Acidolysis process in titanium dioxide production process

A production process, titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of unavoidable moisture, high maintenance costs, high energy consumption of the system, to avoid a large amount of mineral powder dust, small one-time investment , The effect of simple acid hydrolysis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

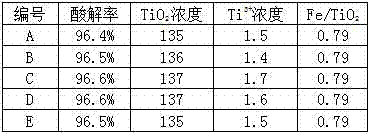

Embodiment 1

[0024] Coarse titanium concentrate and sulfuric acid (titanium white recovery waste acid) with a mass percentage concentration of 20% enter the ball mill for wet grinding at a mass ratio of 1:9. The inner diameter of the ball mill is 2600m, and the inner lining thickness is 50mm. The grinding medium is 304 stainless steel balls with a diameter of 60mm, and the working speed is 30r / min. The remaining 10% of the 325 mesh sieve of the titanium concentrate in the obtained titanium concentrate slurry is injected into the acid hydrolysis pot with the qualified titanium concentrate sulfuric acid slurry , add metered concentrated sulfuric acid to initiate the main reaction, after aging, leaching and reduction to obtain acid liberated material sample A, its detection indicators are shown in Table 1.

Embodiment 2

[0026]Coarse titanium concentrate and 35% sulfuric acid enter the ball mill at a mass ratio of 7:3 for wet grinding. The inner diameter of the ball mill is 2600m, and the inner lining is 304 stainless steel plate with a thickness of 50mm. The grinding medium in the machine is 304 stainless steel ball with a diameter of 60mm. The rotating speed is 30r / min, and the remaining 12% of the 325-mesh sieve of the titanium concentrate in the obtained titanium concentrate slurry is injected into the acid hydrolysis pot with the qualified titanium concentrate sulfuric acid slurry, and the metered concentrated sulfuric acid is added to initiate the main reaction, and then matured , leached and reduced to obtain acid liberated material sample B, and its detection indicators are shown in Table 1.

Embodiment 3

[0028] Coarse titanium concentrate and 45% sulfuric acid enter the ball mill for wet grinding at a mass ratio of 4:6. The inner diameter of the ball mill is 2600m, and the inner lining is 304 stainless steel plate with a thickness of 50mm. The grinding medium in the machine is 304 stainless steel ball with a diameter of 60mm. The rotating speed is 30r / min, and the remaining 18% of the 325 mesh sieve of the titanium concentrate in the obtained titanium concentrate slurry is injected into the acid hydrolysis pot with the qualified titanium concentrate sulfuric acid slurry, and the metered concentrated sulfuric acid is added to initiate the main reaction, and then matured , leached and reduced to obtain acid liberated material sample C, and its detection indicators are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com