enhancing curative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

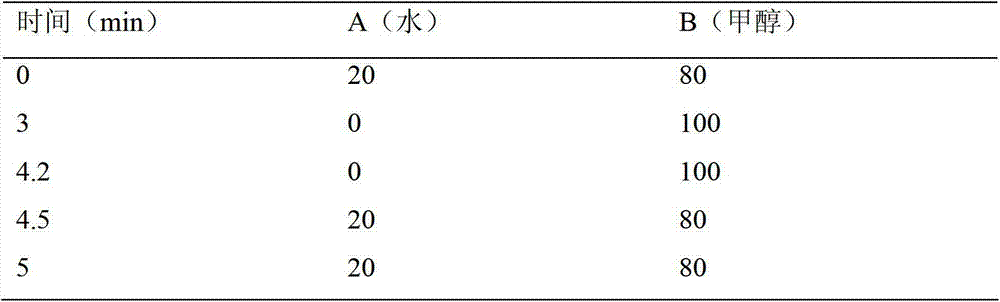

Method used

Image

Examples

preparation example Construction

[0043] A method for preparing the phospholipid complex of pseudo-ginsenoside F11 as described above, characterized in that: the steps are as follows:

[0044] (1) Uniformly disperse the phospholipids in the aqueous solution of the hydrophilic carrier by magnetic stirring;

[0045](2) Add pseudo-ginsenoside F11 into the aqueous solution of hydrophilic excipients dispersed with phospholipids in 2-6 times according to the above ratio, and pass through at 1500r·min -1 Grinding in a high-speed grinding machine for 1h-6h to prepare the grinding suspension of the phospholipid complex of pseudoginsenoside F11.

[0046] During the preparation of the above-mentioned grinding suspension, the pseudo-ginsenoside F11 was added to the aqueous solution of hydrophilic adjuvant dispersed with phospholipids in 4 times, at 1500r min -1 Grind for 3 hours in a grinder running at high speed.

[0047] Pharmaceutically acceptable excipients should be added to the grinding suspension of the phospholi...

Embodiment 1

[0060] Grinding suspension of pseudoginsenoside F11: 30g of pseudoginsenoside F11, 300g of hydrogenated soybean lecithin, 30g of hydroxypropyl cellulose (HPC), 270g of distilled water; Propyl cellulose aqueous solution; take 300g of hydrogenated soybean lecithin and evenly disperse in the hydroxypropyl cellulose aqueous solution; weigh 30g of pseudoginsenoside F11 crude drug, divide it into 2 batches of feeding, and place it together with the above-mentioned hydroxypropyl cellulose aqueous solution in the grinding In the cup, at 1500r·min -1 Grind for 3 hours in a grinding machine running at high speed to obtain the pseudo-ginsenoside F11 phospholipid complex grinding suspension (hereinafter referred to as: pseudo-ginsenoside F11 grinding suspension). After grinding, the average particle size of pseudoginsenoside F11 raw material is reduced to less than 1 μm under a microscope.

Embodiment 2

[0062] Grinding suspension of pseudoginsenoside F11: 150g of pseudoginsenoside F11, 75g of soybean lecithin, 5g of hydroxypropyl cellulose (HPC), 45g of distilled water; Propyl cellulose aqueous solution; take 75g of soybean lecithin and evenly disperse in the hydroxypropyl cellulose aqueous solution; weigh 50g of pseudoginsenoside F11 crude drug, divide it into 2 batches of feeding, and place it together with the above-mentioned hydroxypropyl cellulose aqueous solution in the grinding In the cup, at 1500r·min -1 Grind for 1 hour in a high-speed grinding machine to obtain a grinding suspension of pseudoginsenoside F11. After grinding, the average particle size of pseudoginsenoside F11 raw material is reduced to less than 1 μm under a microscope.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com